LED Membrane Switch in Professional Photography Equipment

LED membrane switches, combining the flexibility of printed circuits with the illuminating properties of LED lights, find versatile applications in various components of professional photography equipment, offering a range of benefits that cater to the unique needs of photographers and imaging professionals.

-

Panel material:PC, PET, TPU, PMMA

-

Insulation resistance:>=100VDC

-

Rebound time:<=6ms

-

Loop resistance:≤80Ω (within 40cm of a single key return route)

-

Reliable life cycle:>100times

-

Storage temperature:-40C ~ +85C

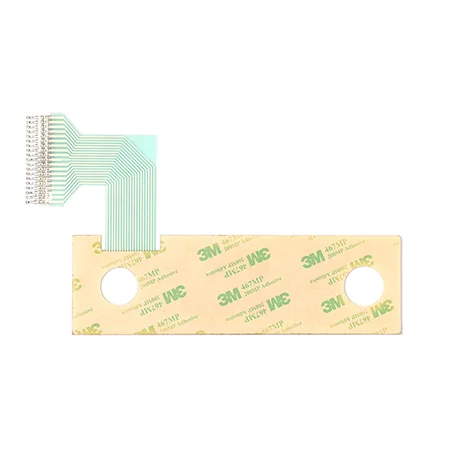

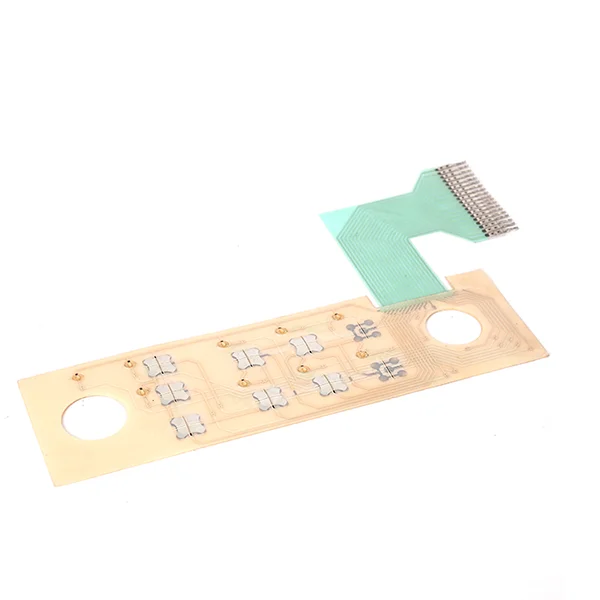

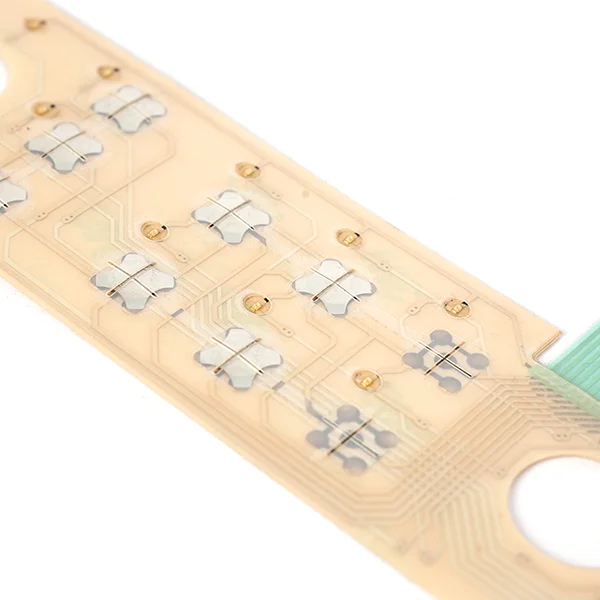

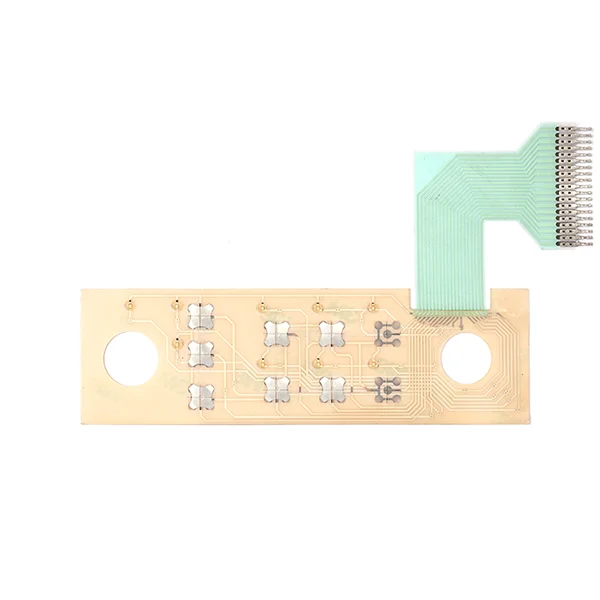

| LED Membrane Switch Specification | |

| Panel size | 50mm*58.6mm |

| Metal dome | 7*10mm (four-legs) |

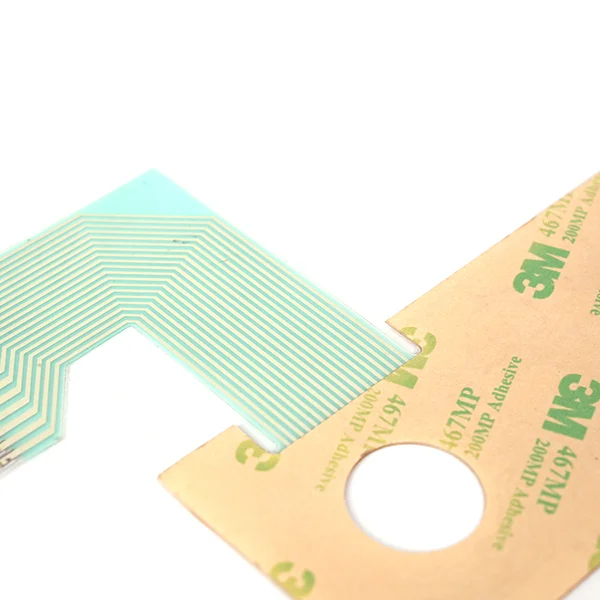

| Overlay spacer | 0.13mm (3M468) |

| Dome carrier | 0.1mm (PET100) |

| Dome spacer | 3M467 |

| Lower circuit | 0.125mm (PET125) |

| Back adhesive | 0.05mm 3M467 |

| LED | RGBW red LED |

| Wire length | 10mm |

| Waterproof class | IP65 |

| Connector | 1*10ways male housing |

| Total thickness | 1.2mm |

The materials used for the graphic overlay exhibit a relatively high dielectric strength and volume resistivity. In cases where enhanced electrical shielding is required, the construction of a membrane switch can incorporate a higher degree of shielding. The specific requirements for shielding can vary significantly depending on the industry for which the product is designed. Shields can be designed to address the following:

- ESD (Electrostatic Discharge)

- EMI (Electromagnetic Interface)

- RFI (Radio Frequency Interface)

To introduce an additional shield beneath the graphic layer of the switch, conductive inks or metalized materials, such as aluminum-clad polyester, can be utilized. Grounding can be achieved through either a separate tail or by utilizing the same connector as the circuitry. Alternatively, a grounding tab can be created for connection to a metal backing plate or support panel.

Client Profile:

CaptureTech Imaging Solutions, a leading innovator in professional photography equipment, collaborated with Yu An Electronics to elevate the user interface of their high-end cameras. They aimed to provide photographers with a sophisticated and customizable control system that could withstand the demands of various shooting environments.

Project Challenges:

CaptureTech faced challenges related to creating a user-friendly and customizable control interface for their cameras. The need for water resistance, quick response times, and durability in varying climates were key considerations for this project.

Our Solutions:

By understanding the clear demands of customers, Yu An Electronics recommended to apply LED membrane switches in their professional cameras. The LED switches, designed for water resistance, rapid response, and durability, successfully addressed the challenges posed by outdoor photography environments. The result was a tailored and reliable control interface that met the stringent requirements of professional photographers.

Customer’s Feedback:

Since this is a prototype order, Yu An Electronics finished it for 1week and deliver them out immediately. After receiving and testing the Light Guide Film membrane switch, CaptureTech found it fully meet all the light demands of the devices, or even make it out of expectation. They are very appreciated the customizable controls, water-resistant design, and the switches’ ability to withstand the rigors of professional photography. This case is the first time that our LED product applied into photograph industry, and it marked a successful milestone both in our and Capturetech’s company.

Contact us online