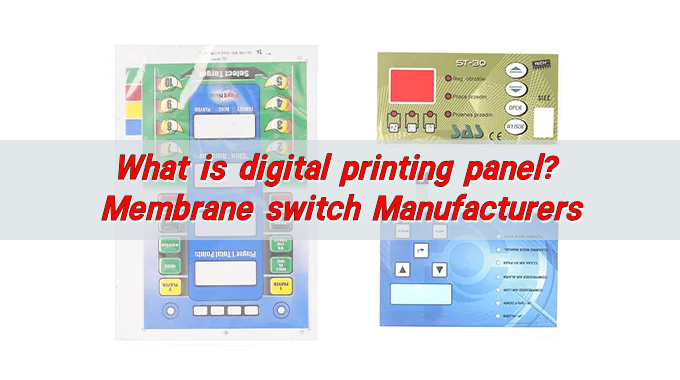

What is Digital Printing Panel? Membrane Switch Manufacturers

What is Digital Printing Panel? Membrane Switch Manufacturers

Digital printing panel is a modern process that uses digital printing technology to print high-precision patterns on the surface of various materials. In the manufacture of membrane switches, digital printing panel technology can be used to print exquisite patterns and texts on the surface of the membrane, improving the visual effect and operating experience of the membrane switch.

As a professional membrane switch manufacturer, Yu An Electronics has rich experience and excellent capabilities in digital printing panels. It can apply digital printing technology to the manufacture of membrane switches and provide customized solutions for customers. Our digital printing panels are not only high-precision and colorful, but also ensure the durability and reliability of membrane switches in various environments.

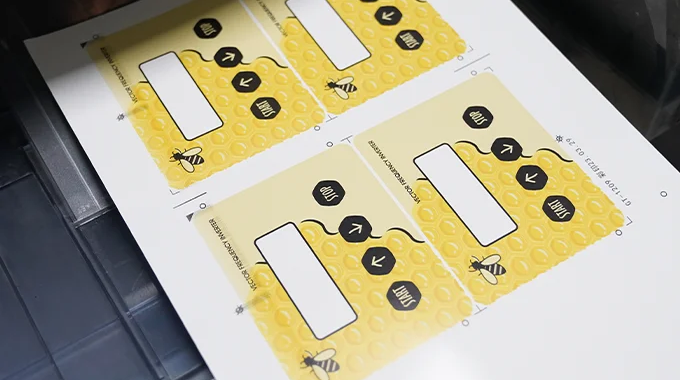

What is Digital printing membrane switch?

Digital printing membrane switch is an advanced user interface used in various electronic devices. Unlike conventional printing methods, digital printing directly applies ink onto the graphic overlay, producing high-resolution images without additional processing steps.

Membrane switches are widely used in medical devices, industrial equipment, and consumer electronics. The digital printing process ensures clear, readable labels, detailed icons, and visually appealing branding.

With no color limitations, digital print panels provide virtually endless design possibilities. Manufacturers can modify designs instantly without extra costs. Whether it’s a single prototype or a large production run, digital printing adapts effortlessly.

Is digital printing as good as screen printing?

This is a common question in the industry. Both methods have their advantages, but digital printing excels in areas where screen printing falls short.

- Detail & Resolution: Digital printing delivers intricate, multi-color designs with photorealistic clarity.

- Customization: Screen printing requires new stencils for each change, increasing costs. Digital printing makes it easy.

- Speed & Efficiency: No setup time means digital printing starts immediately. Screen printing requires screens, drying time, and multiple steps for color layering.

- Cost: Digital printing is cost-effective for short runs. Screen printing is more economical for large quantities but involves high initial setup expenses.

While screen printing lasts longer in extreme environments due to its thick ink layers, digital printing has evolved. Today’s UV-cured inks and protective coatings significantly enhance durability.

For applications requiring frequent design updates, digital printing wins. For rugged industrial use, screen printing may be the better choice.

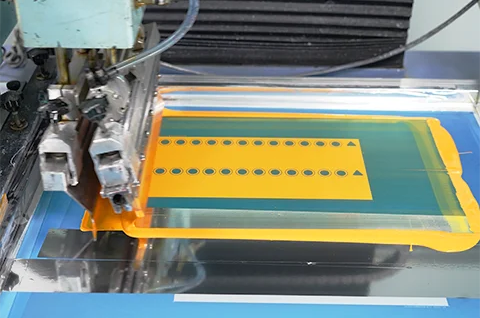

What machine is used for digital printing?

Digital printing relies on specialized machines built for precision and durability. The three most commonly used types are:

- Inkjet Printers: These apply tiny ink droplets directly onto materials. Ideal for producing smooth gradients and high-definition graphics.

- UV Flatbed Printers: A top choice for membrane switch manufacturing. These use UV light to cure ink instantly, ensuring strong adhesion to plastic, polyester, and polycarbonate.

- Laser Printers: Less common for membrane switches but excellent for fine-detail work and long-lasting prints.

Most manufacturers prefer UV flatbed printers due to their superior adhesion, durability, and ability to print on various surfaces.

What is the best material for digital printing?

Choosing the right material ensures durability, clarity, and ink adhesion. In membrane switch production, three materials stand out:

- Polyester (PET): The industry favorite. Highly durable, resistant to moisture and chemicals, and perfect for high-use applications.

- Polycarbonate (PC): Known for its strength and transparency, commonly used in medical and industrial interfaces.

- Vinyl (PVC): More affordable but less durable, suitable for short-term applications.

Polyester remains the top choice. Its resilience, combined with excellent ink absorption, ensures that digital print panels maintain their appearance and function over time.

Why is digital printing cheap?

One of the biggest advantages of digital printing is cost efficiency. Here’s why:

- No Setup Costs: Traditional printing methods require stencils, screens, and multiple processing steps. Digital printing eliminates these expenses.

- Less Waste: Only the necessary amount of ink and material is used, reducing production waste.

- Short Runs are Affordable: Businesses don’t need to order in bulk to justify costs. Even small batches remain cost-effective.

- Faster Turnaround: No drying time, no screen changes, and no labor-intensive processes mean faster delivery times.

For companies needing fast, affordable customization, digital printing is the ultimate solution.

What lasts longer, screen printing or digital printing?

Durability matters, especially for industrial and medical devices. Screen printing traditionally lasts longer due to its thicker ink layers, which resist abrasion and chemical exposure.

However, digital printing has evolved. Advanced UV-resistant inks, protective coatings, and high-quality materials have significantly improved lifespan. For most applications, digital print panels now offer comparable longevity to screen-printed designs.

In harsh conditions—like outdoor use or heavy industrial environments—screen printing still holds an edge. But for most indoor and moderate-use applications, digital printing lasts long enough while providing unmatched design flexibility.

What are the disadvantages of digital printing?

Though digital printing offers numerous benefits, it does have some limitations.

- Ink Thickness: Digital prints use thinner ink layers compared to screen printing, which can affect durability in high-friction areas.

- UV Exposure: While modern UV-resistant inks improve longevity, excessive sunlight can still cause slight fading over time.

- Higher Cost for Large Runs: If mass-producing identical designs, screen printing may be more cost-effective due to bulk processing efficiencies.

However, the industry continues to innovate. Many manufacturers apply lamination or clear protective coatings to enhance durability. These solutions address most of digital printing’s traditional drawbacks.

Conclusion:

Digital printing panels have revolutionized membrane switch manufacturing. They provide high-resolution graphics, cost savings, and design flexibility. Businesses benefit from faster production, reduced waste, and effortless customization.

While screen printing remains ideal for rugged environments, digital printing offers unbeatable efficiency and versatility. Advances in ink technology and protective coatings are closing the durability gap.

Need expert advice on digital printing membrane switches? Contact us at sales@best-membraneswitch.com today!

Tags:

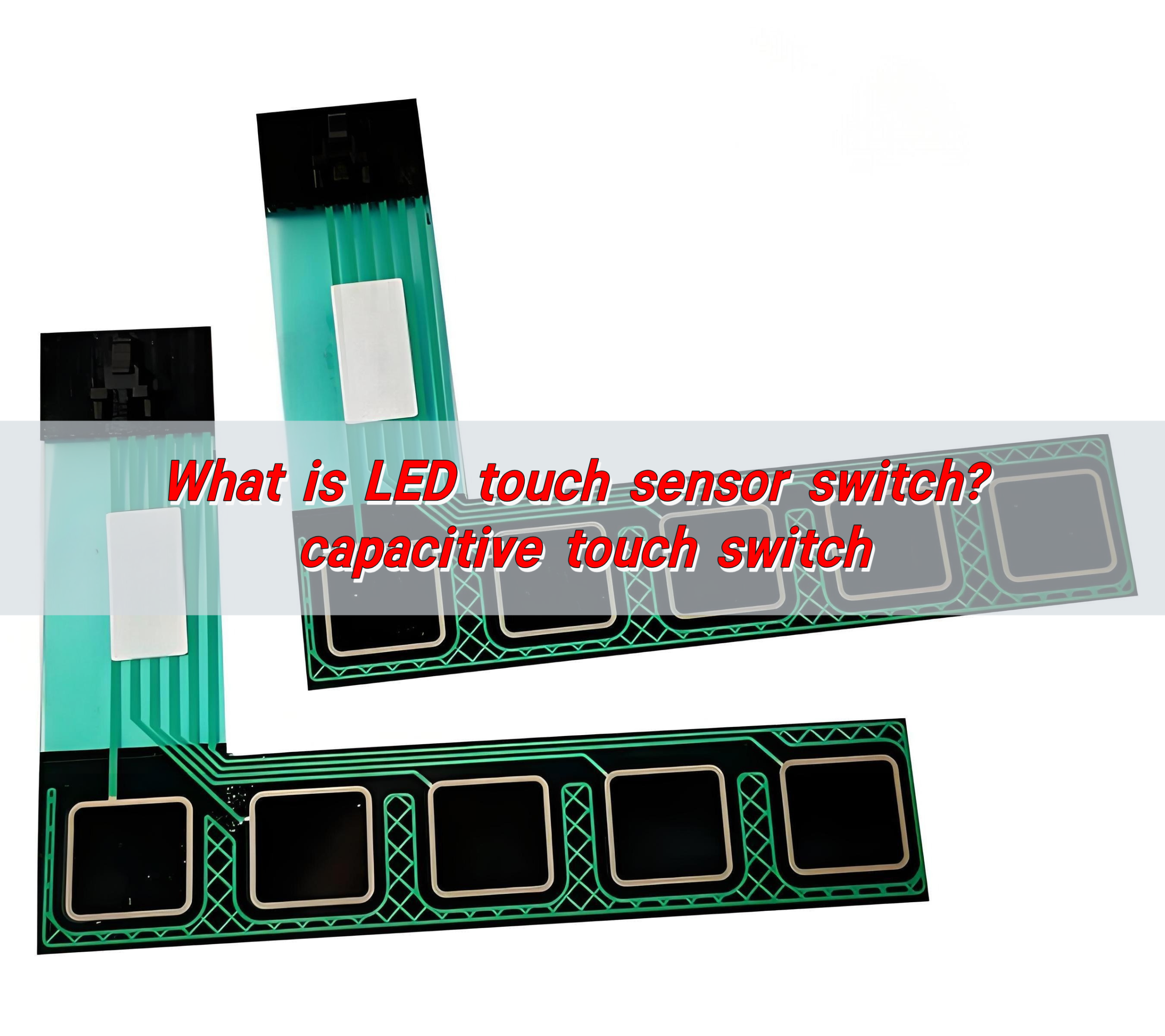

What is LED touch sensor switch? capacitive touch switch

The LED touch sensor switch is an electronic component that combines an LED light and a touch sensor. It controls the on and off of the LED light by touching it, achieving energy-saving and convenient lighting control. It uses capacitive sensing technology to detect human proximity or touch, thereby controlling the on and off of ...

What is IP66 Waterproof? Waterproof Rating of Membrane Switches

The IP66 waterproof rating means that the device is completely protected from dust ingress and can withstand strong water jets. The waterproof rating of membrane switches can usually reach IP67, which is achieved through special processes and materials to ensure its reliability in humid or rainy environments. This performance makes membrane switches suitable for scenes ...

Why are flexible membrane switches a popular choice in modern electronics?

Flexible membrane switches are popular in modern electronic products due to their flexibility, thinness and economy. They not only adapt to complex curved surfaces and achieve flexible design, but also have environmental adaptability such as waterproof and dustproof. In addition, they support multi-function integration, such as LED indicators and sound feedback, to enhance user experience. ...

Contact us online