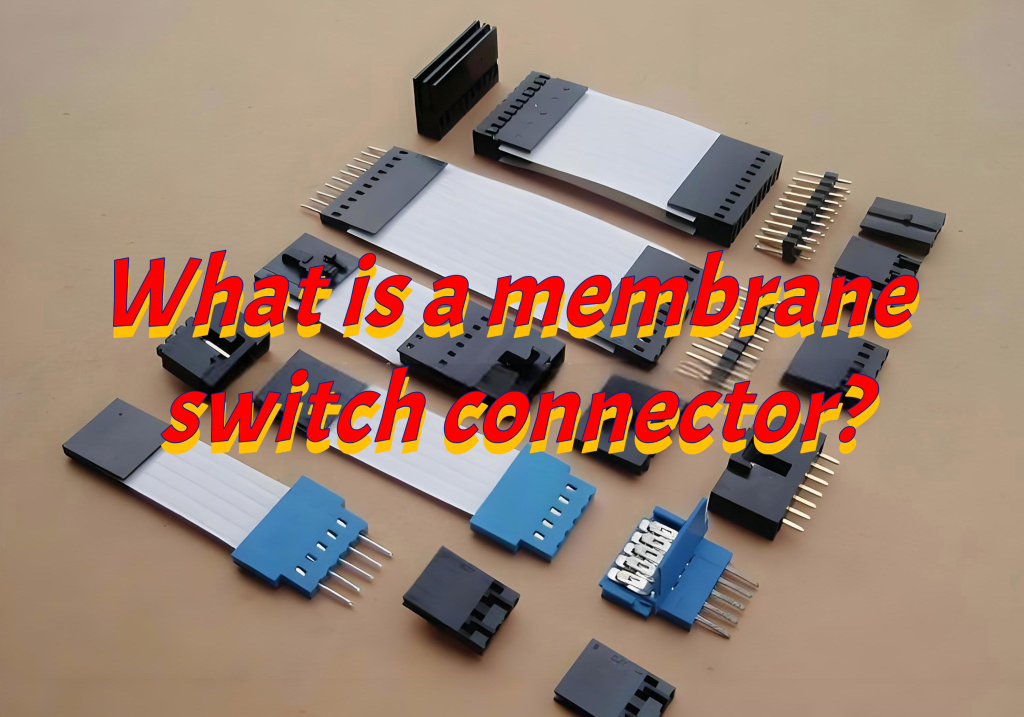

What is a membrane switch bar and board connector?

What is a membrane switch bar and board connector?

What is a membrane switch bar and board connector? A membrane switch bar and board connector is a connector specifically used to connect membrane switches and other electronic components. It is a bridge connecting membrane switches and other electronic components to ensure stable signal transmission and normal operation of equipment.

What is a bar and board connector?

A membrane switch bar and board connector is an electronic connector used to connect membrane switches and other electronic components (such as flexible circuit boards FPC, flat cables FFC, etc.).

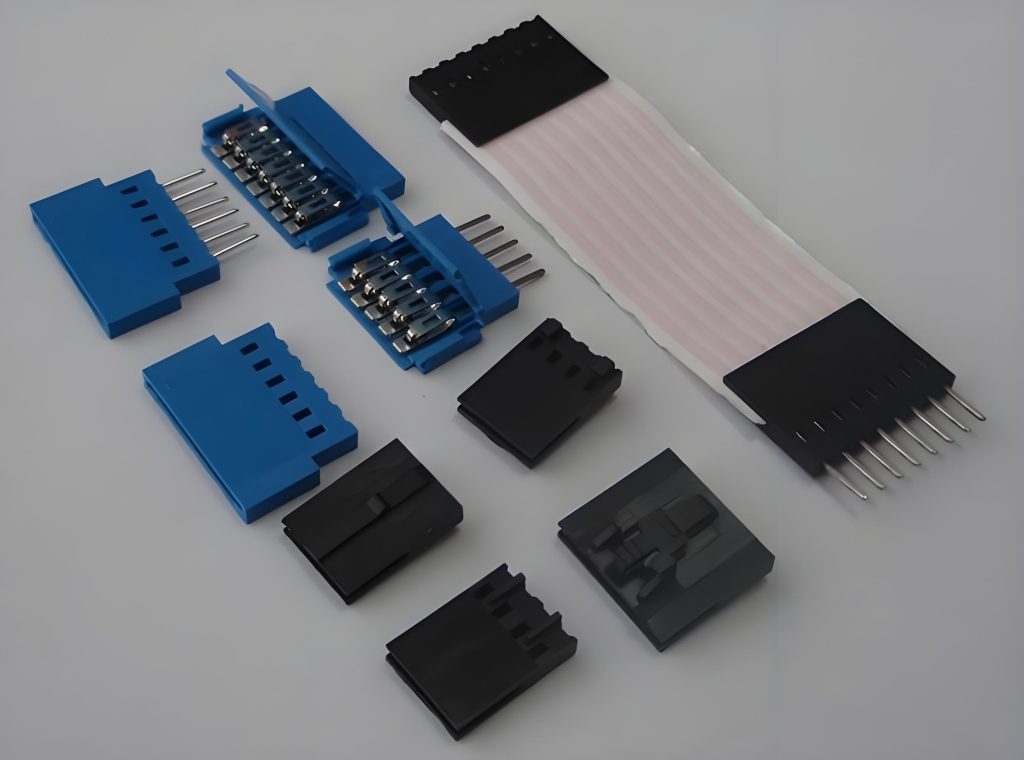

1. Structural composition:

- Shell: Usually made of insulating plastic material, it protects internal contacts and fixes the connector. The shape and size of the shell vary to suit different application scenarios and installation requirements. For example, some bar and board connector shells are designed as bars, which are convenient for installation in narrow spaces; others have a locking structure to ensure the firmness of the connection.

- Contact: This is the core component of the connector, which is used to achieve circuit conduction. Contacts are generally made of metal materials, such as copper alloys, which have good conductivity and elasticity. Its design usually adopts a piercing structure. When connected to a membrane switch or FPC/FFC, the contact can pierce the insulation layer and closely contact the internal conductive circuit to ensure stable signal transmission.

2. Working principle:

The membrane switch strip connector contacts the conductive circuit on the membrane switch or FPC/FFC through its contact to establish a circuit connection. When the current or signal is transmitted to the connector through the membrane switch, the contact transmits the current or signal to the other end of the electronic component connected to it, thereby realizing the conduction of the circuit. This connection method is simple and reliable, and can meet the requirements of electronic equipment for signal transmission.

3. Features and advantages:

- Small size and light weight: It is very suitable for electronic devices with limited space, such as mobile phones, tablets, laptops, etc. Its small size can achieve circuit connection without taking up too much space.

- Reliable connection: The piercing structure of the contact can ensure a close connection with the membrane switch or FPC/FFC, and is not prone to looseness or poor contact, ensuring the stability of signal transmission.

- Easy to install: Generally, plug-in or welding installation methods are adopted, which are simple and convenient to operate and can improve production efficiency. For plug-in connectors, you only need to insert it into the corresponding slot to complete the installation; for welding connectors, it is fixed on the circuit board through welding process, and the connection is firm and reliable.

What is a busbar connector?

In membrane switches, busbar connectors are an important component used to connect busbars (usually conductive strips) in membrane switch circuits.

1. Structure and composition

Busbar connectors generally consist of the following main parts:

- Contact part:

This is the part that directly contacts the busbar of the membrane switch, usually made of metal materials with good conductive properties, such as copper or copper alloy. The design of the contact part usually adopts an elastic structure, which can ensure close contact with the busbar to achieve good electrical connection.

The shape and size of the contact part will be designed according to the type and specification of the busbar. For flat busbars, the contact part may be a flat sheet structure; for round busbars, the contact part may be a round needle structure.

- Insulating shell:

The shell is usually made of insulating materials, such as plastic, and its function is to isolate the contact part from the external environment to prevent short circuits and leakage. The insulating shell can also fix and protect the contact part to ensure that the connector will not be damaged during use.

The design of the shell usually takes into account the convenience and stability of installation.

- Connecting leads:

The connecting leads are used to connect the busbar connector to the external circuit. The leads are usually made of metal wires with good conductivity, such as copper wire. The length and specifications of the leads can be selected according to actual needs.

The connection methods of the leads usually include welding, crimping, etc. The welding method can provide a relatively firm connection, but requires certain welding technology and equipment; the crimping method is relatively simple and fast, and is suitable for large-scale production.

2. Working principle

The working principle of the busbar connector is mainly to achieve electrical connection between the contact part and the busbar of the membrane switch, thereby transmitting current or signal from the busbar to the external circuit.

When the busbar connector contacts the busbar, the elastic structure of the contact part will provide a certain pressure to ensure good contact.

At the same time, the insulating shell isolates the contact part from the external environment to prevent short circuit and leakage. The connecting lead transmits the current or signal to the external circuit to realize the connection between the membrane switch and other devices.

3. Features and advantages

- High reliability:

The design of the busbar connector usually takes into account various use environments and conditions, and has high reliability. For example, the elastic structure of the contact part can ensure good contact under different temperature, humidity and vibration conditions; the insulating shell can effectively prevent short circuit and leakage, and improve the safety of the connection.

Some high-quality busbar connectors have also undergone rigorous testing and certification to ensure that they can work stably and reliably in various application scenarios.

- Easy to install and maintain:

Busbar connectors usually adopt plug-in or crimping installation methods, which are simple and convenient to operate without complex tools and techniques. This enables the busbar connector to be quickly installed and replaced during the production and maintenance of the membrane switch, improving production efficiency and maintenance convenience.

Some busbar connectors are also designed with an anti-misinsertion structure to avoid incorrect operations during installation and further improve the reliability of installation.

- Good electrical performance:

The contact part of the busbar connector is made of metal material with good conductivity, which can ensure low resistance and low loss electrical connection. At the same time, reasonable design and manufacturing process can reduce signal interference and attenuation and improve the quality of signal transmission.

For some membrane switch applications that need to transmit high-frequency signals, the busbar connector can also adopt special designs, such as shielding structure, impedance matching, etc., to meet the requirements of high-frequency signal transmission.

What is a power board connector?

In a membrane switch, the power board connector is a key component connecting the membrane switch and the power board.

- 1. Structure and composition

It is usually composed of a metal contact part with good conductivity, an insulating shell and a connecting lead. The contact part may be in the form of a pin, a jack or a spring sheet to ensure reliable contact with the membrane switch and the power board.

The insulating shell protects the contact part and provides mechanical support. Its shape and size are designed according to actual needs. The connecting lead is used to connect the external circuit, and the connection methods include welding, crimping or plugging.

- 2. Working principle

Establish an electrical connection with the membrane switch and the power board through the contact part. When the membrane switch is pressed, the signal is transmitted to the power board through the connector, triggering the corresponding circuit function, and the power board provides power to the membrane switch through the connector.

- 3. Features and advantages

Reliable power transmission: The contact part has good conductivity, and reasonable design can reduce resistance and energy loss, and improve transmission efficiency.

Compact design: Adapt to the limited space environment of membrane switch application, and the miniaturized structure does not take up too much space.

Easy to install and maintain: The plug-in or welding installation method is simple to operate, which is convenient for quick installation and replacement during maintenance on the production line. Some plug-in connectors have locking mechanisms to ensure a firm connection and easy disassembly.

Good compatibility: Compatible with different types of membrane switches and power boards, standardized interfaces and sizes improve versatility and interchangeability.

What does a membrane switch connector consist of?

Membrane switch connectors are mainly composed of the following parts:

1. Contact parts

- Conductive material: Generally a metal with good conductivity, such as copper alloy. Ensure stable transmission of current and signals between membrane switches and other electronic components.

- Elastic structure: usually in the form of spring pins, cantilever beams, etc., which provide appropriate pressure during connection to ensure close contact with the conductive layer of the membrane switch.

2. Insulating shell

- Material: Plastics with good insulation properties, such as polycarbonate, nylon, etc., are used to prevent short circuits and protect internal contact parts.

- Structure: The shape and size are designed according to different application scenarios to meet space requirements and protection requirements.

3. Connecting leads

- Conductive materials: Mostly metal wires with good conductivity, such as copper wire. Its specifications and lengths are selected according to the connection distance and current requirements.

- Connection method: Common ones include welding, crimping and plug-in, each with its own characteristics to meet different installation and use requirements.

What types of membrane switch connectors are there?

Membrane switch connectors are mainly of the following types:

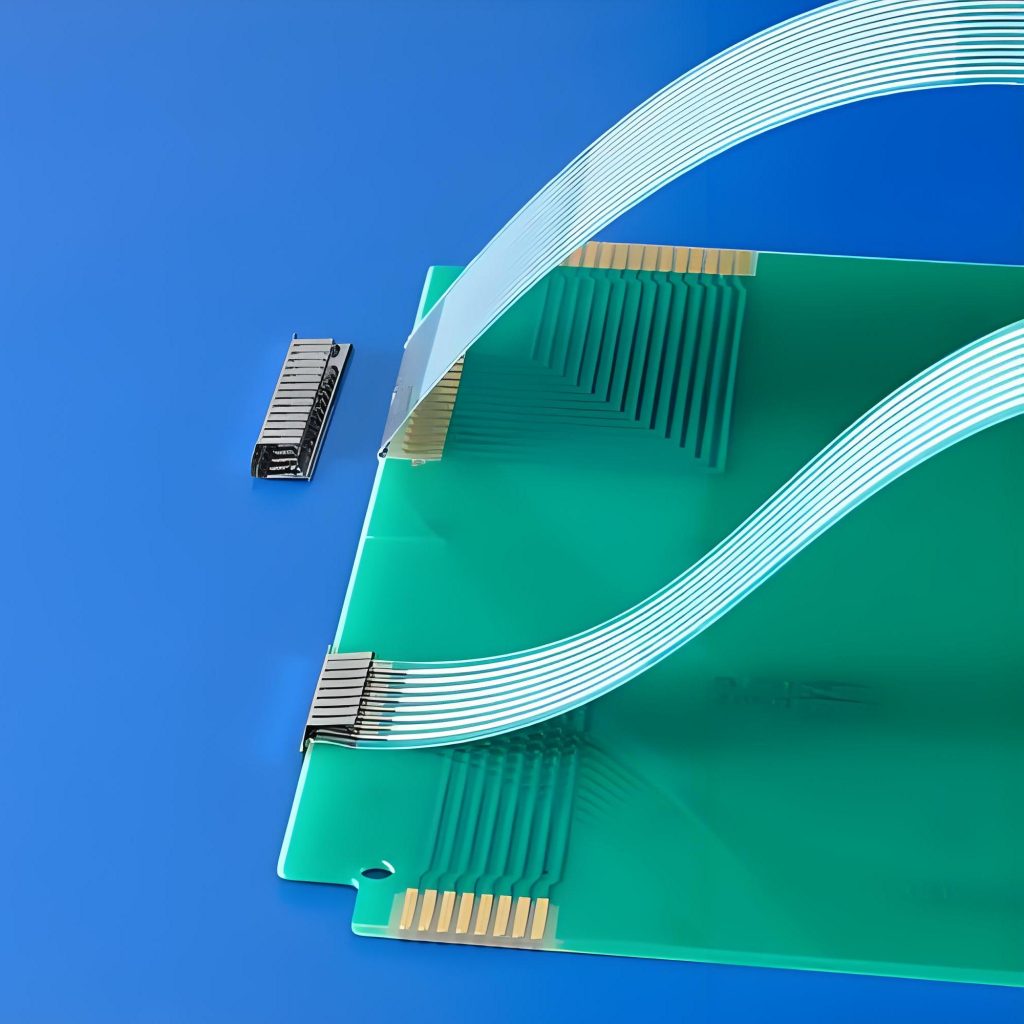

1. By connection method

- Piercing connector: The terminal can pierce the conductive layer of the membrane switch to achieve connection. The connection is simple and fast, and is suitable for large-scale production.

- Welding connector: It is connected to the conductive line of the membrane switch by welding, with high reliability, and is suitable for occasions with high requirements for connection stability.

- Crimp connector: Use mechanical pressure to press the terminal to the conductive layer, fast installation, suitable for scenes with restrictions on welding.

2. By structure

- Strip connector: Long strip shape, multiple contact points, small space occupation, high connection density, suitable for equipment with limited space.

- Circular connector: The contact points are distributed in a circular shape, with good sealing and shock resistance, suitable for occasions with high environmental requirements or vibration.

- Flake connector: Thin sheet shape, thin thickness, can fit tightly with membrane switches, suitable for electronic products with strict thickness requirements.

3. By applicable circuit type

- FFC connector: Used to connect FFC cables and membrane switches, with soft and bendable characteristics, adapt to complex wiring environments, and achieve high-density connections.

- FPC connector: Connects FPC and membrane switches, with high reliability and stability, can withstand bending and tensile stress, and is suitable for equipment that needs to be bent or moved frequently.

The membrane switch connector is an indispensable connection element in electronic equipment. It has the characteristics of light, thin, flexible, high reliability, easy installation, etc., which can meet the needs of different application scenarios. When selecting a membrane switch connector, key points such as electrical performance, mechanical performance, and environmental resistance need to be considered to ensure the reliability and stability of the connection.

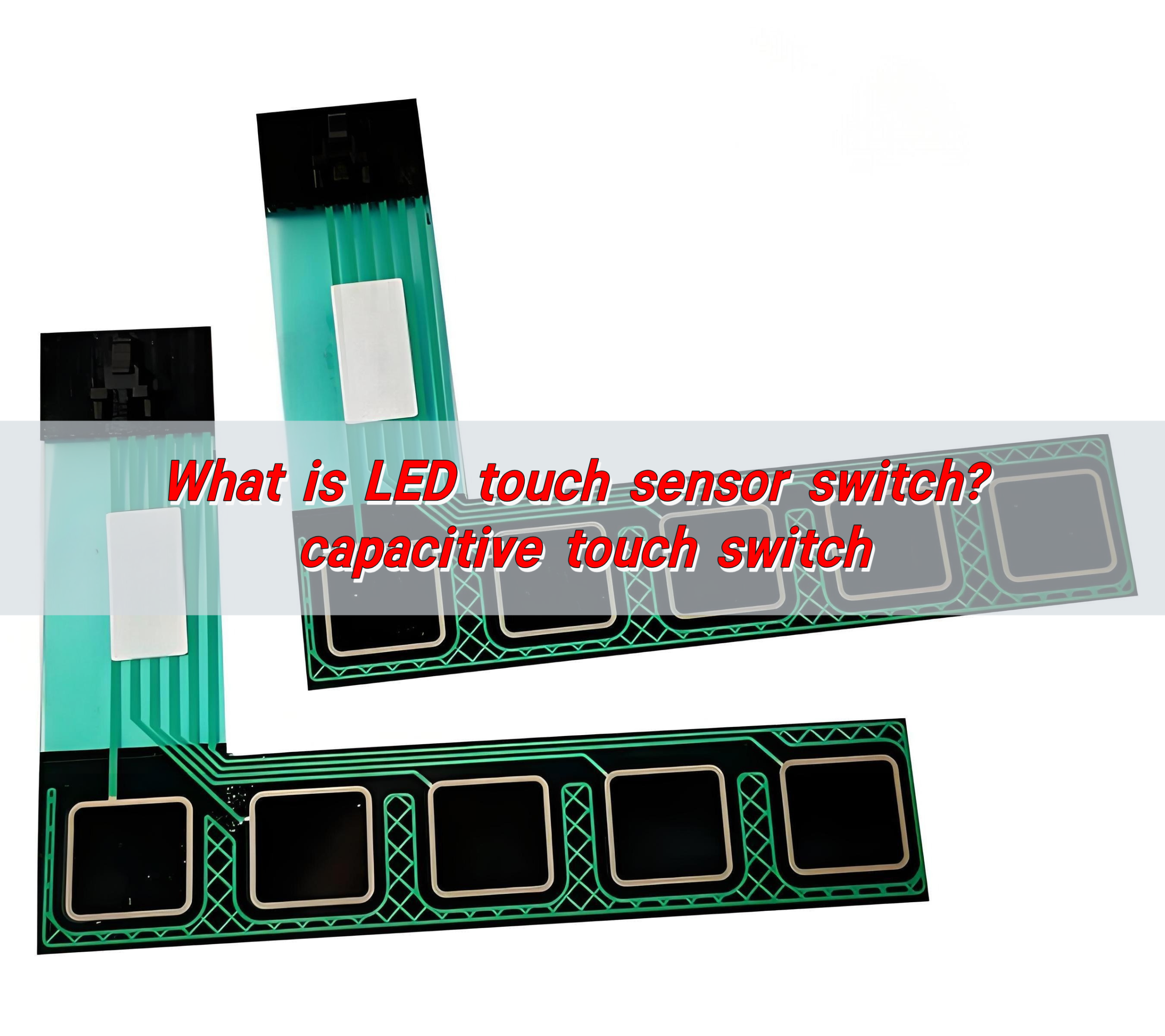

What is LED touch sensor switch? capacitive touch switch

The LED touch sensor switch is an electronic component that combines an LED light and a touch sensor. It controls the on and off of the LED light by touching it, achieving energy-saving and convenient lighting control. It uses capacitive sensing technology to detect human proximity or touch, thereby controlling the on and off of ...

What is IP66 Waterproof? Waterproof Rating of Membrane Switches

The IP66 waterproof rating means that the device is completely protected from dust ingress and can withstand strong water jets. The waterproof rating of membrane switches can usually reach IP67, which is achieved through special processes and materials to ensure its reliability in humid or rainy environments. This performance makes membrane switches suitable for scenes ...

Why are flexible membrane switches a popular choice in modern electronics?

Flexible membrane switches are popular in modern electronic products due to their flexibility, thinness and economy. They not only adapt to complex curved surfaces and achieve flexible design, but also have environmental adaptability such as waterproof and dustproof. In addition, they support multi-function integration, such as LED indicators and sound feedback, to enhance user experience. ...

Contact us online