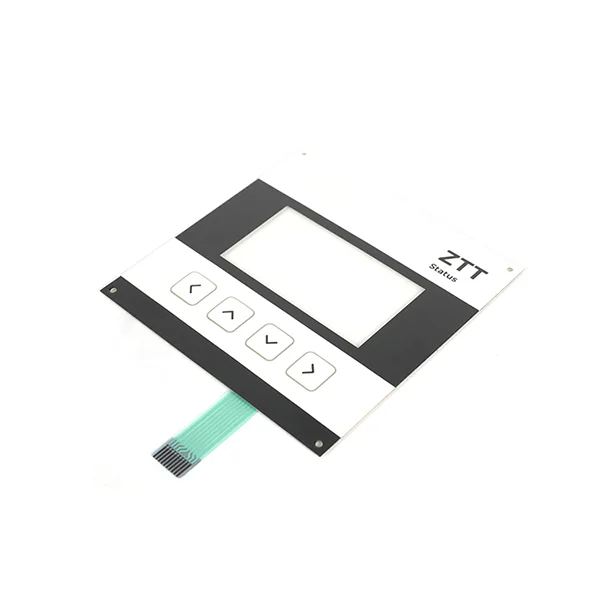

Epoxy Membrane Switch in PET Remote Controls

The epoxy layer on these membrane switches provides a strong protective barrier, making them resistant to scratches, moisture and abrasion, which is especially important when the device may be subjected to rough handling or exposed to varying environmental conditions. This durability ensures the longevity of the PET remote control, increasing its reliability in everyday use.

-

Electrical characteristics:35V (DC), 100mA, 1W

-

Contact resistance:10Ω-500Ω (varies according to the lead wire and the material use, generally<200Ω)

-

Insulation impedance:≥ 100MΩ 100V

-

Dielectric strength:250V Rms (50-60HZ, 1min)

-

Contact jitter time:≤ 5ms

| Basic Parameters of Tactile Membrane Switch | |

| Max. Panel size | 600*800mm |

| Max. Panel size (with emboss) | 400*500mm |

| Paste | silver paste, carbon paste |

| Ink color | red, black, blue, white, yellow, green, purple, etc |

| Trace width | 0.15-0.20mm |

| LED spec. | 0402, 0603, 0805, 1210 |

| Wire length | Per customer requirements |

| Waterproof class | IP65 |

| Connector | female pin, male pin |

| Metal dome types | triangle, for-legs, circle |

| Trip force (metal dome) | 280g, 340g, 450g |

| Travel (metal dome) | 0.35-0.71 |

| Diameter (metal dome) | 8.4mm, 10mm, 12.2mm |

| Surface treatment (metal dome) | gold plating, nickle plating, stainless |

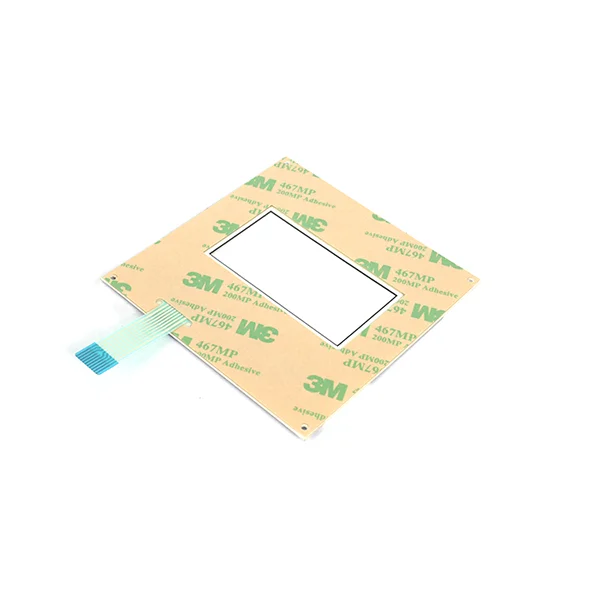

| Back adhesive | DSMS, 3M, SOKEN |

| Citcuit board option | FPC, PCB, Aluminum |

| Panel material | PET, PC, TPU, PMMA |

Epoxy membrane switches find valuable application in scenarios where designers seek a small emboss on the top layer of metal domes for easy identification. This is typically achieved through a process that elevates the key area using magnesium membrane switch overlay embossing dies. Alternatively, epoxy keys offer a practical solution, especially in situations where space constraints make embossing challenging. One of the most important advantages of epoxy keys is their ability to address adhesion issues when keys are closely positioned or near the edge of a component. This ensures sufficient adhesion around the keys, minimizing the risk of delamination. Thus, epoxy keyboards prove to be a versatile and reliable choice in various design scenarios.

Membrane switches have established themselves as a reliable technology for keypad interfaces, possess many advantages that adopting various applications over the years. Here are some key features and design considerations of it.

- Membrane switches are thin and flexible, making well to slightly curved surfaces.

- The design of membrane switches can combine seamlessly with various overlay materials, including PC, PET, or silicone keypads. PC and PET offer options for gloss or textured finishes, with PET demonstrating better life cycle and chemical resistance. Both materials can be enhanced with hard coating for anti-scratch properties.

- Depending on the application, materials with UV resistance for outdoor use or antimicrobial protection for medical environments are available. Customers can choose the most suitable materials for their specific usage environment by consulting with our engineers.

- Backlighting and/or indicator lighting can be incorporated into the circuit layer using LEDs or Light Guide Films (LGF). The overlay can be crafted with a various appearance what you want.

- Key buttons can be embossed, debossed, or perimeter embossed for enhanced aesthetics. Braille emboss dots can be added, and UV-cured epoxy drip buttons provide a 3-dimensional effect through an automated drip process or a UV-imprint method.

- Buttons can be tactile or non-tactile, with choices such as metal domes, polydomes, or dome emboss for tactile buttons. Metal domes with a center opening for LED applications are also available.

- The flex cable connector can take various forms, including female connectors, no connectors with just carbon overprint for ZIF connectors, male pins, or solder tabs.

Contact us online