How much do membrane switches weigh?

How much do membrane switches weigh?

The panel layer, isolation layer and adhesive layer of membrane switches are usually made of materials such as polyester film. Its weight depends on the material selection, size and number of buttons. In terms of materials, different polyester films, conductive materials and metal shrapnel will affect the weight due to their characteristics; the larger the size, the more materials are required, and the weight increases accordingly; the more buttons there are, the more materials are needed for each button and the connecting part, which will also increase the weight.

What material is a membrane switch made of?

The main materials of membrane switches include polycarbonate (PC), polyvinyl chloride (PVC), polyester (PET) and polyethylene (PE).

- 1. Polycarbonate (PC): PC material film has high temperature resistance (-30℃~130℃), high elasticity, high impact resistance and good processing adaptability. It can maintain stable performance when the temperature changes, and is suitable for various occasions such as sign film panels.

- 2. Polyvinyl chloride (PVC): PVC material film is cheap, has good chemical corrosion resistance and insulation performance, but poor temperature resistance, generally softens at around 60℃, and is suitable for use under general conditions.

- 3. Polyester (PET): PET film has good switch life, corrosion resistance and wear resistance, excellent insulation performance, and is suitable for instruments and home appliance panels with high requirements.

- 4. Polyethylene (PE): PE film has good physical and chemical properties and can withstand a variety of chemicals, but the price is relatively high.

Material selection and application scenarios

- 1. PC material: Due to its high temperature resistance and good mechanical properties, PC material is widely used in various sign film panels. It is moderately priced and is the most commonly used material.

- 2. PVC material: Although it has poor temperature resistance, it is cheap and suitable for use under general conditions.

- 3. PET material: Due to its excellent corrosion resistance and wear resistance, it is suitable for instruments and home appliance panels with high requirements.

How much do membrane switches weigh?

The weight of membrane switches generally ranges from a few grams to dozens of grams, and the thickness is generally around 1mm, which is very easy to carry and disassemble.

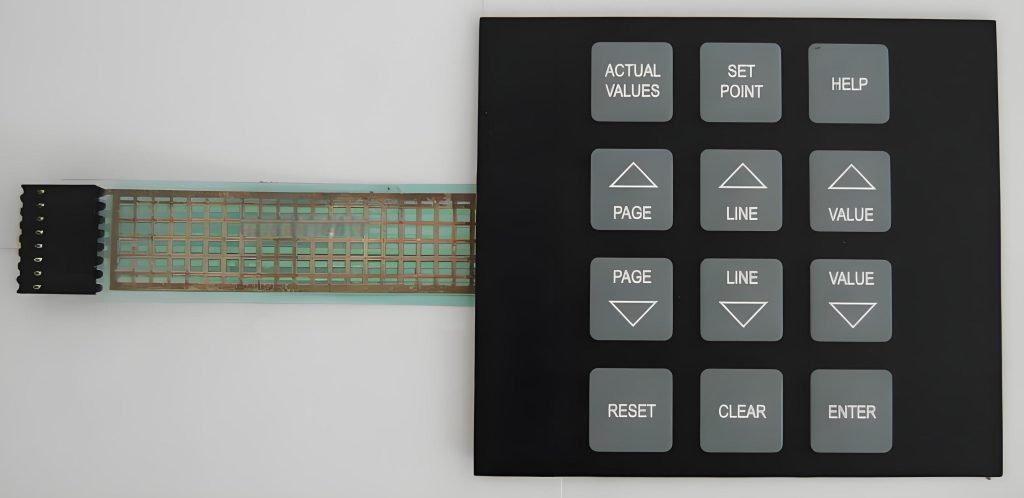

Material and structure of membrane switches

- Panel layer: Usually made of colorless and light-transmitting sheets such as PET and PC, with exquisite patterns and text printed on them.

- Glue pad layer: used to connect the panel layer and the circuit layer tightly, the thickness is generally between 0.02 and 0.05mm, with high viscosity and anti-aging properties.

- Control circuit upper and lower layers: polyester film (PET) is used as a carrier, and silver paste, carbon paste or gold paste is screen-printed to achieve conductive properties.

- Interlayer: located between the upper circuit and the lower circuit layer, it plays a sealing and connecting role, and generally uses PET double-sided adhesive.

- Back adhesive layer: according to the material selection of the paste, common ones are ordinary double-sided adhesive, 3M adhesive, waterproof adhesive, etc.

The selection and design of these materials make the membrane switch light, beautiful, sealed, and conductive, and suitable for various electronic devices.

Are membrane switches good?

The membrane switch has many advantages, which makes it perform well in many fields and is considered to be a good electronic component.

First of all, the appearance design of the membrane switch is flexible and beautiful. It can be made into various colors, patterns and fonts according to needs to meet the appearance design requirements of different products, making the product more visually attractive and unique.

In addition, membrane switches come in a variety of shapes and sizes, and can adapt to the shape and size requirements of different devices. Whether it is a small electronic product or a large industrial equipment, you can find a suitable membrane switch.

Secondly, the operation of the membrane switch feels comfortable and the feedback is clear. Its buttons are usually designed with a certain elasticity and travel, with moderate pressing force, comfortable operation feel, and a good operating experience for users.

When the button is pressed, there will be obvious tactile feedback, which reduces the possibility of misoperation, which is especially important for some devices with high requirements for operation accuracy.

The functional reliability of the membrane switch is high and the service life is long. Using high-quality materials and advanced manufacturing processes, it has high mechanical strength and wear resistance, long service life, and can generally reach hundreds of thousands or even millions of operations.

In addition, the membrane switch has good waterproof, dustproof, moisture-proof, corrosion-resistant and other properties, and can work normally under various harsh environmental conditions.

The membrane switch is small in size and light in weight, and will not add too much volume and weight burden to the equipment, which is conducive to the miniaturization and lightweight design of the product. Its structure is simple and can be directly pasted or installed on the surface of the equipment to save space.

Membrane switches are widely used in household appliances, office equipment, instrumentation, electromechanical products, industrial control, toys and other complete products.

Due to its good waterproof, dustproof, oil-proof, and harmful gas erosion resistance, membrane switches are also widely used in electronic communications, electronic measuring instruments, industrial control, medical equipment, automotive industry and other fields.

In summary, membrane switches are widely used in many fields and perform well due to their flexible appearance design, comfortable operation feel, strong functional reliability, small size and light weight.

How long do membrane switches last?

The service life of a membrane switch is generally more than three years, and the specific time will be affected by many factors.

- 1. Use environment: If the use environment is good and there is no excessive external impact, high temperature, high humidity and other adverse factors, the service life of the membrane switch may be longer, or even longer.

- 2. Frequency of use: The service life of a membrane switch is closely related to its frequency of use. Frequent use will increase the wear of the switch, thereby shortening its service life.

- 3. Material quality: High-quality materials and reasonable structural design can significantly extend the service life of a membrane switch. For example, metal dome-type membrane switches may have a longer service life due to their better feel and stability.

Maintenance and maintenance recommendations

- 1. Avoid high temperature and high humidity environments: Try to avoid placing membrane switches in high temperature and high humidity environments to reduce material aging and corrosion.

- 2. Gentle operation: During use, try to avoid strong pressing or impact to reduce mechanical wear.

- 3. Regular inspection: Regularly check the working status of the membrane switch, and promptly discover and deal with potential problems to extend its service life.

Why are membrane keyboards cheaper?

The main reasons for the lower price of membrane keyboards include their low manufacturing cost, simple production process, and market demand and positioning.

First, the manufacturing cost of membrane keyboards is relatively low. The structure of membrane keyboards is relatively simple, and it mainly uses a layer of membrane as a key trigger device. This design reduces the complexity of production materials and processes, thereby reducing manufacturing costs.

In contrast, mechanical keyboards use independent mechanical switches as the trigger device for each key. These switches contain complex mechanical structures, and the manufacturing materials and processes are relatively complex, resulting in relatively high costs.

Second, the simplification of the production process is also one of the reasons for the lower price of membrane keyboards. The production process of membrane keyboards is relatively simple and does not require complex mechanical processing and assembly, which makes its production efficiency higher and further reduces costs.

In addition, market demand and positioning also affect the price of membrane keyboards. Membrane keyboards are more popular with general users due to their price advantage.

In summary, the low price of membrane keyboards is mainly due to the combined effect of factors such as low manufacturing cost, simple production process, market demand and positioning.

What is the disadvantage of membrane keyboard?

The main disadvantages of membrane switches include short life, poor anti-interference performance, high cost and insufficient sensitivity. Specifically:

- Short life: Due to its fragile internal structure, membrane switches are frequently subjected to mechanical pressure when used in high-frequency human-machine interface devices, resulting in a short service life.

- Poor anti-interference performance: The circuit board of a membrane switch can often only provide simple and traditional interference suppression measures. When subjected to external electromagnetic interference, it is easy to cause problems such as misoperation.

- High cost: The production cost of membrane switches is relatively high, and it often requires a lot of human and material resources to be invested in the production process.

- Insufficient sensitivity: Compared with mechanical switches, membrane switches are not sensitive enough during use, and sometimes a larger key force may be required to trigger the operation.

In short, the weight of the membrane switch is an important factor to consider. By selecting thin and light materials, optimizing the design and adopting reasonable manufacturing processes, the weight of the membrane switch can be effectively reduced to meet the requirements of modern electronic devices for thinness. At the same time, as an important component of the membrane switch, the metal dome also has an important impact on its weight and performance.

Top Membrane Switches for Home Electronics Projects in 2025

You can elevate your home electronic membrane switch project in 2025 with standout models such as the 4×4 Matrix 12 Keys Keypad from SOUSHINE, the rgb-enabled strip switches from Molex, and custom graphic switches by Panasonic. These switches offer slim profiles and reliable performance, making them easy to integrate into your DIY setup. You gain ...

Top tips for fixing PS4 controller conductive film keypads

Are you frustrated because your PS4 controller buttons have stopped working? You are not alone. Many gamers experience issues with the conductive film keypad for ps4. Button failures often happen because of dirt, debris, or rough handling. Take a look at the most common causes: Cause Description Dirt and debris Accumulation in button crevices can ...

Top Membrane Switch Companies Leading the Industry in 2025

You see a dynamic market shaping the future of membrane switch technology. Leading companies like Molex, SOUSHINE, YU AN Electronics, TE Connectivity, Honeywell, Omron, Mitsubishi Electric, Panasonic, Industrial Print Technologies, SCHURTER, XYMOX, Douglas Corp, Dyna-Graphics, ELO Touchscreens, UTC, LUNFENG Technology, and Fujikura drive growth with innovation and global reach. Choosing the right membrane switch company ...

Contact us online