How do membrane switches work? Understanding membrane switch panel

How do membrane switches work? Understanding membrane switch panel

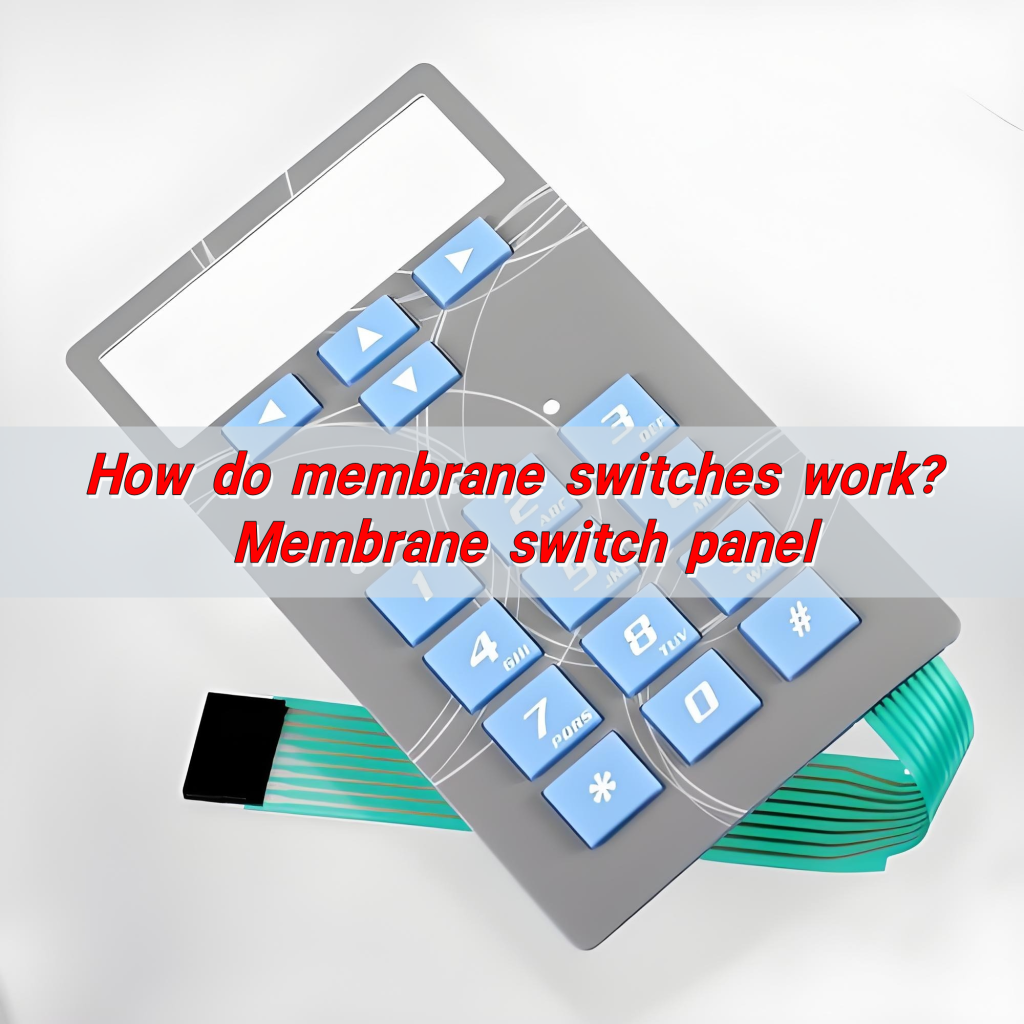

Membrane switch is a new type of electronic component that integrates key functions, indicator elements, and instrument panels. When pressed, the upper circuit contact contacts the lower circuit; when released, the contact rebounds, the circuit is disconnected, and the signal is triggered. Membrane switches have good waterproof and dustproof advantages and are widely used in electronic communications, industrial control, medical equipment and other fields.

The membrane switch panel usually uses a printed circuit board as the base, installs buttons, and is covered with a plastic film panel with a colorful pattern, which has both switch function and decorative properties.

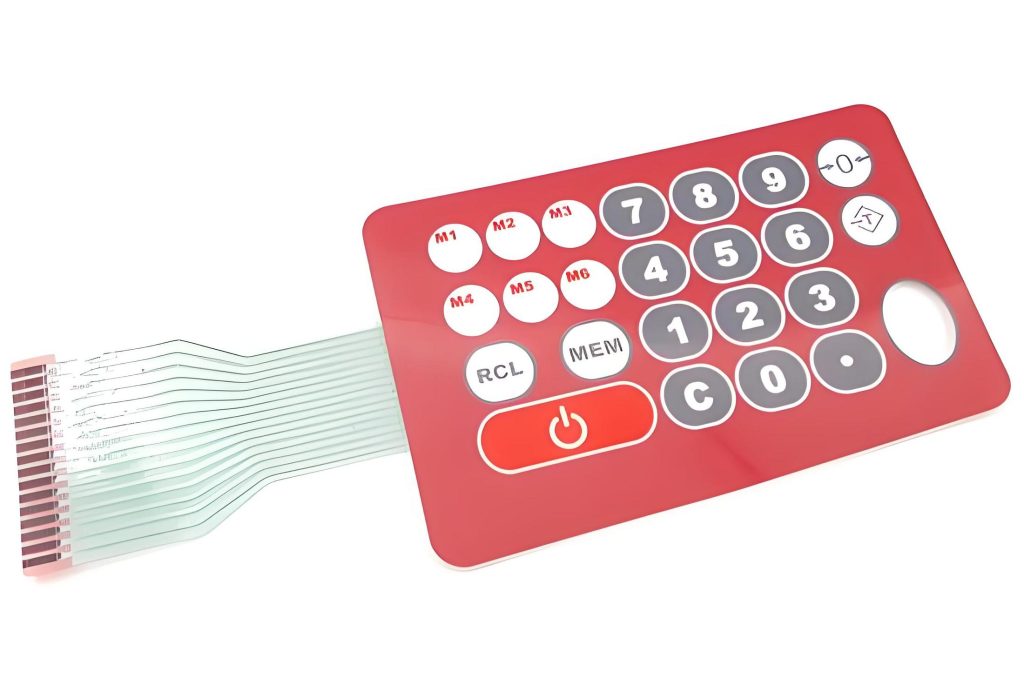

What do membrane switches look like?

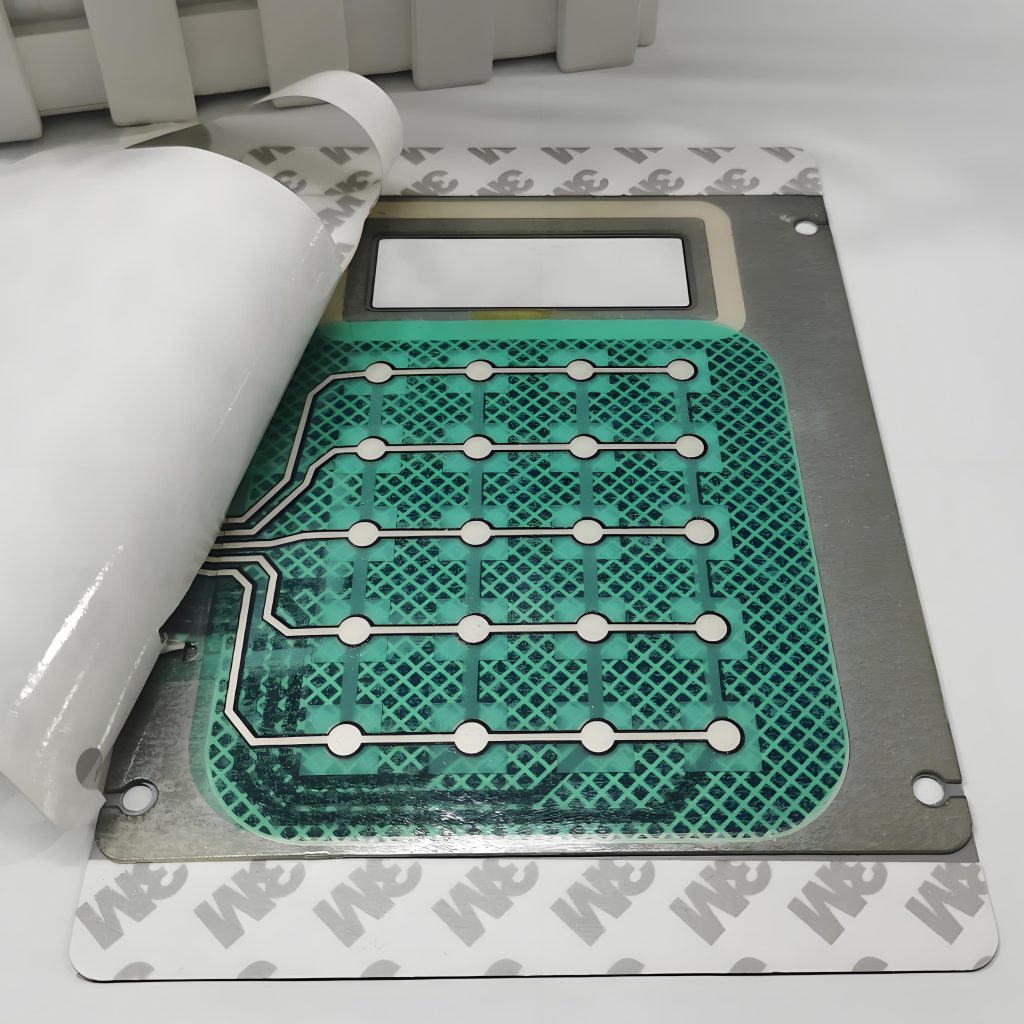

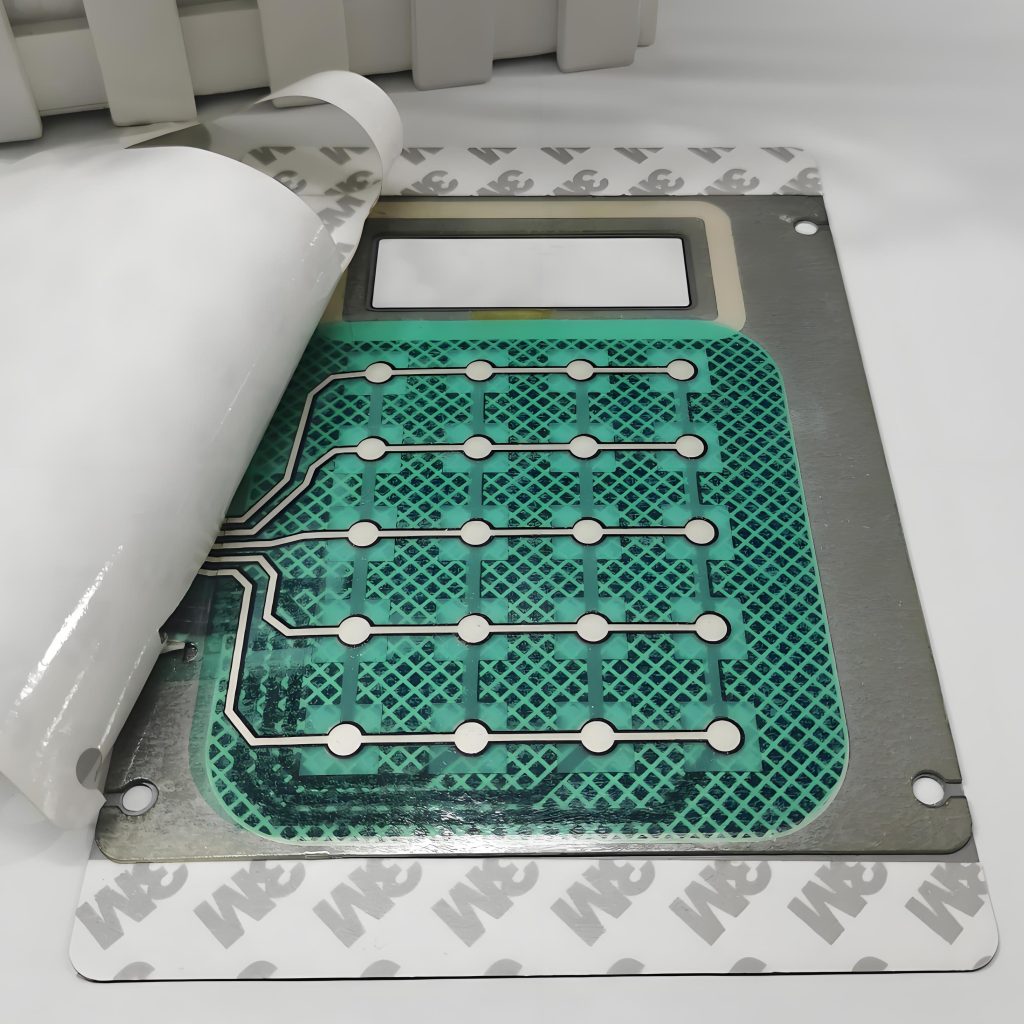

Membrane switches are slim, flexible interfaces made from multiple layers of materials. They usually consist of a graphic overlay, an adhesive layer, a conductive trace, and a spacer layer. The graphic overlay features the printed markings and symbols that users interact with, like buttons or icons. Beneath this layer, a conductive membrane helps complete the circuit when pressed, allowing for electrical signals to pass through and activate a function.

The layers are thin and flexible, so the switch can easily be integrated into different types of devices. Unlike traditional mechanical switches that require a physical moving part, membrane switches operate through pressure, making them more compact and streamlined. The whole design is very lightweight, which helps in reducing the overall weight of electronic devices.

What is the advantage of membrane switch?

There are several key advantages to using membrane switches. The first and foremost is their durability. Membrane switches are built to last, often withstanding millions of keystrokes without significant wear.

Unlike mechanical switches, which rely on moving parts, membrane switches have fewer components that can wear out, making them more reliable in the long run.

Another notable advantage is their resistance to environmental factors. Membrane switches are sealed and can be designed to be waterproof, dustproof, and resistant to chemicals and other harsh conditions. This makes them ideal for applications in industrial environments, medical devices, and consumer electronics, where reliability and resilience are crucial.

Membrane switches also offer significant design flexibility. They can be custom-designed to fit various form factors and integrated into different products. Whether it’s a membrane switch keyboard for a high-tech gadget or a simple membrane switch panel for a household appliance, their adaptability is unmatched.

How long do membrane switches last?

The lifespan of a membrane switch largely depends on its application and the quality of materials used in its construction. On average, a high-quality membrane switch can last between 1 million to 10 million actuations. This means that membrane switches are perfect for long-term use, particularly in products that are expected to endure extensive wear, such as medical equipment, industrial controls, or kitchen appliances.

However, while membrane switches are incredibly durable, their lifespan can be influenced by factors like usage frequency, environmental conditions, and the overall quality of the switch. Properly maintained, membrane switches can remain fully functional for years, ensuring a reliable user experience.

How does membrane switch work?

At its core, a membrane switch is a simple device that operates on the principle of pressure. When a user presses down on a membrane switch, the upper layer (the graphic overlay) makes contact with a conductive trace beneath it. This creates a closed circuit, which sends an electrical signal to the device it is controlling.

The layers of the switch are designed to only make contact at specific points when pressure is applied. This contact triggers the desired function in the device. When the pressure is released, the layers return to their original state, and the circuit is broken, stopping the flow of electricity.

In essence, membrane switches work like a button but without the need for a physical moving part. Instead, pressure activates the circuit, making them much more efficient and durable than traditional mechanical switches.

What is the difference between a membrane switch and a mechanical switch?

While both membrane and mechanical switches serve the same basic function—activating an electrical circuit when pressed—they differ significantly in their design and operation.

- 1. Physical Construction: Mechanical switches typically have moving parts, such as a button or lever that physically moves when pressed. In contrast, membrane switches are flat and rely on pressure-sensitive layers to complete a circuit.

- 2. Durability: Mechanical switches are generally more prone to wear and tear over time due to their moving parts. Membrane switches, on the other hand, have fewer moving components and can last much longer with less maintenance.

- 3. Sensitivity: Membrane switches are often more sensitive to touch, meaning they can be activated with light pressure. Mechanical switches usually require more force, which some users might find less convenient.

- 4. Design Flexibility: Membrane switches offer greater flexibility in design. They can be molded into different shapes and sizes, whereas mechanical switches are more limited in their form factor.

Can you put mechanical switches on a membrane keyboard?

Technically, it is possible to integrate mechanical switches with a membrane keyboard. Typically, membrane keyboards are designed for flexibility and lower cost, while mechanical switches are often chosen for their tactile feedback and durability.

However, in specialized applications, some manufacturers combine the two to achieve the benefits of both. For example, a hybrid membrane-mechanical switch may be used to create a more tactile response while maintaining the flexibility and low profile of a membrane switch.

What is the difference between membrane and dome switch?

Membrane switches and dome switches are both types of non-mechanical switches, but they operate differently.

Membrane switch is based on layers of flexible materials that complete a circuit when pressed. The switch operates by applying pressure to the layers, which activates the circuit.

On the other hand, a dome switch uses a small metal dome that collapses when pressed, causing an electrical contact to form. Dome switches offer tactile feedback, providing a physical “click” that many users find satisfying.

The key difference between the two is in how they feel during use. Membrane switches generally offer a soft, non-tactile feel, while dome switches provide a more pronounced tactile response. Both types are durable, but dome switches tend to be more responsive due to the clicking action.

What are the applications of membrane switches?

Membrane switches are found in a wide range of applications across various industries. Some of the most common include:

- Consumer Electronics: Membrane switches are often used in household appliances like microwaves, washing machines, and air conditioners.

- Medical Devices: In medical equipment, membrane switches are crucial for their durability, ease of cleaning, and resistance to contaminants.

- Industrial Equipment: Membrane switch panels are popular in industrial environments, where their resistance to dust, chemicals, and extreme temperatures is highly valued.

- Automotive: In cars, membrane switches control everything from climate settings to in-dashboard entertainment systems.

- Point of Sale Systems: Retailers and service providers frequently use membrane switches in kiosks and POS systems due to their easy-to-clean surfaces and simple, intuitive interfaces.

Conclusion:

Membrane switches are an essential technology in modern electronics, offering durability, design flexibility, and high reliability. While they differ from mechanical switches in construction and operation, membrane switches can provide many benefits, including longer lifespans and greater environmental resistance.

In summary, if you are looking for a reliable, cost-effective switch for your device, membrane switches are an excellent choice. For more information or inquiries, please reach out to us at sales@best-membraneswitch.com

What is LED touch sensor switch? capacitive touch switch

The LED touch sensor switch is an electronic component that combines an LED light and a touch sensor. It controls the on and off of the LED light by touching it, achieving energy-saving and convenient lighting control. It uses capacitive sensing technology to detect human proximity or touch, thereby controlling the on and off of ...

What is IP66 Waterproof? Waterproof Rating of Membrane Switches

The IP66 waterproof rating means that the device is completely protected from dust ingress and can withstand strong water jets. The waterproof rating of membrane switches can usually reach IP67, which is achieved through special processes and materials to ensure its reliability in humid or rainy environments. This performance makes membrane switches suitable for scenes ...

Why are flexible membrane switches a popular choice in modern electronics?

Flexible membrane switches are popular in modern electronic products due to their flexibility, thinness and economy. They not only adapt to complex curved surfaces and achieve flexible design, but also have environmental adaptability such as waterproof and dustproof. In addition, they support multi-function integration, such as LED indicators and sound feedback, to enhance user experience. ...

Contact us online