Membrane Switch Durability

Membrane Switch Durability

A membrane switch gives a visually pleasing human-machine interface that is easy to use, low profile, and electronically stable. They are well known to stand up to harsh conditions. Flex circuitry is resilient and can be used in many different environments. Once you know what the end use will be for the flex circuit, the appropriate overlay material can be selected for the part.

Polycarbonate and polyester are the two most used materials for membrane switches. The overlay starts out as a clear material and then is printed on the back side. This protects the graphics and increases durability.

Adhesive Layers

A membrane keypad is made of about 6 layers and each layer serves a unique function. The Graphic Overlay is on top and provides the actual interface buttons and controls. It is mounted to the rest of the keypad with pressure sensitive adhesive.

The PSA (adhesive) forms a strong body when pressure is applied. It doesn’t need any heat or other solvents to activate. This is also sometimes called cold laminating.

These adhesives will give a certain amount of sealing properties to the rest of the membrane switch. Small amounts of liquid and dust are kept out of the switch by the membrane construction. However, this durability is not good enough for severe settings.

The membrane switch may have problems if dropped into water or other liquids and is submerged for any length of time. The edges of a keypad, which protect the circuitry for most normal day to day operation environments, will be insufficient to keep water out if submerged.

Other Contaminants

- Certain abrasive and corroding cleaners may degrade the quality of an Overlay over time.

- Dust can be a problem with outdoor use.

- High humidity.

- Very high or low temperatures.

- High altitudes.

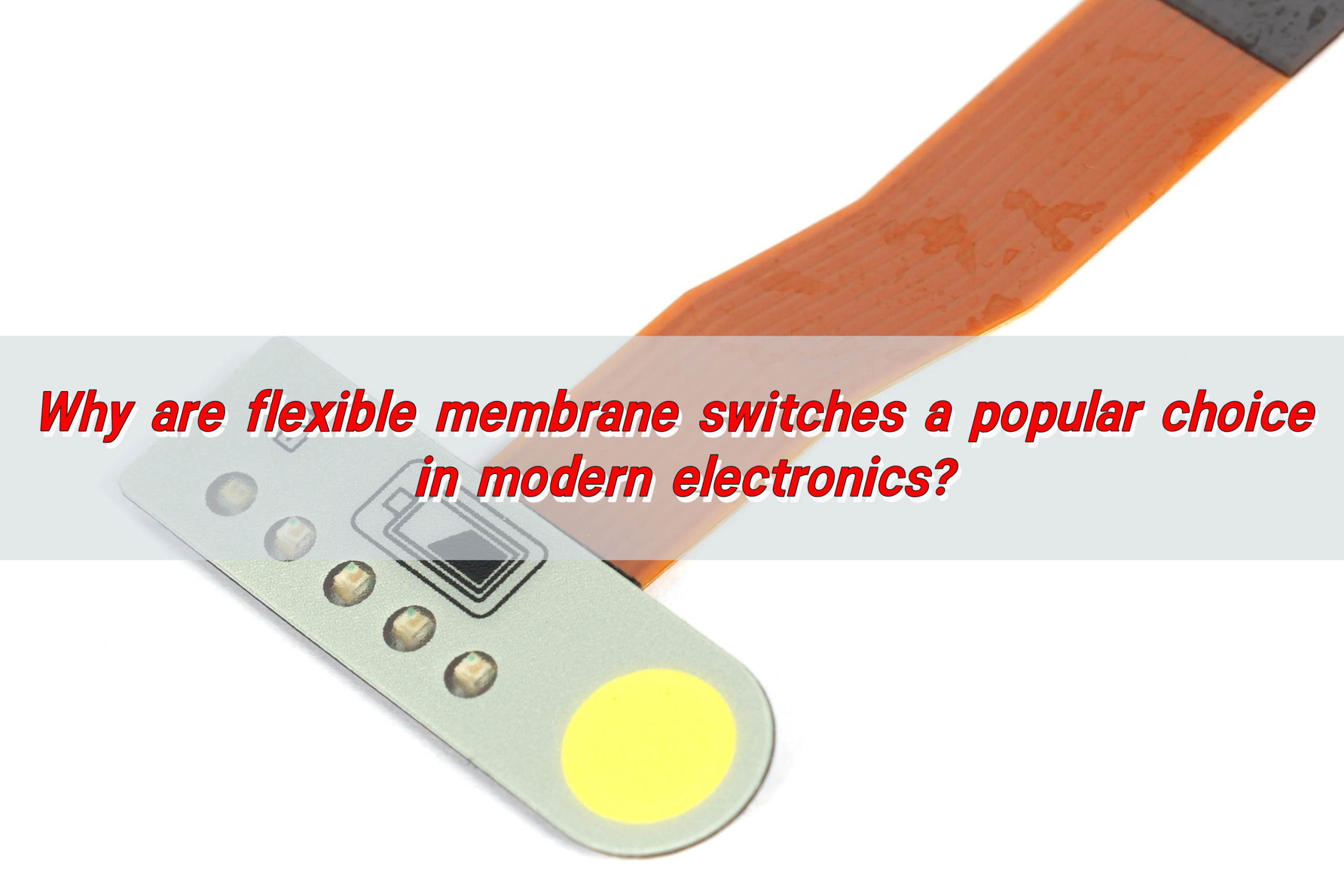

Why are flexible membrane switches a popular choice in modern electronics?

Flexible membrane switches are popular in modern electronic products due to their flexibility, thinness and economy. They not only adapt to complex curved surfaces and achieve flexible design, but also have environmental adaptability such as waterproof and dustproof. In addition, they support multi-function integration, such as LED indicators and sound feedback, to enhance user experience. ...

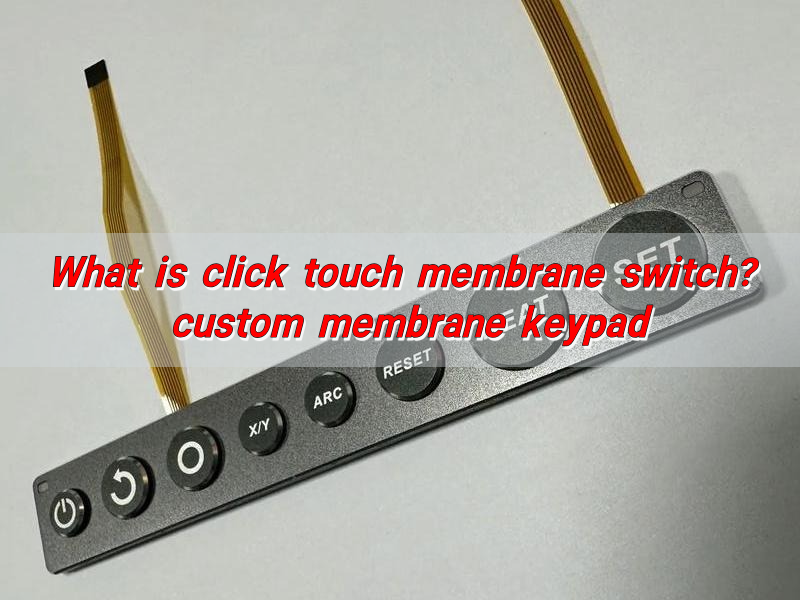

What is click touch membrane switch? custom membrane keypad

Click touch membrane switches are membrane switches that conduct circuits by pressing, have tactile feedback and stable operation, and are widely used in electronic communications, industrial control, medical equipment and other fields. Customized membrane keypad are based on this technology and can choose different materials and layouts according to customer needs. They are both functional ...

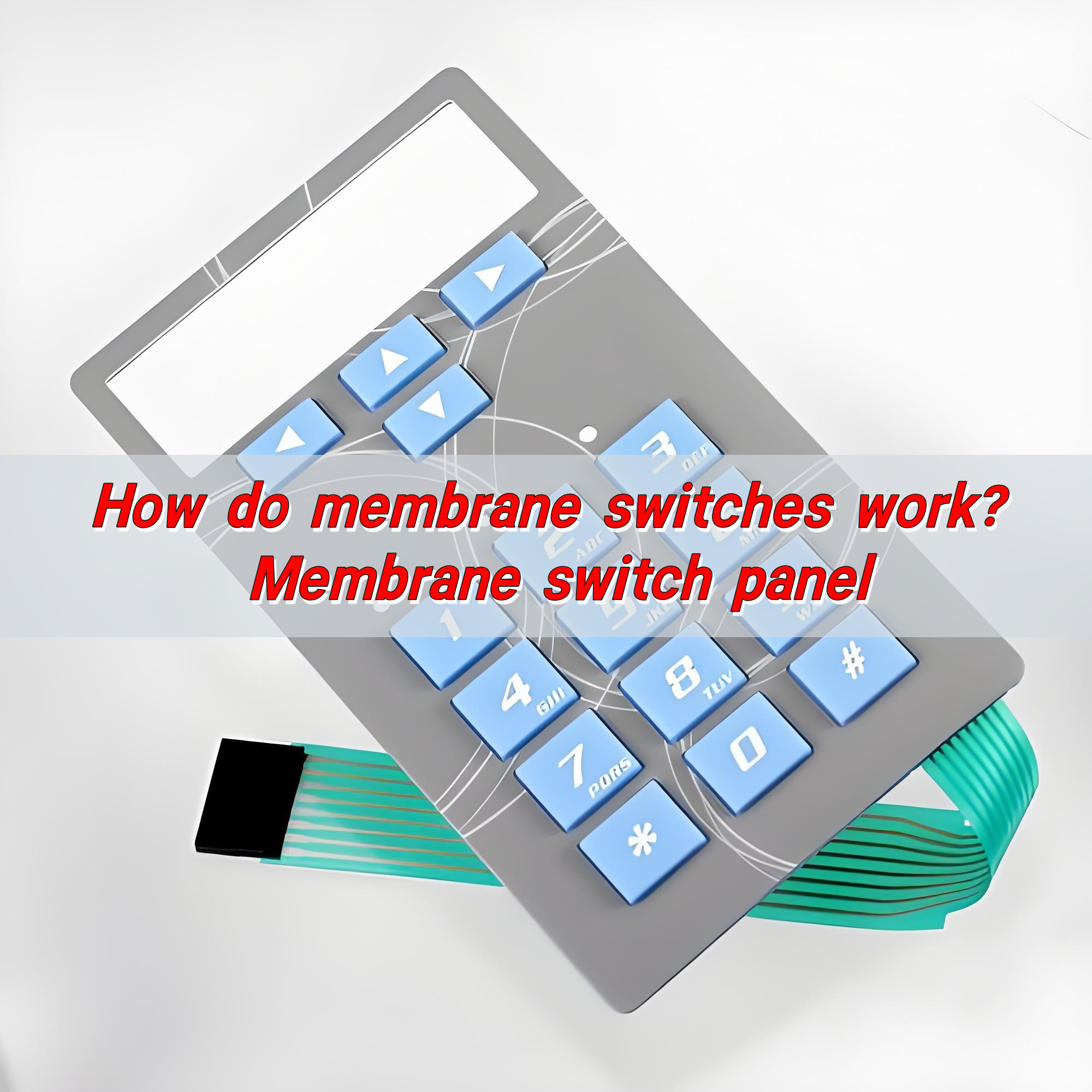

How do membrane switches work? Understanding membrane switch panel

Membrane switch is a new type of electronic component that integrates key functions, indicator elements, and instrument panels. When pressed, the upper circuit contact contacts the lower circuit; when released, the contact rebounds, the circuit is disconnected, and the signal is triggered. Membrane switches have good waterproof and dustproof advantages and are widely used in ...

Contact us online