What is a Product Identification Label?

What is a Product Identification Label?

What is a Product Identification Label?

A product identification label membrane panel is a crucial part of any product. It conveys important information about the item, such as its brand, specifications, and manufacturing details. These labels are used across various industries to enhance product recognition and ensure compliance with legal and safety standards.

What are the Four Types of Product Labels?

Product labels can be classified into four main types:

- Brand Labels: These labels display the name or logo of a company. They strengthen brand identity and are often the first thing customers notice.

- Descriptive Labels: These labels provide details about the product, such as size, color, or material. They help consumers make informed decisions.

- Informational Labels: These labels include data such as usage instructions, expiration dates, or safety warnings. They ensure proper use and help maintain safety standards.

- Grade Labels: These labels indicate the quality level of a product. They are common in items like food or industrial materials, where quality can vary.

What Information is Contained on a Product Identification Label?

A product identification label typically includes:

- Brand Name: Establishes the product’s maker.

- Product Name and Description: Provides clarity on what the item is.

- Serial or Batch Number: Helps track production details.

- Compliance Marks: Displays certifications or regulatory approvals.

- Manufacturing Details: Indicates where and when the product was made.

- Usage Instructions: Guides consumers on how to use the product.

- Safety Warnings: Alerts users to potential risks.

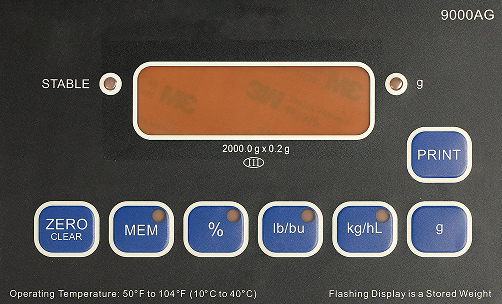

What is a Product Identification Label in Membrane Switch Design?

In membrane switch design, product identification labels serve a dual purpose. They identify the device and contribute to its functionality. Often integrated into the membrane switch, these labels ensure durability and enhance aesthetic appeal.

Such labels must withstand wear and tear, exposure to harsh environments, and frequent usage. They are made from high-quality materials like polycarbonate or polyester to ensure longevity. Custom designs allow for creative branding and user-friendly layouts, combining utility with visual impact.

How to Manufacture a Product Identification Label Membrane Switch?

The manufacturing process for a product identification label membrane switch involves several precise steps. Each phase is crucial to ensure the final product meets durability, functionality, and aesthetic standards. Here’s an in-depth look at the process:

1. Material Selection

Choosing the right materials is the foundation of a high-quality membrane switch with a product identification label. Commonly used materials include polyester (PET) and polycarbonate (PC).

2. Graphic Design and Artwork Development

- Branding elements: Logos, product names, and company information.

- Operational details: Labels for buttons, indicators, and instructions.

- Color schemes: Vibrant, fade-resistant colors for clear visibility and aesthetics.

3. Printing

- Screen Printing: A durable and cost-effective method ideal for high-volume production. It uses layers of ink to achieve vibrant colors and clear images.

- Digital Printing: This method offers high-resolution results and is well-suited for complex designs or small production runs. It enables greater flexibility in terms of customization.

4. Surface Treatment and Finishing

Protective coatings such as UV or anti-scratch layers are applied to prevent wear and fading. Textured finishes can also be added for improved grip or a premium look.

5. Lamination

Lamination involves adding a protective overlay to the printed material. This layer shields the graphics from environmental factors like moisture, chemicals, and physical wear.

6. Die Cutting and Precision Shaping

Die cutting shapes the label to match the product’s design specifications. Modern machines use precision cutting tools to create clean edges and ensure a perfect fit.

7. Adhesive Application

An adhesive backing is applied to the label to enable secure attachment to the membrane switch assembly.

8. Assembly

The label is then assembled with the other layers of the membrane switch, including the circuit layers, tactile domes, and spacer layers.

9. Quality Control and Testing

- Adhesion strength: Ensures the label stays intact over time.

- Graphic clarity: Confirms that printed details are clear and legible.

- Durability: Tests resistance to environmental factors, wear, and tear.

- Functionality: Verifies that buttons, indicators, and other operational elements work seamlessly.

10. Packaging and Delivery

Once tested, the finished membrane switch with its product identification label is carefully packaged to prevent damage during transit.

Why is a Product Identification Label Important in Material Selection?

Selecting the right material for a product identification label is crucial. The material affects the label’s durability, appearance, and performance. Factors to consider include:

- Environmental Resistance: The label should withstand temperature changes, humidity, and UV exposure.

- Chemical Resistance: Essential for products used in industrial or medical settings.

- Adhesive Strength: Ensures the label stays intact throughout the product’s lifecycle.

- Aesthetic Appeal: Enhances the product’s overall appearance.

High-quality materials not only improve the label’s lifespan but also maintain its readability and visual appeal over time.

FAQs

1. What materials are used for product identification label membrane panels?

Common materials include polyester and polycarbonate, known for their durability, chemical resistance, and flexibility. These materials ensure the panel can withstand harsh environments and frequent use.

2. Can product identification label membrane panels be customized?

Yes, these panels can be fully customized. Companies can choose the color, shape, size, branding, and layout to meet their specific product and branding needs.

3. How are the graphics printed on these panels?

Graphics are typically printed using techniques like screen printing or digital printing. These methods provide high-resolution images and vibrant colors that are resistant to fading or wear.

4. Are product identification label membrane panels weather-resistant?

Yes, they are designed to resist extreme weather conditions, UV exposure, moisture, and temperature fluctuations. This makes them suitable for both indoor and outdoor applications.

5. How are these panels integrated into membrane switches?

The panels are laminated onto the membrane switch assembly using adhesives or bonding techniques. This process ensures a seamless and secure fit, enhancing both durability and aesthetics.

6. Can these panels include functional features?

Yes, product identification label membrane panels can incorporate functional features like windows for displays, embossed buttons, or tactile feedback areas, combining utility with branding.

How to clean silicone rubber? Silicone Rubber Membrane Switch

How to clean silicone rubber? To clean the silicone rubber membrane switch, use a mild detergent and a soft cloth. First, turn off the power and remove the keycaps. Use a slightly damp soft cloth to gently wipe the switch and surrounding areas to remove dust and stains. If the stains are stubborn, wipe with ...

IP65 vs IP67: What Are the Differences?

IP65 vs IP67? The IP65 protection level provides complete dust protection for the device and can withstand low-pressure water jets from all directions, making it suitable for ordinary outdoor environments. Based on this, IP67 allows the device to be immersed in 1 meter of water for a short period of time (usually 30 minutes) without ...

Mechanical vs Non Mechanical Keyboard: What’s the Difference?

The main differences between mechanical keyboards and non-mechanical keyboards (such as membrane keyboards) are structure, feel, durability and sound. Each key of a mechanical keyboard has an independent switch, providing a clear feel and tactile feedback, strong durability, louder sound, and is suitable for gamers. Non-mechanical keyboard keys contact the circuit board through a rubber ...

Contact us online