How to Design a Membrane Switch According to Your Needs

How to Design a Membrane Switch According to Your Needs

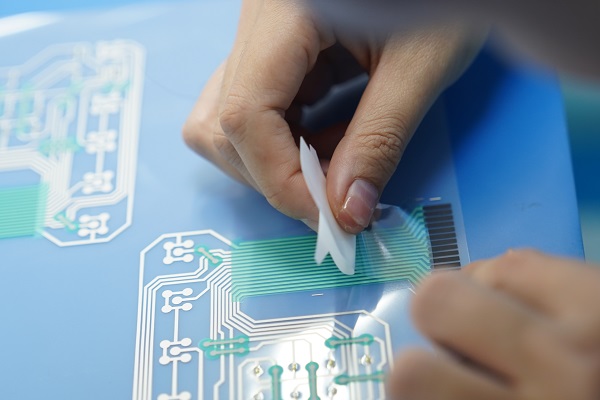

As an integrated control system that integrates key functions, indicating components, and instrument panels, membrane switches are beautiful, lightweight, and have excellent conductive properties. Membrane switches have the characteristics of waterproof, dustproof, and anti-static interference during use. It is widely used in electronic communications, medical equipment, industrial control, instrumentation, automotive industry and smart home. The following is a brief introduction to the membrane switch production process.

Membrane switch design

The membrane switch has a clear structure, mainly including five structural layers: panel layer, surface adhesive layer, upper circuit, interlayer (isolation layer), lower circuit and back adhesive. The thickness of each structural layer can be designed according to the customer’s specific needs, and the thickness of the membrane switch panel can also be increased by adding interlayers.

- The panel layer generally uses high-toughness PET or PC light-transmitting colorless sheets. Different patterns can be printed on the panel layer through digital printing technology. Its main function is to function as logos and buttons;

- The surface glue uses 3M glue to tightly adhere the panel to the upper circuit. 3M glue has super strong adhesion effect;

- Both the upper circuit and the lower circuit are made of polyester film (PET) with excellent toughness, screen-printed with conductive silver paste and conductive carbon paste, and dried and aged to make it conductive. For circuit outlets with a plug-in spacing of less than 1mm, the golden finger connection socket is very convenient. It is easy to puncture the silver paste and cause defects. It is recommended to use FPC with strong wear resistance for the entire circuit;

- The interlayer plays the role of insulation and bonding between the upper circuit and the lower circuit;

- For the bottom layer of adhesive, first consider what kind of material it is attached to, and choose a 3M adhesive that can adhere closely to the adhesive surface.

All material selections for membrane switches must take into account the overall sealing, waterproofness, insulation and aging resistance. For membrane switches used outdoors, additional considerations need to be taken into consideration such as wind and rain, seasonal temperature changes, and strong ultraviolet radiation in the sun. envirnmental factor. When designing membrane switches as a whole, engineering designers must take both science and technology into consideration to ensure that the products produced are both stable, reliable, economical and practical.

Why choose a PET membrane switch? Key benefits you should know

PET membrane switches have good key life, corrosion resistance, wear resistance, and excellent insulation performance, and are suitable for key parts that are used frequently. They have high hardness and can withstand large key forces, ensuring long-term stability. In addition, PET membrane switches have good temperature resistance and can operate in a temperature range of ...

What is a PCB Membrane Switch? PCB Switch Types

PCB membrane switch is a switch based on rigid circuit board, suitable for application scenarios that require stronger mechanical stability and reliability. It is usually composed of multiple layers of film, including conductive film, circuit breaker film and display film, etc., and the circuit is turned on and off by touch or press operation. The ...

What is LGF Membrane Switch? Backlit Membrane Switch

LGF membrane switch is a membrane switch that uses light guide film technology, which can achieve uniform light emission and good visual effects. LGF membrane switches are usually composed of multiple layers of film, including conductive film, circuit breaker film and display film, etc., and the circuit is turned on and off by touch or ...

Contact us online