Are there different types of membrane switches?

Are there different types of membrane switches?

Ordinary membrane switches only have basic key functions. They can switch the circuit on and off by pressing the key. They have a simple structure and low cost, and are suitable for electronic devices with relatively simple functions. Waterproof membrane switches have good waterproof performance and are made of special sealing structure and waterproof materials. They are widely used in outdoor waterproof occasions.

What are the different types of switches in membrane keyboard?

The switch types in membrane keyboards mainly include the following:

- Metal dome type: metal dome is used as the conductive medium, which has the advantages of good key feel, uniform force and high stroke accuracy. A crisp sound can be heard during operation to avoid repeated operation. The disadvantage is that the dome may cause short circuit, malfunction and non-rebound.

- Flat touch type: The contact point uses a film substrate to print the conductor, and no secondary process is used. The advantage is that the key life is long, which can reach one million times, the conductive contact area is large, and the conductivity is guaranteed. The disadvantage is that there is no operating feel, which is easy to cause repeated operation or malfunction.

- Capacitive sensing type: Conductive sensing is used to sense conduction, similar to a capacitive touch screen. The advantage is that it can sense the action within a certain distance, and the sensing distance can be designed according to the customer’s specifications. The disadvantage is that the qualified rate of finished products is low, and the design requirements are very high.

- PCB circuit type: Use PCB circuit board to replace the thin film circuit layer. The advantage is that the PCB circuit is high in precision, the welding of LED is more firm and reliable, and the resistance value is lower. The disadvantage is that PCB is a hard material and cannot be bent.

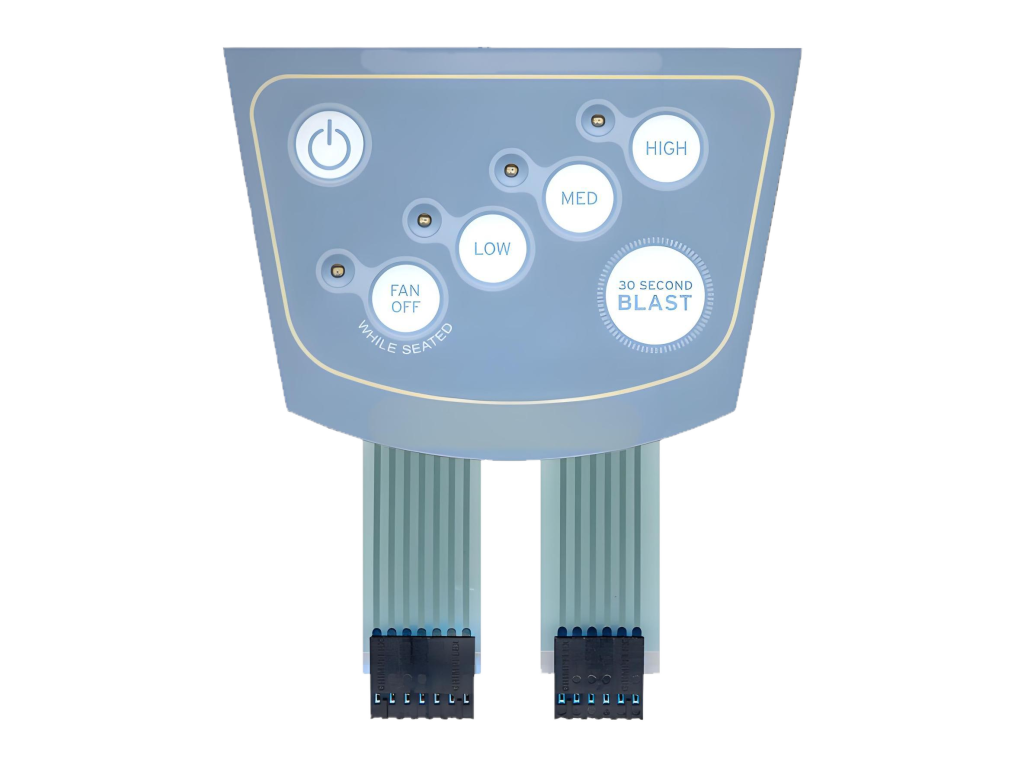

What is an example of a membrane switch?

Examples of membrane switches include home appliances, 3C electronics, automotive control, children’s toys and other fields.

In home appliances, membrane switches are widely used in various home appliances, such as washing machines, refrigerators, air conditioners, etc. Membrane switches are not only used as appearance decoration, but also can realize multiple functions, such as control switches, temperature adjustment, etc.

In 3C electronic products, membrane switches are often used in control panels of devices such as smartphones, tablets, and laptops. They not only provide operating functions, but also enhance the overall texture of the product through their beautiful appearance and durable characteristics.

In automotive control systems, membrane switches are widely used in various automotive electronic equipment, such as audio systems, air conditioning control systems, etc. They can withstand the complex environment inside the car and provide stable and reliable switching functions.

In children’s toys, membrane switches are often used in various interactive toys and electronic toys. Various functions can be achieved through simple operations. They are safe, durable and suitable for children.

Are membrane switches clicky?

When operating, membrane switches may make a clicking sound. This sound is usually caused by the mechanical touch of the key, specifically, due to the poor contact of the dome due to oxidation. When the membrane switch (key button switch, membrane switch) is pressed, the dome will deform. If the surface of the dome is oxidized and the contact is poor, it will cause a clicking sound.

In addition, membrane switches are widely used in industrial environments, including medical, industrial control, automation, rail transportation, aviation and navigation, network communications, consumer electronics, instrumentation, agricultural machinery and equipment manufacturing. In these application scenarios, the operation frequency of membrane switches is high, so the occurrence of clicking sounds may be more frequent.

Are membrane switches good?

Membrane switches have many advantages, which make them widely used in many fields.

The advantages of membrane switches include:

- Waterproof and dustproof: membrane switches have good sealing and can be used in various harsh environments.

- Lightweight and small size: membrane switches are compact in design and easy to carry and install.

- Long life: The service life of membrane switches can generally reach more than one million times, with good heat resistance and folding resistance.

- Beautiful appearance: membrane switches are rich in color and have various pattern designs, which can meet different decoration needs.

- Low price: Compared with other multifunctional electronic products, membrane switches are relatively cheap and suitable for large-scale production and application.

How long do membrane switches last?

The service life of membrane switches is usually more than 1 million times. Specifically, the life of membrane switches can be calibrated to more than 1 million times, and even more than 3 million times in some cases.

The reason for this long life is that the action of the membrane switch is mainly achieved by the slight bounce of the elastic film in the vertical direction. This action mode enables the membrane material to withstand high-frequency use without deformation.

What is the difference between membrane and dome switch?

There are significant differences between membrane switches and dome switches in terms of structure, working principle and application scenarios.

1. Structure and working principle

The membrane switch consists of four parts: panel, upper circuit, isolation layer and lower circuit. When the membrane switch is pressed, the contact of the upper circuit deforms downward and contacts the plate of the lower circuit to conduct. After the finger is released, the contact of the upper circuit rebounds, the circuit is disconnected, and a signal is triggered.

The membrane switch is usually composed of a layer of insulating material with a certain elasticity. The action is realized by the elastic movement of the elastic film in the vertical direction. Although the elastic film has undergone millions of creeping, due to the rationality of material selection, the film material can withstand more than one million times of life without deformation.

Dome switches, especially metal dome switches, use metal dome as the conducting medium. When the switch is pressed, the metal dome deforms to make the circuit conductive; after release, the dome returns to its original state and the circuit is disconnected.

2. Application scenarios

Membrane switches are widely used in various industries, including household appliances, office equipment, industrial control, toys, etc. Its advantages include beautiful appearance, comfortable feel, high reliability, long service life, low cost, small size, light weight, and good waterproof, dustproof and oil-proof properties.

Metal dome switches are widely used in electronic products such as car navigation systems, remote controls, and communication equipment because of their long life, low resistance, stable performance, sensitive response, and uniform force. In addition, metal dome switches are also waterproof, dustproof, and oil-proof.

3. Comparison of advantages and disadvantages

The advantages of membrane switches include:

- Durability: The film material can withstand more than one million times of life without deformation.

- Aesthetics: Beautiful appearance, rich colors, and beautiful appearance.

- Applicability: Suitable for various electronic devices, with good waterproof, dustproof, and oil-proof properties.

Disadvantages include:

- Feel: No operational feel, easy to cause repeated operation or misoperation.

The advantages of metal dome switches include:

- Good feel: Good button feel, uniform force, and high stroke accuracy.

- Durability: Long life, low resistance, and stable performance.

- Sensitive response: Uniform force and sensitive response.

Disadvantages include:

- Environmental adaptability: Use in high temperature environments may cause the button force to weaken.

What is the difference between a tactile switch and a membrane switch?

There are significant differences between tactile switches and membrane switches in terms of function, structure and application scenarios.

1. Function and structure

- Tactile switch: A tactile switch is an electronic switch that switches on and off by changing the force of a metal spring. A tactile switch cannot function independently and must be used in conjunction with a PCB circuit board to form a complete control system.

- Membrane switch: A membrane switch, also known as a touch-sensitive keyboard, uses an overall sealed structure composed of a flat multi-layer combination. It has its own circuits. Usually, the top layer is a panel with text or patterns made of materials such as PET or PC, the bottom layer is a conductive circuit, and the middle layer is a double-sided adhesive made of PET material that simulates the switch form and acts as an isolation.

2. Application scenarios

- Tactile switch: It is widely used in various electronic devices, such as home appliances, instruments and meters, and automation equipment. Due to its small size and simple structure, it is suitable for use in devices with limited space.

- Membrane switch: Due to its flexibility and aesthetics, it is widely used in high-end home appliances, automotive interiors, medical equipment and other fields. Membrane switches can be customized in different sizes, appearances and colors, making them more convenient and flexible to use.

3. Production process

- Tactile switch: The production process includes stamping, injection molding, cleaning, assembly, molding, inspection and other processes.

- Membrane switch: The production process includes silk screen printing, die cutting, assembly, testing and other processes.

In summary, tactile switches and membrane switches have their own characteristics in terms of function, structure and application scenarios. Tactile switches are more suitable for equipment with limited space, while membrane switches are more common in high-end products due to their beauty and flexibility.

In short, membrane switches are available in different types, such as flat, convex, flexible, waterproof, and luminous. Different types of membrane switches have their own characteristics in terms of appearance structure, functional characteristics and application fields. You can choose the appropriate membrane switch type according to specific needs.

How to clean silicone rubber? Silicone Rubber Membrane Switch

How to clean silicone rubber? To clean the silicone rubber membrane switch, use a mild detergent and a soft cloth. First, turn off the power and remove the keycaps. Use a slightly damp soft cloth to gently wipe the switch and surrounding areas to remove dust and stains. If the stains are stubborn, wipe with ...

IP65 vs IP67: What Are the Differences?

IP65 vs IP67? The IP65 protection level provides complete dust protection for the device and can withstand low-pressure water jets from all directions, making it suitable for ordinary outdoor environments. Based on this, IP67 allows the device to be immersed in 1 meter of water for a short period of time (usually 30 minutes) without ...

Mechanical vs Non Mechanical Keyboard: What’s the Difference?

The main differences between mechanical keyboards and non-mechanical keyboards (such as membrane keyboards) are structure, feel, durability and sound. Each key of a mechanical keyboard has an independent switch, providing a clear feel and tactile feedback, strong durability, louder sound, and is suitable for gamers. Non-mechanical keyboard keys contact the circuit board through a rubber ...

Contact us online