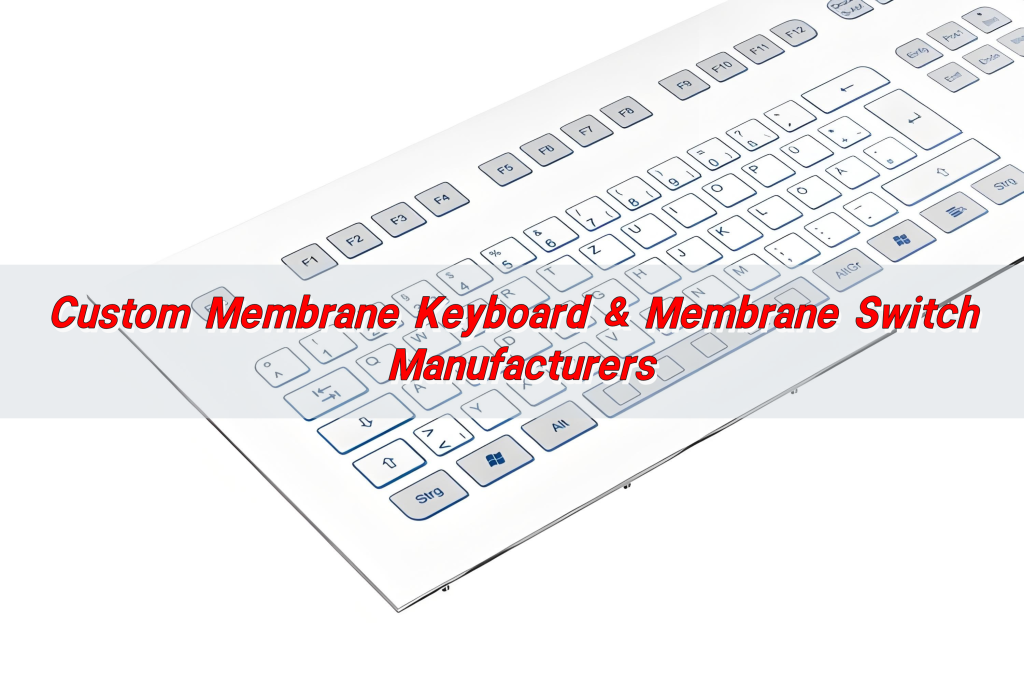

Custom Membrane Keyboard & Membrane Switch Manufacturers

Custom Membrane Keyboard & Membrane Switch Manufacturers

Custom membrane keyboard is an input device that can be designed and produced according to demand, and is widely used in medical, industrial, financial and other fields. It has the characteristics of waterproof, dustproof, durable, etc., and can meet the use requirements in special environments.

The membrane keyboard consists of membrane keys, keyboard PCB decoding control board and output lines, etc. It has a simple structure, low cost, good flexibility and precise electrical connection performance.

What is a membrane keyboard?

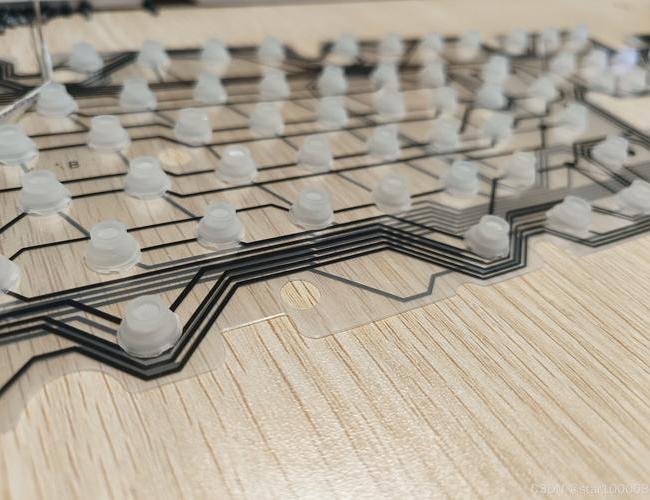

A membrane keyboard is a compact, lightweight input device. It consists of flexible, pressure-sensitive layers instead of mechanical switches. When a key is pressed, it activates an electrical circuit beneath the surface. This design makes it quieter, more durable, and resistant to dust and moisture.

Unlike mechanical keyboards, membrane keyboards use a flat interface. They have fewer moving parts, reducing wear and tear. This makes them a preferred choice for industrial, medical, and consumer electronics. Custom membrane keyboards offer tailored solutions, ensuring optimal performance for specific applications.

How to design a membrane keyboard?

Designing a custom membrane keyboard requires precision. Every element, from material selection to key layout, affects functionality and user experience.

First, define the keyboard’s purpose. Is it for industrial machinery, medical equipment, or gaming? Each application has unique needs. Once the purpose is clear, choose the right materials. Polyester and polycarbonate are common for durability and flexibility.

Next, decide on the circuit design. A custom membrane keyboard can have different layouts, including tactile or non-tactile feedback. Tactile feedback offers a slight resistance, improving accuracy. Adding embossing to the keys enhances responsiveness.

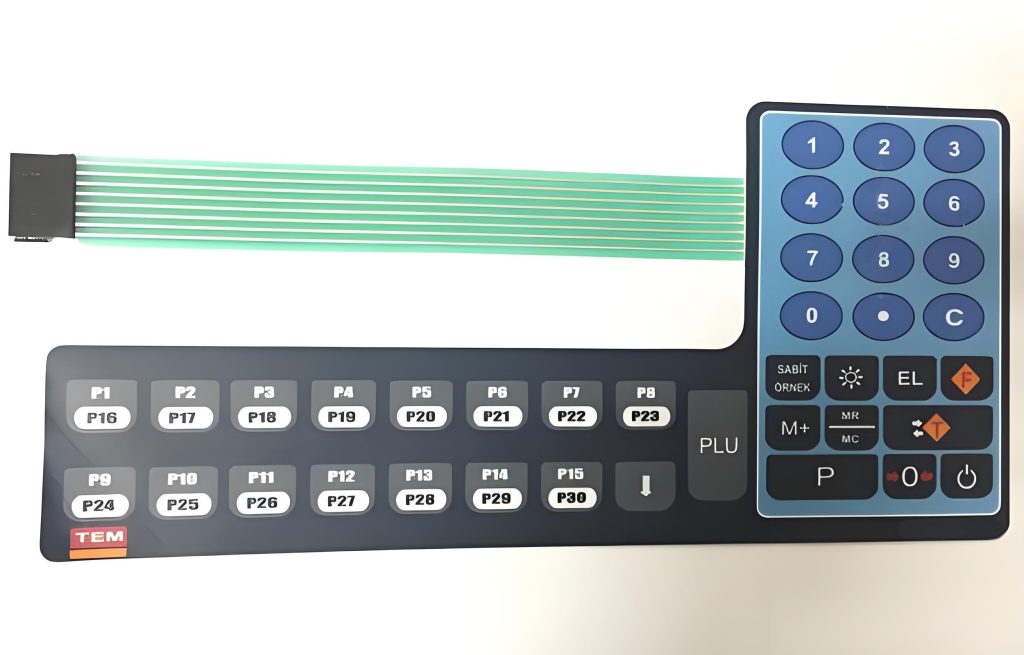

Graphic overlays play a crucial role. They define the appearance and provide a protective layer. Custom printing allows logos, labels, and specific colors to be added. For enhanced usability, backlighting or LED indicators can be integrated.

For user comfort, spacing and key size matter. A well-planned layout improves efficiency, especially in industrial settings. Ergonomic considerations help prevent strain during extended use.

What is the disadvantage of a membrane keyboard?

While custom membrane keyboards offer many advantages, they do have limitations. However, their drawbacks are minimal compared to their benefits.

One key limitation is the lack of tactile feedback compared to mechanical keyboards. Some users prefer the “clicky” sensation of mechanical switches. However, this can be improved with custom membrane keys for improved feedback keyboards.

Durability is another concern in heavy-use environments. Though highly resistant to dust and moisture, membrane keyboards may wear out faster with excessive force. To enhance longevity, high-quality materials should be used.

Another factor is key rollover. Standard membrane keyboards may struggle with multiple simultaneous key presses. However, advanced designs can incorporate anti-ghosting technology, solving this issue.

Despite these challenges, custom membrane keyboards remain a top choice for industries needing reliability, cost efficiency, and flexibility.

How to put custom cover to membrane keyboard?

Custom covers enhance both functionality and aesthetics. They provide protection against spills, dust, and chemicals. They also allow personalization, adding unique branding elements.

To install a cover, first, measure the keyboard precisely. A well-fitted cover ensures smooth operation without interfering with key presses. Many covers are made from silicone or polyurethane, offering flexibility and durability.

For a custom keyboard membrane, adhesive overlays can be applied. These are thin, durable layers printed with custom graphics. They adhere to the keyboard’s surface without affecting responsiveness.

Custom keycaps are another option. Custom keycaps for membrane keyboards allow for improved tactile feel and better visibility. Some overlays come with raised or embossed keys, making navigation easier.

If the keyboard is used in harsh environments, consider a waterproof or antimicrobial cover. These add an extra layer of protection, extending the lifespan of the device.

What are the applications of membrane keyboard?

Membrane keyboards are widely used across different industries due to their adaptability and durability.

- Medical Equipment: Hospitals and laboratories require keyboards that are easy to clean and disinfect. Custom membrane keypads and keyboards ensure hygienic operation.

- Industrial Machinery: Factories and manufacturing units prefer customed membrane switch keyboards for their resistance to dust and chemicals.

- Consumer Electronics: Many household devices, such as remote controls and microwave panels, use customized membrane keyboard keys for smooth operation.

- Military and Aerospace: Rugged environments demand durable input solutions. Membrane keyboard custom designs can withstand extreme conditions.

- Gaming and Office Use: Some gaming and professional setups use custom membrane keyboards for quiet and comfortable typing.

These keyboards are versatile. They can be customized to fit any industry’s needs, ensuring both functionality and reliability.

Membrane Switch Manufacturer

As a membrane switch manufacturer, we specialize in creating high-quality, custom membrane keyboards for diverse applications. With years of expertise, we ensure precision engineering, durable materials, and innovative designs.

We provide tailor-made solutions, from custom membrane keys for improved feedback keyboards to fully personalized layouts. Our manufacturing process follows strict quality standards, guaranteeing reliability and longevity.

Whether you need a medical-grade keyboard, an industrial control panel, or a specialized gaming keypad, we deliver top-tier solutions. Our team is committed to providing durable, efficient, and cost-effective products.

Conclusion:

Custom membrane keyboards offer flexibility, durability, and cost-effectiveness. They are widely used in medical, industrial, and consumer applications. While they have minor drawbacks, their advantages far outweigh them.

For businesses looking for high-quality custom membrane keypads and keyboards, choosing an experienced membrane switch manufacturer ensures the best results. For more information, contact us at sales@best-membraneswitch.com

Tags:

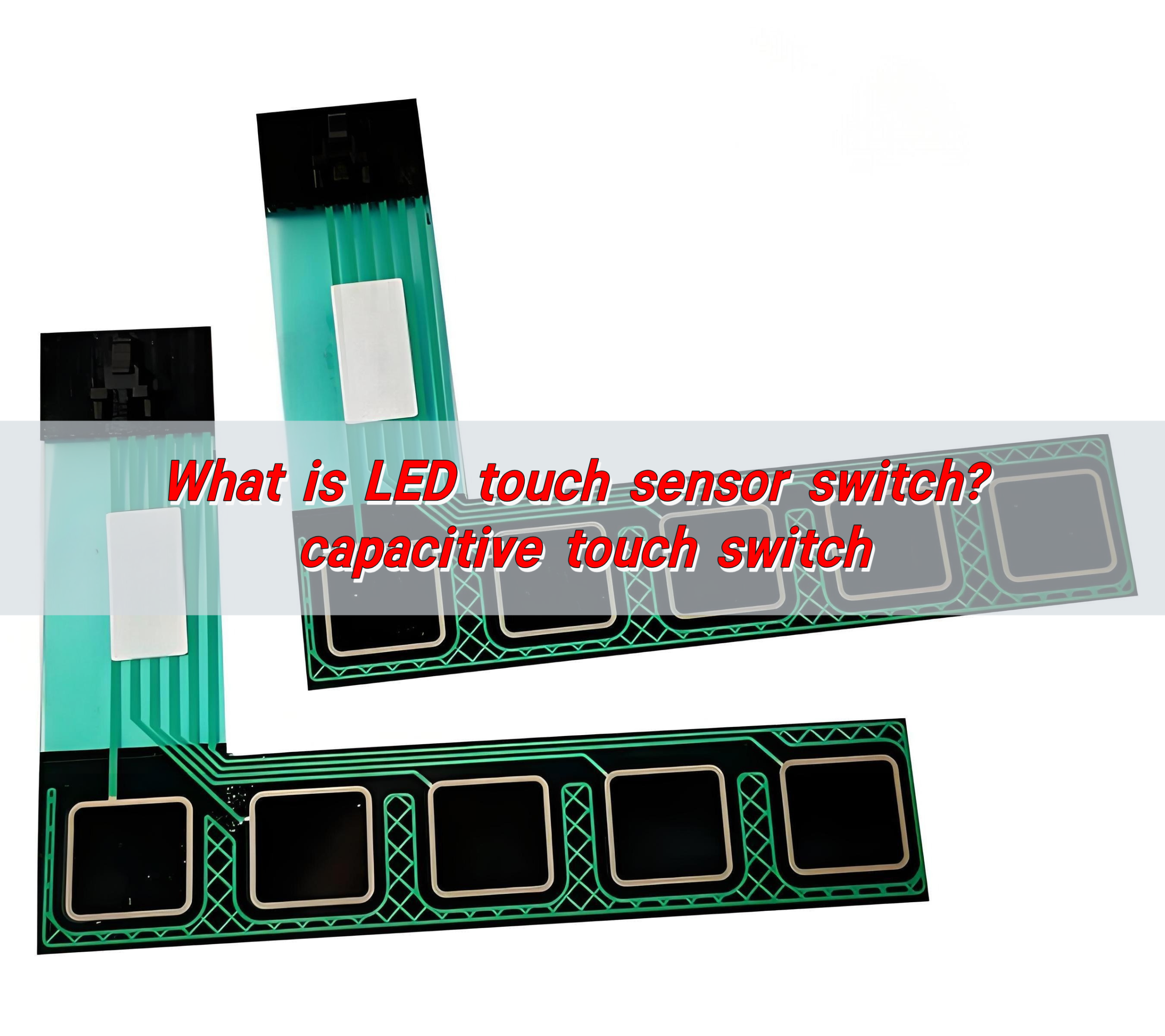

What is LED touch sensor switch? capacitive touch switch

The LED touch sensor switch is an electronic component that combines an LED light and a touch sensor. It controls the on and off of the LED light by touching it, achieving energy-saving and convenient lighting control. It uses capacitive sensing technology to detect human proximity or touch, thereby controlling the on and off of ...

What is IP66 Waterproof? Waterproof Rating of Membrane Switches

The IP66 waterproof rating means that the device is completely protected from dust ingress and can withstand strong water jets. The waterproof rating of membrane switches can usually reach IP67, which is achieved through special processes and materials to ensure its reliability in humid or rainy environments. This performance makes membrane switches suitable for scenes ...

Why are flexible membrane switches a popular choice in modern electronics?

Flexible membrane switches are popular in modern electronic products due to their flexibility, thinness and economy. They not only adapt to complex curved surfaces and achieve flexible design, but also have environmental adaptability such as waterproof and dustproof. In addition, they support multi-function integration, such as LED indicators and sound feedback, to enhance user experience. ...

Contact us online