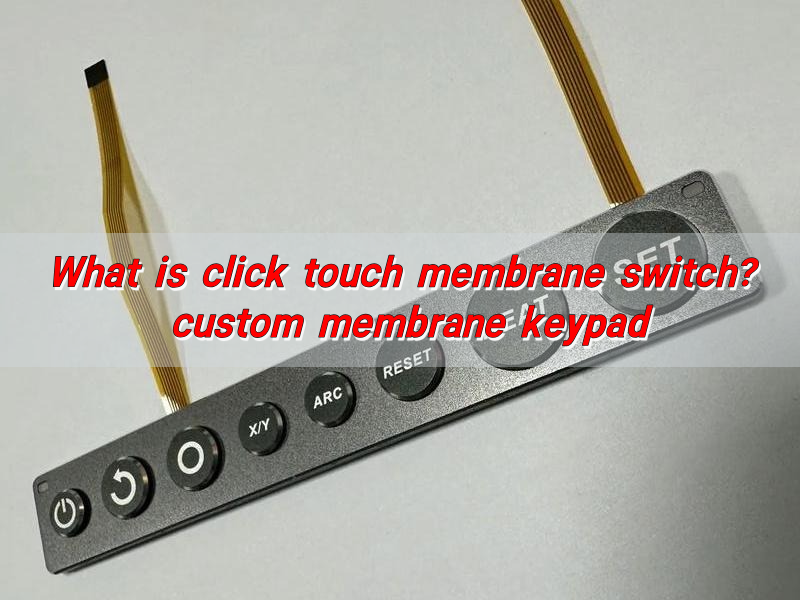

What is click touch membrane switch? custom membrane keypad

What is click touch membrane switch? custom membrane keypad

Click touch membrane switches are membrane switches that conduct circuits by pressing, have tactile feedback and stable operation, and are widely used in electronic communications, industrial control, medical equipment and other fields. Customized membrane keypad are based on this technology and can choose different materials and layouts according to customer needs. They are both functional and decorative, meeting diverse application needs.

What are click touch membrane switches?

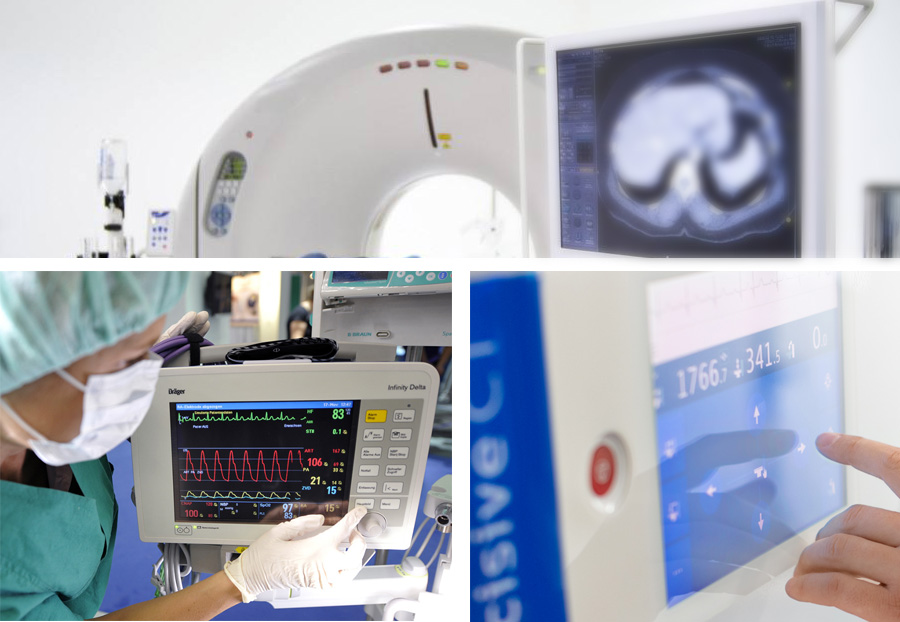

Click touch membrane switches are a type of electronic switch that provides tactile feedback when pressed. Unlike regular membrane switches, which offer no physical feedback, click touch switches are designed to produce a subtle but noticeable “click” or tactile response. This feature makes them an ideal choice for applications where users need to feel or hear that their input has been registered, such as in medical devices, point-of-sale systems, or even household electronics.

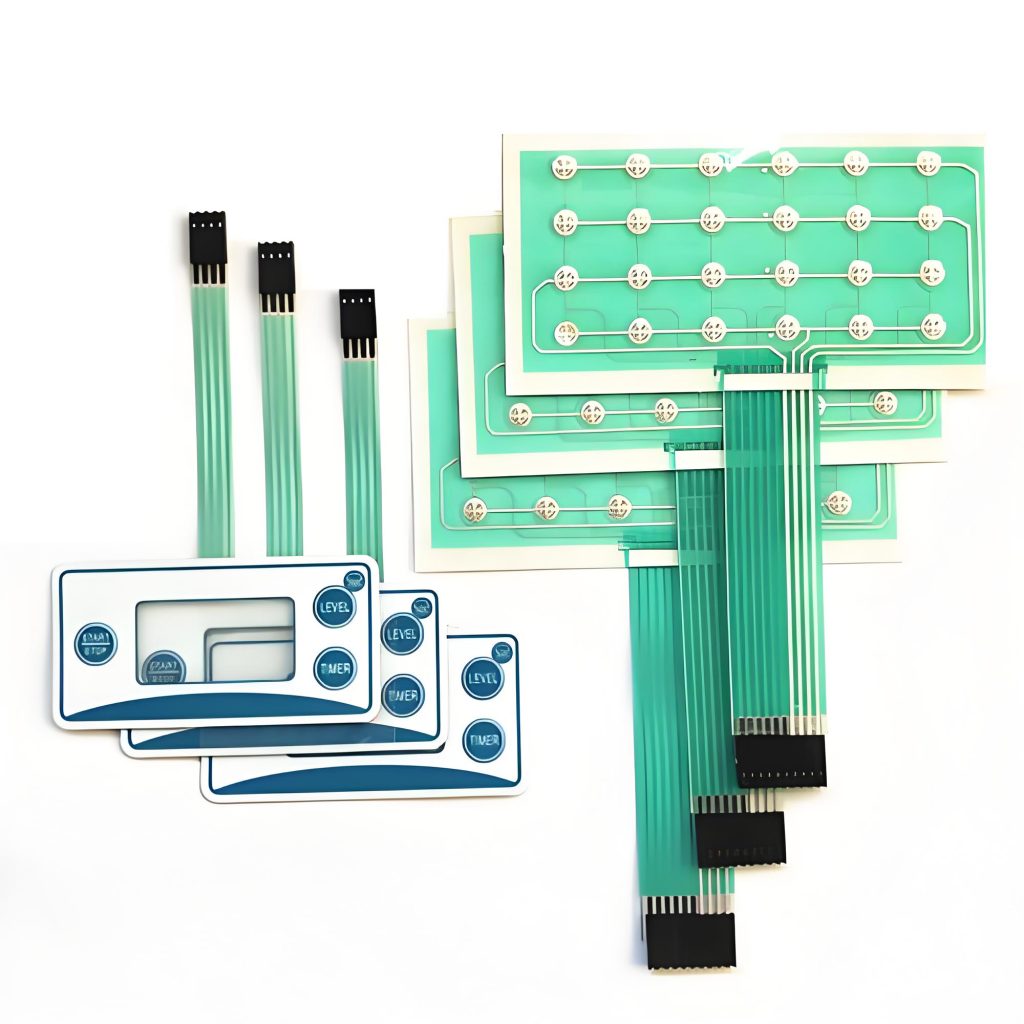

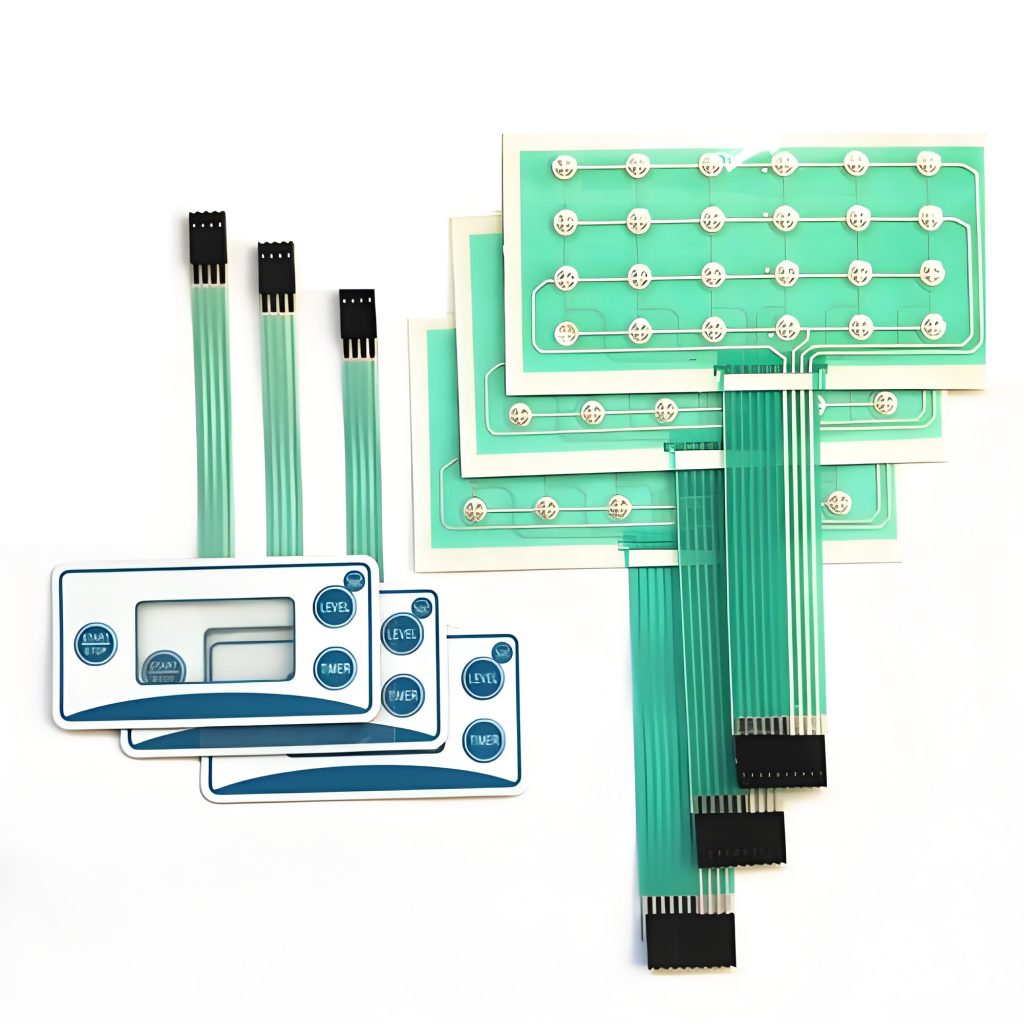

The design of a click touch membrane switch typically consists of a flexible, multi-layered membrane structure. The upper layer features conductive traces that connect to the underlying layers, creating a switch when the button is pressed. The distinctive “click” sensation is often due to a mechanical component integrated into the membrane that snaps back into place after being compressed.

What are the different types of click touch membrane switches?

Click touch membrane switches come in various types, each suited for specific applications. Understanding the different kinds can help you choose the right one for your needs.

- 1、Standard Click Touch Membrane Switches

These are the most common type and are used in a wide range of devices. They provide a crisp, clear click when pressed and are often used in consumer electronics and medical devices where user feedback is crucial.

- 2、Lighted Click Touch Membrane Switches

These switches incorporate backlighting, which can enhance visibility in low-light environments. They are often used in control panels or devices that need to be operated in dark conditions, such as medical equipment or industrial machinery.

- 3、Capacitive Click Touch Membrane Switches

Capacitive switches use the electrical properties of the human body to detect a touch. They don’t require physical pressure to activate and are highly durable. Capacitive touch switches are often used in high-end devices where durability and sleek design are key.

This type uses silicone rubber for the tactile feedback mechanism. They are known for their soft, flexible feel and are often used in environments where comfort and reliability are essential, such as in handheld medical devices.

How are click touch membrane switches manufactured?

The manufacturing process of click touch membrane switches involves several precise steps to ensure the switches provide reliable and consistent performance.

- 1、Design and Prototyping

The first step in manufacturing click touch membrane switches is the design phase. This involves creating prototypes and finalizing the switch’s dimensions, tactile response, and other design elements.

- 2、Layer Construction

The next step is to create the individual layers of the switch. These layers are usually made from flexible materials such as polyester or polycarbonate. The conductive traces are printed onto these layers, which will eventually form the electrical connections when the switch is pressed.

- 3、Tactile Feedback Integration

A key feature of click touch switches is their tactile feedback. Manufacturers integrate small mechanical elements, such as a metal dome or a snap-acting spring, within the switch.

- 4、Assembly

Once the individual layers and components are prepared, the switch is assembled. The layers are stacked, and the mechanical feedback component is positioned. The final assembly is tested for functionality to ensure the switch operates as intended.

- 5、Quality Control

Before the switches are packaged, they go through rigorous quality control checks. This ensures that the switches meet both the functional and aesthetic standards required for the application.

Why choose click touch membrane switches?

Click touch membrane switches are favored in many industries for several key reasons:

- 1、Reliable Feedback

The tactile feedback that comes with click touch membrane switches is one of their strongest benefits. It assures users that their input has been successfully registered, making them ideal for mission-critical applications where reliability is crucial.

- 2、Durability

Click touch membrane switches are built to last. With no moving parts exposed to external elements, they are resistant to wear and tear, which makes them perfect for harsh environments like industrial plants or medical settings.

- 3、Compact Design

These switches are designed to be slim and lightweight, making them ideal for compact devices. The absence of traditional mechanical switches allows for more streamlined, space-efficient designs in everything from appliances to electronic gadgets.

- 4、Cost-Effective

Compared to traditional mechanical switches, click touch membrane switches are generally more cost-effective. The manufacturing process is straightforward and scalable, making them an affordable option for mass production.

- 5、Customizable

Click touch membrane switches can be easily customized to meet specific design requirements. Whether you need specific colors, graphics, or backlighting, these switches can be tailored to suit your needs

What are common click touch membrane switch problems?

While click touch membrane switches are generally reliable, they can experience problems, especially in harsh conditions.

- 1、Loss of Tactile Feedback

One of the most common issues is the loss of tactile feedback, which can occur over time due to wear or exposure to extreme conditions.

- 2、Failure to Register Input

In some cases, the switch may fail to register input properly. This can happen if the conductive traces become damaged or if the switch is not aligned correctly during manufacturing.

- 3、Environmental Damage

Exposure to moisture, heat, or chemicals can degrade the materials used in click touch membrane switches, leading to malfunction.

- 4、Physical Wear

Over time, physical wear from repeated pressing can cause the switch to lose its “click” sensation, making it less responsive and harder to use.

How to test click touch membrane switches?

Testing click touch membrane switches is important to ensure they are functioning properly. Here are some common methods:

- Visual Inspection: The first step is to visually inspect the switch for any signs of physical damage, such as cracks or wear on the surface.

- Functional Testing: Next, test the switch by pressing it and checking if it provides the expected tactile feedback. If there’s no click or the switch fails to register input, there may be an issue with the tactile mechanism or conductive traces.

- Electrical Testing: Using a multimeter, you can test the electrical connections of the switch to ensure the conductive traces are functioning correctly. If there is a break in the circuit, the switch will not work.

- Environmental Testing: In certain applications, you may also want to test the switch in various environmental conditions, such as humidity or extreme temperatures, to ensure it can withstand the intended use.

How to repair click touch membrane switch panels?

Repairing click touch membrane switch panels can be challenging but is possible with the right tools and knowledge.

- Identify the Problem: Whether it’s a loss of tactile feedback or failure to register input, pinpointing the problem is essential.

- Disassemble the Panel: Carefully disassemble the membrane switch panel, taking care not to damage any components.

- Replace Damaged Components: If a specific component, such as the tactile feedback mechanism or a conductive trace, is damaged, replace it with the appropriate part.

- Reassemble and Test: Once the damaged components have been replaced, carefully reassemble the switch panel and test the switch for functionality.

Why opt for custom membrane keypads?

Custom membrane keypads offer a range of benefits that standard keypads cannot match. Here’s why opting for a custom membrane keypad might be the best choice for your device:

Custom keypads can be designed to meet your specific aesthetic and functional requirements. Whether you need specific shapes, colors, or layouts, a custom keypad ensures your design vision comes to life.

- 2、Improved User Experience

By tailoring the layout and tactile feedback, custom keypads can enhance the user experience, making your devices easier and more intuitive to use.

- 3、Branding Opportunities

Custom membrane keypads also provide a unique opportunity for branding. You can integrate logos, branding colors, and specific labels, making the keypad an integral part of your product identity.

- 4、Enhanced Durability

Custom keypads can be built with higher quality materials and extra layers of protection, making them more durable and resistant to wear and environmental factors.

Conclusion:

Click touch membrane switches are an essential part of modern technology, offering reliable tactile feedback and durability. From consumer electronics to industrial machinery, these switches are designed to provide users with a responsive, consistent experience.

If you’re looking for custom solutions or need help with your click touch membrane switches, reach out to us at sales@best-membraneswitch.com

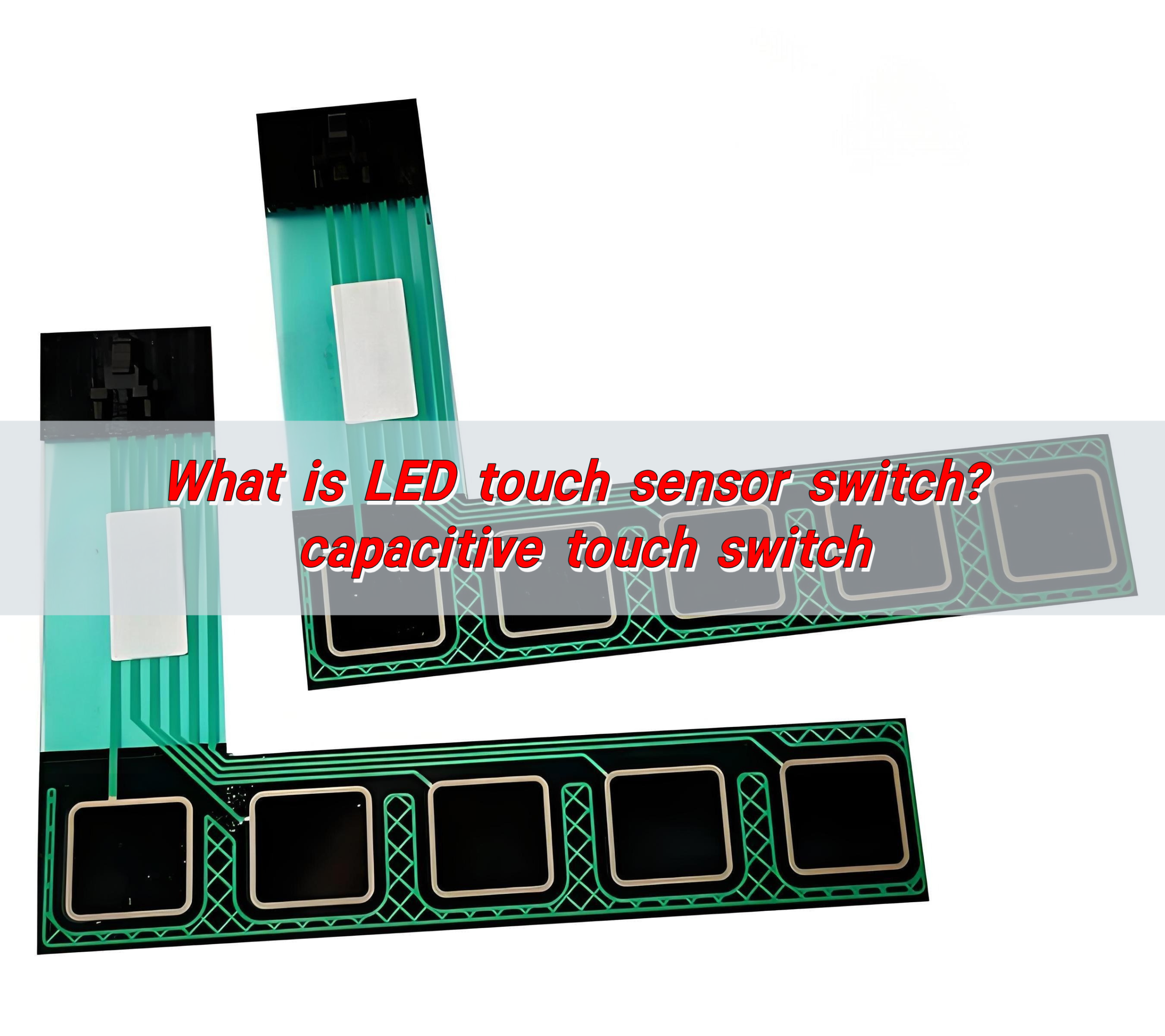

What is LED touch sensor switch? capacitive touch switch

The LED touch sensor switch is an electronic component that combines an LED light and a touch sensor. It controls the on and off of the LED light by touching it, achieving energy-saving and convenient lighting control. It uses capacitive sensing technology to detect human proximity or touch, thereby controlling the on and off of ...

What is IP66 Waterproof? Waterproof Rating of Membrane Switches

The IP66 waterproof rating means that the device is completely protected from dust ingress and can withstand strong water jets. The waterproof rating of membrane switches can usually reach IP67, which is achieved through special processes and materials to ensure its reliability in humid or rainy environments. This performance makes membrane switches suitable for scenes ...

Why are flexible membrane switches a popular choice in modern electronics?

Flexible membrane switches are popular in modern electronic products due to their flexibility, thinness and economy. They not only adapt to complex curved surfaces and achieve flexible design, but also have environmental adaptability such as waterproof and dustproof. In addition, they support multi-function integration, such as LED indicators and sound feedback, to enhance user experience. ...

Contact us online