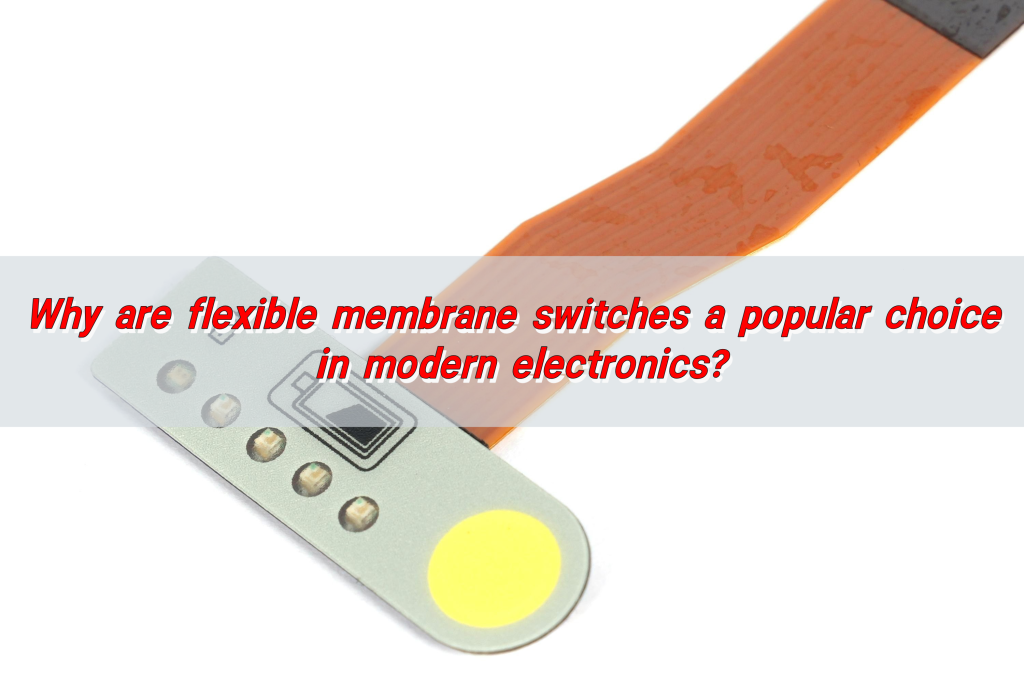

Why are flexible membrane switches a popular choice in modern electronics?

Why are flexible membrane switches a popular choice in modern electronics?

Flexible membrane switches are popular in modern electronic products due to their flexibility, thinness and economy. They not only adapt to complex curved surfaces and achieve flexible design, but also have environmental adaptability such as waterproof and dustproof. In addition, they support multi-function integration, such as LED indicators and sound feedback, to enhance user experience.

What is a flexible membrane switch?

Flexible membrane switch is a low-profile electrical switch that activates with slight pressure. It consists of several thin layers of polyester or polycarbonate, each serving a unique function in delivering tactile or non-tactile feedback.

These switches are engineered to be lightweight, highly adaptable, and resistant to environmental challenges. Unlike traditional mechanical switches, which rely on metal components and bulkier designs, membrane flexible switches offer a smooth, streamlined solution.

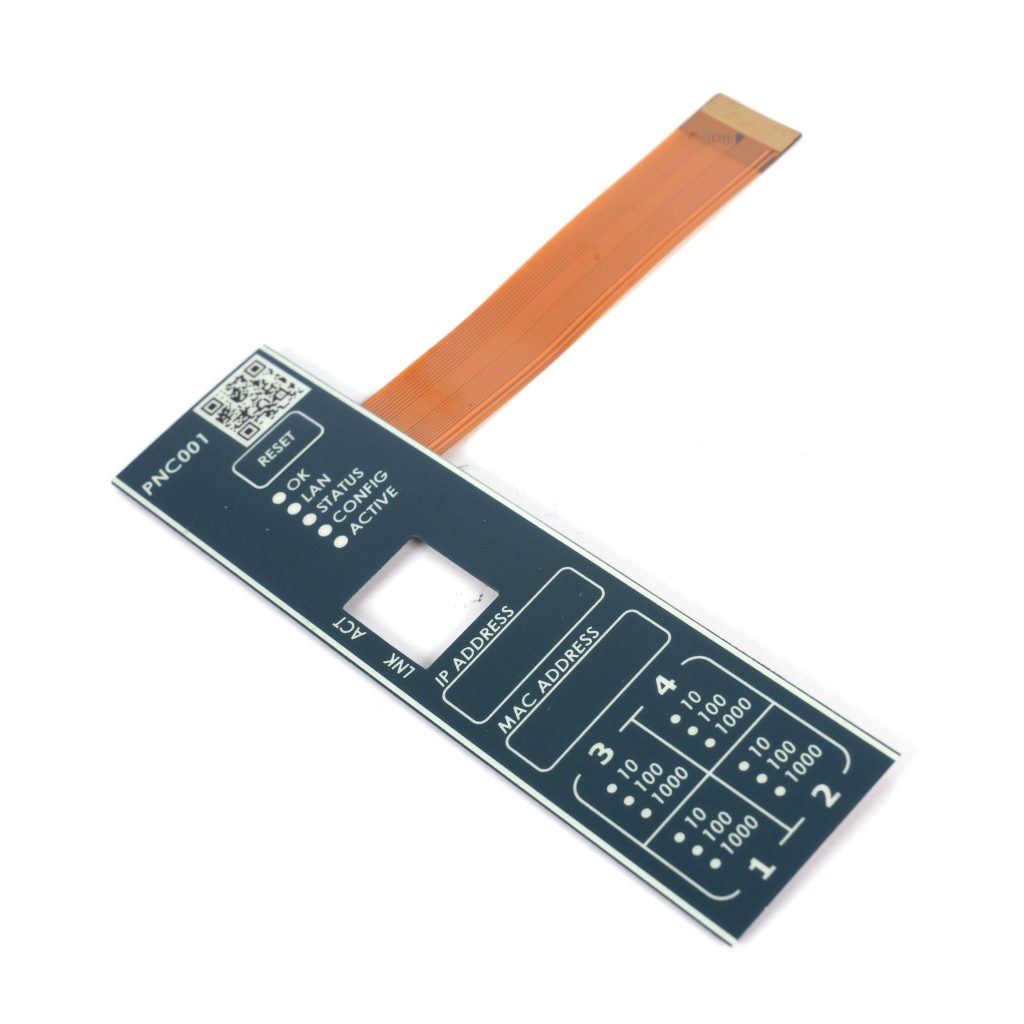

Most commonly, a flexible membrane keypad includes a graphic overlay, adhesive spacers, top and bottom circuits, and a flexible tail that connects to the main device. The design is tailored for simplicity but doesn’t compromise performance.

Whether it’s a medical device, a smart home control panel, or an industrial interface, flexible switches fit in seamlessly—both physically and functionally.

What is the process of manufacturing flexible membrane switches?

First, the layout is carefully planned based on the client’s needs. Whether it requires tactile domes, LED backlighting, or a waterproof seal, everything starts from design.

The manufacturing usually begins with printing conductive inks onto flexible substrates. This step defines the switch’s circuit patterns. Once dried and tested, the different layers are aligned and assembled.

Adhesive spacers are inserted between circuit layers to prevent accidental contact. The graphic overlay, which is what the user interacts with, is added last. It carries all the design elements—icons, labels, and branding.

Finally, a membrane switch connector, typically a flexible tail with embedded conductive traces, is attached. This tail plugs directly into the PCB, making integration easy and efficient.

Quality control is critical here. Each switch goes through rigorous testing to ensure long-term reliability, consistent actuation, and electrical accuracy.

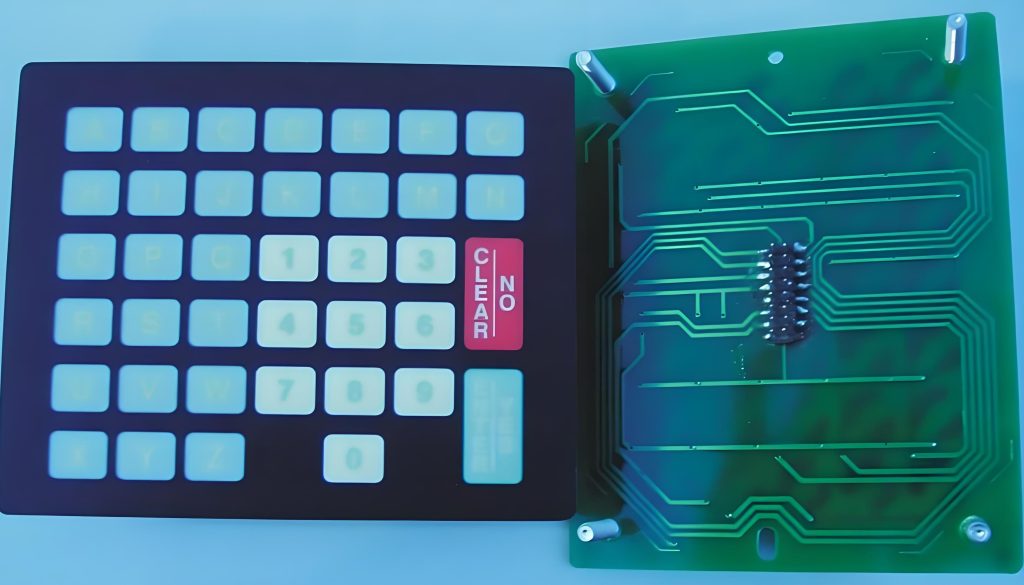

How do flexible membrane switches differ from traditional switches?

While mechanical switches offer physical feedback through springs or levers, membrane switches use pressure to close a circuit. This creates a lighter, quieter actuation with fewer moving parts—resulting in longer lifespans.

Flexible membrane switches are significantly thinner and more adaptable. Their design allows for flat and curved surface applications. Mechanical switches can’t offer that kind of design freedom. They’re bulkier, louder, and often prone to dust and moisture damage.

Flexible membrane switch factories can produce large volumes at a fraction of the cost of traditional switches. They’re ideal for mass-market electronics where reliability and affordability go hand-in-hand.

And for products that require unique layouts or aesthetics, customized flexible membrane switches shine. Designers can tailor every element—from shape and button placement to LED integration and tactile feedback.

What are membrane switch connectors?

Membrane switch connector is the component that links the switch to its main circuit board or controller. Typically, it comes in the form of a flexible tail—often made of polyester—embedded with conductive traces that transmit signals when a button is pressed.

These connectors offer significant benefits. They reduce bulk, simplify assembly, and provide strong signal integrity. More importantly, they’re designed for high flexibility. That’s crucial in tight spaces or devices where movement and bending are part of regular use.

Manufacturers often choose between ZIF (Zero Insertion Force) connectors and crimped leads depending on the device’s complexity and the number of signal lines required.

What are the key features of waterproof flexible membrane switches?

When it comes to durability, waterproof flexible membrane switches are in a league of their own. These are not just water-resistant—they’re engineered to withstand moisture, spills, splashes, and even full submersion, depending on the sealing technique used.

One standout feature is the sealed overlay and perimeter. Silicone gaskets, UV-cured adhesives, and heat-sealed edges keep water from entering the inner layers. In some cases, designers use venting systems that allow air to escape while blocking fluids.

Another highlight is chemical resistance. In environments where the switch faces exposure to cleaning agents, disinfectants, or industrial solvents, waterproof flexible membrane switches hold up exceptionally well.

LED backlighting, tactile metal domes, and embossed buttons can all be integrated without compromising waterproof performance.

How do waterproof flexible membrane switches protect your devices?

The biggest risk to most electronic devices? A single drop of water can cause short circuits, corrosion, or complete failure. Waterproof flexible membrane switches create a vital line of defense against this threat.

Because they’re sealed, there are no openings or exposed parts. Water can’t find a way in. Whether it’s rain, humidity, or accidental spillage, these switches block it all.

In medical devices, for example, the stakes are high. A malfunctioning switch could compromise patient safety. That’s why membrane flexible switches with waterproof capabilities are used in diagnostic tools, infusion pumps, and operating room equipment.

Why are waterproof features crucial for certain applications?

In many industries, water and electronics simply don’t mix. Think of marine systems, outdoor equipment, medical gear, or industrial controls. These environments are often harsh—filled with moisture, dirt, or aggressive chemicals.

Without waterproof protection, switches would fail quickly. Repairs are costly. Downtime is disruptive. And in some cases, failures can be dangerous. That’s why waterproof flexible membrane switches are more than a convenience—they’re a necessity.

Additionally, their durability leads to fewer replacements and service calls. This extends product life and boosts user satisfaction. For product designers and engineers, this level of dependability is priceless.

Where are waterproof flexible membrane switches most commonly used?

You’ll find waterproof flexible membrane switches everywhere once you know what to look for. Their versatility makes them ideal across a range of sectors.

In healthcare, they’re used in hospital beds, imaging machines, and portable monitors. Sterility and cleanability are crucial in these environments, and waterproof switches make that possible.

In consumer electronics, think of microwaves, exercise machines, or remote controls. Spills happen. These switches handle them effortlessly.

Outdoor equipment is another major area. Weather-resistant panels for agriculture, marine devices, and industrial machinery all rely on membrane switches that can battle the elements without blinking.

They’re also a staple in defense and aerospace, where mission-critical reliability under extreme conditions is mandatory. Temperature swings, moisture, and vibration are no match for well-built, customized flexible membrane switches.

Conclusion:

Whether you’re looking for customized flexible membrane switches or need reliable waterproof flexible membrane switches for harsh environments, there’s a solution built just for your application.

Need help finding the right switch for your product? Reach out to us today at sales@best-membraneswitch.com—we’re here to guide you every step of the way.

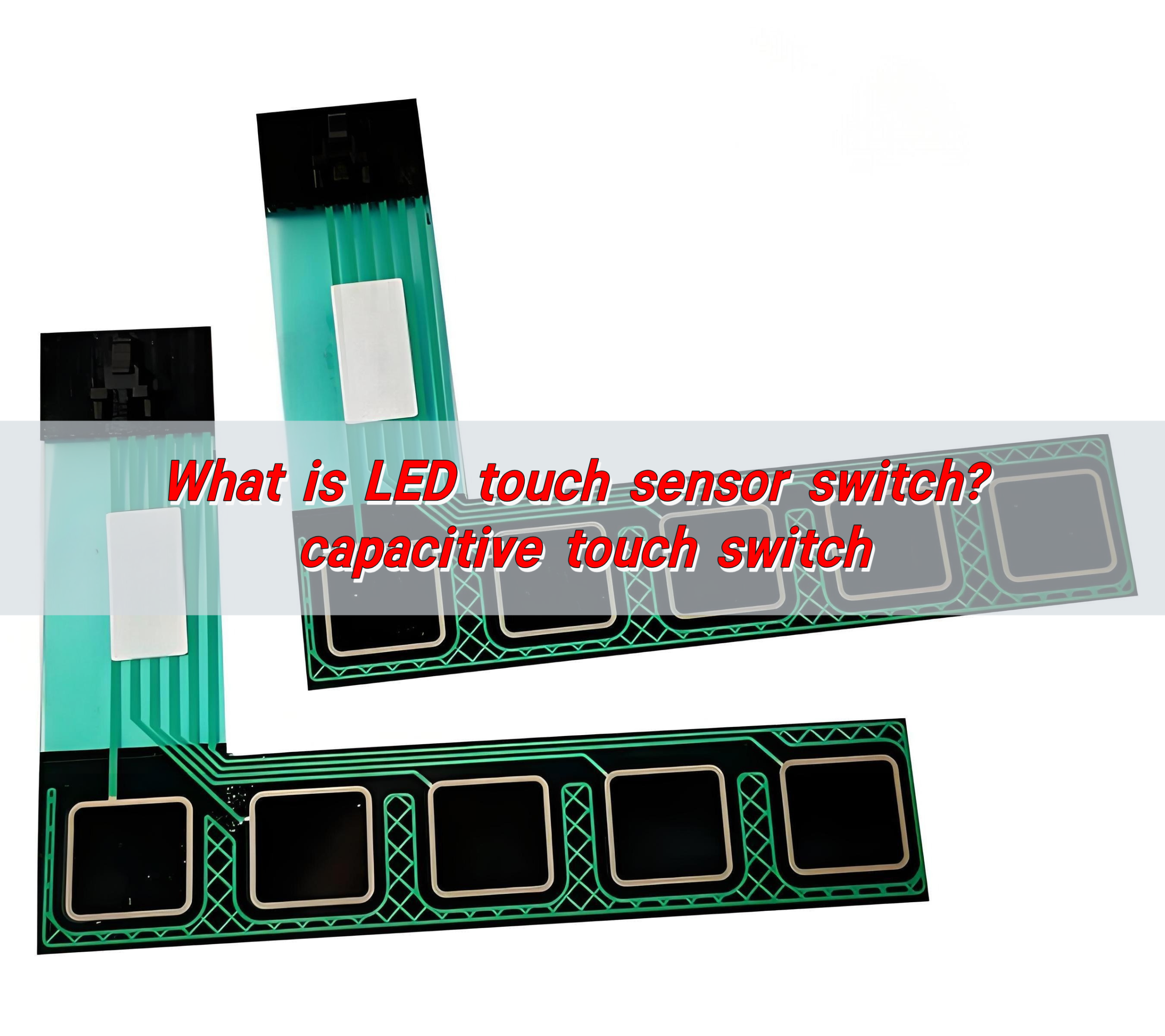

What is LED touch sensor switch? capacitive touch switch

The LED touch sensor switch is an electronic component that combines an LED light and a touch sensor. It controls the on and off of the LED light by touching it, achieving energy-saving and convenient lighting control. It uses capacitive sensing technology to detect human proximity or touch, thereby controlling the on and off of ...

What is IP66 Waterproof? Waterproof Rating of Membrane Switches

The IP66 waterproof rating means that the device is completely protected from dust ingress and can withstand strong water jets. The waterproof rating of membrane switches can usually reach IP67, which is achieved through special processes and materials to ensure its reliability in humid or rainy environments. This performance makes membrane switches suitable for scenes ...

What is click touch membrane switch? custom membrane keypad

Click touch membrane switches are membrane switches that conduct circuits by pressing, have tactile feedback and stable operation, and are widely used in electronic communications, industrial control, medical equipment and other fields. Customized membrane keypad are based on this technology and can choose different materials and layouts according to customer needs. They are both functional ...

Contact us online