How Do You Classify Metal Dome Button in the Electronic Devices?

How Do You Classify Metal Dome Button in the Electronic Devices?

Metal dome buttons play a crucial role in modern electronic devices by offering tactile feedback, reliability, and long-lasting performance. They are commonly found in membrane switches, keypads, and control panels used across various industries such as consumer electronics, automotive, medical devices, and industrial equipment. To better understand their functionality and applications, it’s important to classify metal dome buttons based on different criteria such as shape, actuation force, size, material, structure, and application.

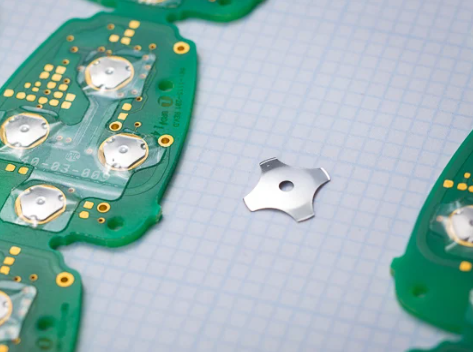

Classification by Shape

The shape of a metal dome button affects its tactile response, actuation force, and overall performance in an electronic device. Manufacturers produce different shapes to suit various design needs and applications. The most common shapes include:

- Four-Legged Domes

Four-legged domes are one of the most commonly used designs due to their even distribution of force and balanced tactile feedback. Their symmetrical shape allows them to provide reliable actuation and stability, making them ideal for applications such as remote controls and medical devices.

- Round Domes

Round domes are widely used for their consistent and smooth tactile feel. They provide uniform actuation force across their surface and are preferred in applications where precision and reliability are important, such as consumer electronics and automotive interfaces.

- Triangular Domes

Triangular domes are designed for compact layouts where space is limited. Their shape allows for firm actuation while maintaining a smaller footprint, making them suitable for handheld devices and portable medical equipment.

- Oblong Domes

Oblong domes are elongated, providing a larger contact area and more flexibility in terms of actuation points. They are often used in applications where multiple points of contact may be required, such as industrial control panels and specialized keypads.

Classification by Actuation Force

The actuation force of a metal dome button determines how much pressure is required to trigger it. This factor directly affects the usability and tactile feedback experienced by the end user. Metal domes are classified into the following categories based on their actuation force:

- Low Force (80–180g)

Low-force domes require minimal effort to press, providing a soft and responsive feel. They are commonly found in applications where ease of use is a priority, such as remote controls, handheld devices, and medical equipment that require quick, effortless operation.

- Medium Force (200–300g)

Medium-force domes offer a balanced tactile response and durability. These are widely used in consumer electronics, including keyboards and gaming controllers, where users expect a firm yet comfortable press.

- High Force (350g and above)

High-force domes are designed for industrial and automotive applications where accidental activation needs to be avoided. They provide a robust tactile response, making them suitable for rugged environments that require enhanced durability and precision.

Classification by Size

Metal dome buttons come in various sizes to meet the specific requirements of different applications. The size impacts the tactile response, actuation force, and overall design flexibility of the device.

- Small Domes (4mm–8mm)

Small metal domes are ideal for compact devices such as mobile phones, smartwatches, and other portable electronics where space constraints are critical. Despite their small size, they provide reliable tactile feedback.

- Medium Domes (9mm–14mm)

These domes strike a balance between size and functionality, making them a popular choice for applications like remote controls, industrial equipment, and membrane keypads.

- Large Domes (15mm–20mm)

Large domes are used in applications requiring greater tactile response and visibility, such as automotive dashboards, control panels, and heavy-duty machinery interfaces.

Classification by Material

The material of a metal dome button affects its conductivity, corrosion resistance, and durability. Different materials are chosen based on the operating environment and performance requirements.

- Stainless Steel Domes

Stainless steel is one of the most common materials used for metal domes due to its excellent corrosion resistance, strength, and durability. It is suitable for high-use applications in industrial, automotive, and medical devices.

- Nickel-Plated Domes

Nickel plating enhances conductivity and wear resistance, making these domes an excellent choice for applications that require high electrical performance and longevity, such as consumer electronics and automotive controls.

- Gold-Plated Domes

Gold-plated domes provide superior conductivity and resistance to oxidation, making them ideal for high-end applications that require precise and long-lasting performance, such as aerospace and medical equipment.

Classification by Structure

The internal structure of a metal dome significantly influences its tactile feedback, longevity, and reliability. Depending on the application, different structural designs can be used to achieve specific performance characteristics.

- Dimple Domes

Dimple domes feature a small indentation in the center that enhances their tactile response and provides a distinct “snap” feel when pressed. This structure is widely used in applications requiring a clear tactile response, such as industrial control panels.

- Flat Domes

Flat domes have a smooth, even surface without any central dimple. They provide a softer actuation and are typically used in applications where a gentle press is preferred, such as touch-sensitive panels in consumer electronics.

- Vented Domes

Vented domes include tiny perforations that allow air to escape, reducing the chance of air entrapment and improving their overall tactile consistency. They are commonly used in environments where long-term reliability is crucial, such as medical devices and automotive applications.

- Non-Vented Domes

These domes do not have perforations, which helps to prevent dust and moisture ingress. They are often used in outdoor or rugged applications where environmental protection is required.

Classification by Application

Metal dome buttons are used in a wide range of industries, each with its own set of requirements and expectations for tactile feedback, durability, and responsiveness.

- Consumer Electronics

Metal domes are extensively used in consumer electronics such as smartphones, remote controls, and gaming devices. They offer a responsive tactile feel and long lifespan, ensuring a satisfying user experience.

- Medical Equipment

Precision and reliability are essential in medical devices, and metal dome buttons are commonly used in diagnostic equipment, patient monitoring systems, and handheld medical instruments.

- Industrial Controls

Industrial equipment often requires rugged and durable components. Metal domes used in control panels, automation systems, and manufacturing equipment must withstand harsh environments and heavy usage.

- Automotive Applications

In the automotive industry, metal domes are used in dashboard controls, infotainment systems, and steering wheel buttons. Their durability and consistent performance make them suitable for vehicle interiors exposed to varying temperatures and vibrations.

- Aerospace and Defense

High-end aerospace and defense applications require metal domes that can operate in extreme environments while maintaining precise actuation and long-term reliability.

Classifying metal dome buttons based on shape, actuation force, size, material, structure, and application provides valuable insights into selecting the right components for specific electronic devices. Whether it’s a compact medical device requiring light actuation or an industrial control panel demanding high durability.

Metal domes offer a perfect combination of tactile feedback, durability, and precision, making them indispensable in modern electronic design. By choosing the right type of metal dome, manufacturers can enhance the overall functionality and longevity of their products, ensuring a seamless user experience across various industries.

What is LED touch sensor switch? capacitive touch switch

The LED touch sensor switch is an electronic component that combines an LED light and a touch sensor. It controls the on and off of the LED light by touching it, achieving energy-saving and convenient lighting control. It uses capacitive sensing technology to detect human proximity or touch, thereby controlling the on and off of ...

What is IP66 Waterproof? Waterproof Rating of Membrane Switches

The IP66 waterproof rating means that the device is completely protected from dust ingress and can withstand strong water jets. The waterproof rating of membrane switches can usually reach IP67, which is achieved through special processes and materials to ensure its reliability in humid or rainy environments. This performance makes membrane switches suitable for scenes ...

Why are flexible membrane switches a popular choice in modern electronics?

Flexible membrane switches are popular in modern electronic products due to their flexibility, thinness and economy. They not only adapt to complex curved surfaces and achieve flexible design, but also have environmental adaptability such as waterproof and dustproof. In addition, they support multi-function integration, such as LED indicators and sound feedback, to enhance user experience. ...

Contact us online