Silicone Keypad Manufacturers: All About Silicone Buttons

Silicone Keypad Manufacturers: All About Silicone Buttons

Silicone keypad is a keypad made of silicone rubber material, which is soft, elastic and durable. It has good waterproof, dustproof and chemical corrosion resistance, suitable for use in harsh environments.

Yu An Electronics specializes in the production of silicone keypads, which have excellent insulation and circuit conduction properties. During the molding process, the silicone keypad is implanted with conductive particles, and the silicone keypad also has circuit conduction properties.

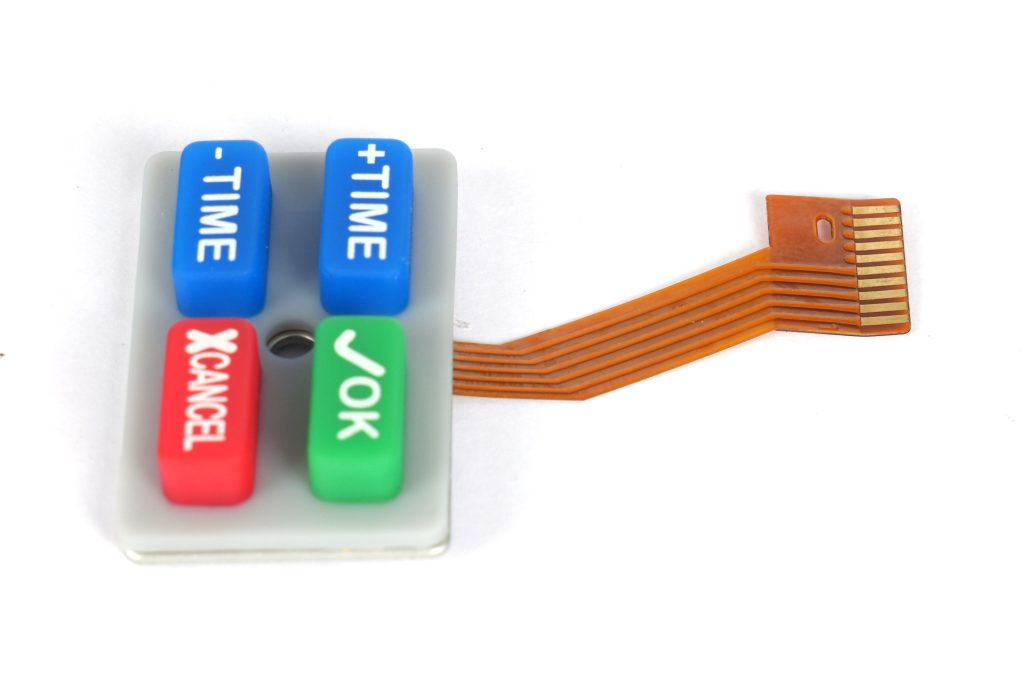

What are silicone keypads?

Silicone keypads, also known as rubber keypads, are flexible and responsive buttons made from silicone rubber. These keypads convert mechanical pressure into electrical signals. When you press a key, it completes a circuit on the underlying printed circuit board. That’s how the device knows which button you’ve pushed.

Unlike plastic buttons, silicone buttons offer a soft, tactile feel. They’re quieter, more resilient to wear, and can be molded into almost any shape or color. A custom silicone keypad can include backlighting, logos, different textures, or even waterproof sealing. This makes them perfect for industries where both function and appearance matter.

Whether you’re using a remote control at home or operating industrial equipment in harsh environments, there’s a good chance a silicone keypad manufacturer had a hand in it.

What are the main materials for making silicone rubber keypads?

The core material, of course, is silicone rubber. This flexible, heat-resistant, and weatherproof material is ideal for keypads. It can endure extreme temperatures, heavy use, and exposure to moisture or chemicals.

But silicone alone doesn’t complete the picture. To function as a button that sends a signal, the keypad needs conductive material. This is often a carbon pill or conductive ink placed under each key. When pressed, it connects the circuit below.

Other essential materials include:

- Pigments to create custom colors.

- Hardness modifiers to control how soft or firm each button feels.

- Protective coatings that add resistance to wear and chemicals.

- Backlight-friendly additives, used when creating illuminated keypads.

An experienced silicone rubber products manufacturer knows how to blend these elements perfectly. The right formula delivers long-lasting, high-performance keypads that won’t wear down quickly.

How to quickly design a silicone button?

Designing a silicone button doesn’t need to be complicated, especially when you work with a trusted keypad manufacturer. Here’s how the process flows:

- Define dimensions. Size, shape, and thickness are all customizable. You can even add embossed or recessed symbols.

- Choose tactile feel. Decide on force resistance. Do you want a soft press or something with a snap?

- Select color and finish. Silicone can be any shade. You can use matte, glossy, or textured finishes.

- Think about features. Will it be backlit? Waterproof? Require custom printing?

- Once the design is clear, a prototype can be made. With modern silicone technology, samples can be produced quickly, tested, and refined before moving to mass production.

Fast turnaround, expert guidance, and strong communication from the silicone keypad manufacturer are key to hitting your project goals.

How to make a silicone rubber keypad?

The silicone keypad manufacturing process is both a science and an art. Precision matters at every stage. Here’s a simplified look at how these buttons come to life:

Molding. Silicone rubber is injected into a steel mold shaped like the final keypad. This mold is custom-made for each project.

- Curing. The mold is heated to cure the silicone, locking in its shape and properties.

- Trimming. Once removed from the mold, excess material (called flash) is trimmed away.

- Printing. Symbols or letters are added using pad printing or laser etching.

- Conductive placement. A small carbon or gold pill is inserted into the base of each button.

- Coating. A protective finish is applied to increase resistance and durability.

- Testing. Each keypad is tested for electrical function, pressure response, and visual defects.

Reliable silicone keypad manufacturer will also conduct aging, chemical, and weather-resistance tests to ensure long-term performance. High-quality production doesn’t cut corners. Instead, it ensures each custom silicone button works perfectly from day one.

What are the advantages of silicone keypads?

The list is long—and for good reason. Because they offer clear advantages:

- Customizable: Shape, color, texture, and print can be easily customized.

- Cost-effective: Once the mold is made, mass production is affordable.

- Durable: Resistant to moisture, heat, chemicals, and UV light.

- Tactile: Provides a satisfying, soft feel and optional tactile response.

- Quiet: Minimal noise during use, unlike mechanical switches.

- Flexible: Easily sealed for waterproof or dustproof applications.

- Versatile: Suitable for medical, industrial, consumer, and military use.

The versatility alone makes these keypads a favorite. If you need reliability and flexibility, few options perform like a well-designed rubber keypad.

What are the disadvantages of silicone keypads?

While benefits are many, it’s fair to acknowledge some limitations. Even the best products have trade-offs:

- Mold cost: The upfront cost of creating a custom mold can be high, especially for small runs.

- Wear and tear: Low-quality keypads may wear out with heavy use.

- Limited travel: Compared to mechanical switches, the travel distance of each press may feel shorter.

However, most of these downsides can be avoided by choosing a skilled silicone keypad manufacturer. With expert design and top-grade materials, performance and lifespan can be optimized.

How to clean silicone buttons?

Keeping silicone buttons clean is simple. Their resistance to water and chemicals makes maintenance easy.

- For regular cleaning: Wipe with a damp microfiber cloth. Use mild soap if there’s sticky residue.

- For deeper cleaning: Use isopropyl alcohol for disinfecting. Avoid sharp tools or abrasive scrubbers.

In rugged environments, custom silicone keypads are often sealed. That means they can be hosed off or cleaned with disinfectants without risk.

Clean buttons not only look better—they last longer. They also reduce the risk of dust or oil disrupting the circuitry underneath.

Where are silicone keypads used?

The applications are almost endless. From everyday devices to highly specialized equipment, silicone keypads are everywhere.

You’ll find them in:

- Remote controls for TVs, stereos, and smart homes.

- Medical devices, where clean surfaces and sealed buttons are essential.

- Industrial machines, exposed to oil, dust, and heat.

- Automotive systems, especially dashboard controls.

- Military equipment, needing durability and reliability in harsh conditions.

- Consumer electronics, like calculators, games, and fitness trackers.

- Telecommunication devices, such as landline phones and routers.

No matter the setting, the right custom silicone keypad offers performance and comfort that standard buttons can’t match.

Conclusion:

Silicone keypads are more than simple buttons—they’re a perfect mix of form, function, and durability. The right silicone keypad manufacturer understands how to design and produce high-quality components that work in tough environments and everyday gadgets alike.

To bring your next project to life with trusted silicone solutions, reach out to us at sales@best-membraneswitch.com

What is a polyurethane coating? Silicone Rubber Membrane Switch

Polyurethane coating is a protective coating with properties such as moisture resistance, chemical resistance, dielectric properties and wear resistance, and is widely used to protect electronic products from environmental influences. In silicone rubber membrane switches, polyurethane coating ensures the stability and reliability of the switch in harsh environments by providing moisture resistance, chemical resistance and ...

Mistakes to Avoid When You Order PCB Membrane Switches

It is a fantastic strategy to ensure the inventory when you run a business that needs membrane switches and pcb units. The priority should be to choose a reliable seller from the competitive industry. There are some errors that you should avoid. Here is a glimpse. Rushing through the order process There is no need ...

Do Membrane Keycaps Exist? Custom Membrane Keycaps

Membrane keycaps are an important part of membrane keyboards. They are usually fixed to the keyboard base by snaps or screws and can be replaced. Custom membrane keycaps can be selected from different materials, colors and patterns according to personal preferences, providing users with a way to personalize their keyboards. Are there keycaps for membrane ...

Contact us online