Quality Control

Yu An Electronics employs a multi-faceted approach and strict adherence to industry standards, ensuring exceptional quality, precision, durability, and extended lifecycle for your parts and prototypes.

Pre-production document review

Every order and document submitted on Yu An is reviewed by an engineer before it is sent to production. When the engineer finds a problem in the document, the system will send a notification to the customer’s order list center and email, where the customer can check in time to avoid delays in production.

Raw material support

We are committed to complying with IPC standards in every product we produce. For all products, whether prototypes, small orders or mass production, you can track the status of production online and our sales assistants update production photos every week.

Advanced equipment

In order to ensure the best quality and reliability of our products, Yu An constantly invests in advanced equipment

Yu An Electronics invests in state-of-the-art production equipment, enabling precise and consistent manufacturing processes. This technology not only enhances the quality of our membrane switches but also increases production efficiency.

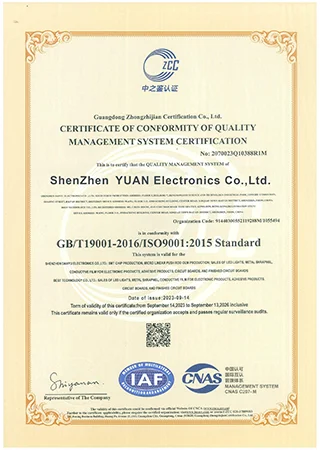

IS0 9001:2015

IS0 14001

REACH

RoHS

Yu An Electronics aims to deliver exceptional prototypes and parts that fulfill your specific requirements. In the event that your order fails to meet your specifications, we can process a rework or a refund. Feel free to contact our experts if you come across any quality issues within 1 month of receiving your goods. Let us know of the issue within five business days from receipt, and we’ll address them within 1 to 3 business days.

Contact us online