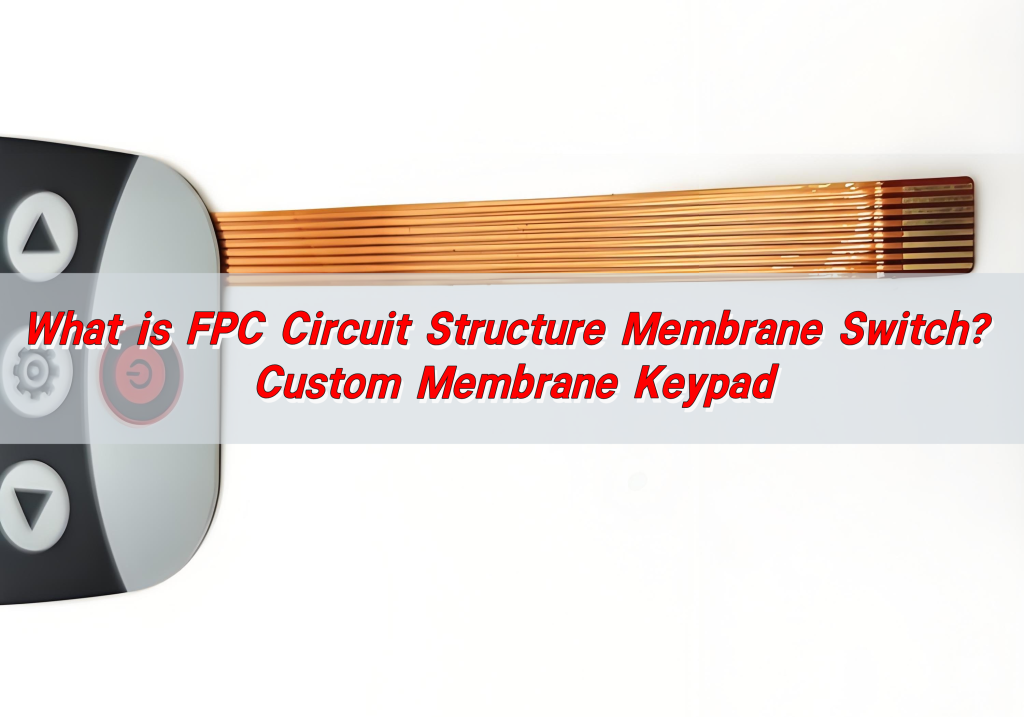

What is FPC Circuit Structure Membrane Switch? Custom Membrane Keypad

What is FPC Circuit Structure Membrane Switch? Custom Membrane Keypad

FPC circuit structure membrane switch is a membrane switch that prints conductive circuits on a flexible substrate. It uses thin, flexible materials, has the advantages of durability and environmental protection, and is widely used in consumer electronics such as mobile phones and tablets, as well as medical devices, automotive electronics and other fields.

FPC membrane switches use advanced printing technology to achieve efficient and flexible circuit connections, and have good insulation and heat resistance. In addition, FPC membrane switches also support customized services, and can design shapes, colors and functions according to customer needs to meet diverse market needs.

What is an FPC membrane switch?

FPC membrane switch is a thin, flexible electronic switch using a Flexible Printed Circuit (FPC) as its core structure. Unlike traditional PET-based membrane switches, which use printed silver conductive ink, FPC switches use copper traces, ensuring better conductivity and longevity. The circuit layers are made from polyimide (PI), making them heat-resistant and mechanically robust.

This type of switch is lightweight, bendable, and ideal for compact and high-end applications. Industries like medical, aerospace, and industrial automation prefer FPC membrane switches for their reliability. These switches work by pressing a button, which closes an electrical circuit, sending signals to the device.

How to design an FPC membrane switch?

Designing an FPC membrane switch requires precision. The process starts with defining the circuit layout. Engineers design the circuit paths using copper traces instead of printed conductive ink. This ensures stronger electrical performance and reduces resistance issues.

Key design factors include:

- Circuit Layer: The FPC layer must have proper copper thickness to handle electrical loads.

- Button Response: The tactile feedback must be responsive yet durable. Metal domes are often used.

- Connector Placement: Common connectors include ZIF (Zero Insertion Force) or FPC connectors.

- Shielding & Insulation: EMI shielding is essential to prevent interference in sensitive electronics.

Engineers also consider tail length, button layout, and LED integration for enhanced usability. Each component must fit seamlessly to maintain the switch’s durability and reliability.

What are the materials of an FPC membrane switch?

High-quality materials define the performance and longevity of an FPC membrane switch. The key materials include:

- Polyimide (PI) Film: This forms the base of the flexible printed circuit. It offers heat resistance, durability, and chemical stability.

- Copper Foil: Unlike traditional printed circuits, FPC switches use etched copper traces for better conductivity.

- Adhesive Layers: Acrylic or pressure-sensitive adhesives bond the layers together. These adhesives ensure strong adhesion and flexibility.

- Top Graphic Layer: Made from polycarbonate or polyester, this layer includes printed symbols and protective coatings.

- Metal Domes (Optional): These provide tactile feedback when pressed, making the switch more responsive.

The use of premium materials ensures better performance and longevity. Cheap materials lead to poor conductivity, peeling, or breakdown over time.

What is the resistance of a FPC membrane switch?

One key advantage of FPC membrane switches is their low electrical resistance. Since they use copper traces instead of silver ink, resistance is significantly lower. This ensures faster signal transmission and better power efficiency.

Typical resistance values for an FPC switch range from 10 to 100 ohms per circuit, depending on the circuit length, copper thickness, and design. Lower resistance means less power loss, improved response time, and longer switch life.

What are the advantages of an FPC membrane switch?

FPC membrane switches stand out due to their superior performance and adaptability. Here’s why they are the preferred choice:

- Highly Durable: Copper traces last longer than printed silver ink. These switches withstand over one million presses.

- Flexible & Lightweight: The bendable structure allows installation in tight spaces. Perfect for compact devices.

- Low Electrical Resistance: Ensures fast signal transmission and low power consumption.

- Better Heat & Chemical Resistance: The polyimide base withstands high temperatures and harsh conditions.

- Customizable: Designs can be fully tailored, including button layout, connectors, and backlighting.

- Reliable Performance: No oxidation issues like silver ink circuits, making them ideal for high-end applications.

These advantages make FPC membrane switches the best choice for demanding environments. They ensure long-term reliability, precision, and user-friendly operation.

What are the disadvantages of an FPC membrane switch?

While FPC membrane switches offer many benefits, a few challenges exist:

- Higher Cost: Compared to PET-based membrane switches, FPC switches cost more due to the etching process and copper materials.

- Complex Manufacturing: Requires precise circuit etching, plating, and shielding, making production more intricate.

- Limited Mass Production Efficiency: Though reliable, the production speed is slower compared to screen-printed circuits.

Despite these drawbacks, the long-term benefits outweigh the initial investment. High-end industries prioritize performance and durability, making FPC switches worth the cost.

Are FPC membrane switches hot swappable?

Hot swapping refers to replacing a component without turning off the system. FPC membrane switches are generally not hot-swappable, as they are integrated into the device. However, if designed with a ZIF or FPC connector, they can be replaced easily without soldering.

For applications needing frequent replacements, a well-designed connector-based system is recommended.

Where are FPC membrane switches used?

FPC membrane switches are used in various high-precision industries due to their reliability and adaptability:

- Medical Equipment: Found in diagnostic devices, handheld medical tools, and monitoring systems.

- Industrial Control Panels: Used in factory automation, robotics, and industrial machinery.

- Aerospace & Defense: Applied in navigation systems, military devices, and avionics panels.

- Consumer Electronics: Keypads in smart home devices, wearables, and remote controls.

- Automotive Controls: Used in touch-sensitive dashboard panels and control systems.

Their flexible design, high reliability, and lightweight nature make them perfect for modern applications.

Conclusion:

FPC circuit structure membrane switches provide exceptional reliability, low resistance, and superior flexibility. Their advanced copper circuit technology, heat resistance, and customization potential make them the perfect choice for high-end applications.

For custom FPC membrane switches or custom membrane keypads, getting expert guidance ensures the best performance and durability. If you need a custom solution, reach out to sales@best-membraneswitch.com for professional support.

Tags:

What is a PCB Membrane Switch? PCB Switch Types

PCB membrane switch is a switch based on rigid circuit board, suitable for application scenarios that require stronger mechanical stability and reliability. It is usually composed of multiple layers of film, including conductive film, circuit breaker film and display film, etc., and the circuit is turned on and off by touch or press operation. The ...

What is LGF Membrane Switch? Backlit Membrane Switch

LGF membrane switch is a membrane switch that uses light guide film technology, which can achieve uniform light emission and good visual effects. LGF membrane switches are usually composed of multiple layers of film, including conductive film, circuit breaker film and display film, etc., and the circuit is turned on and off by touch or ...

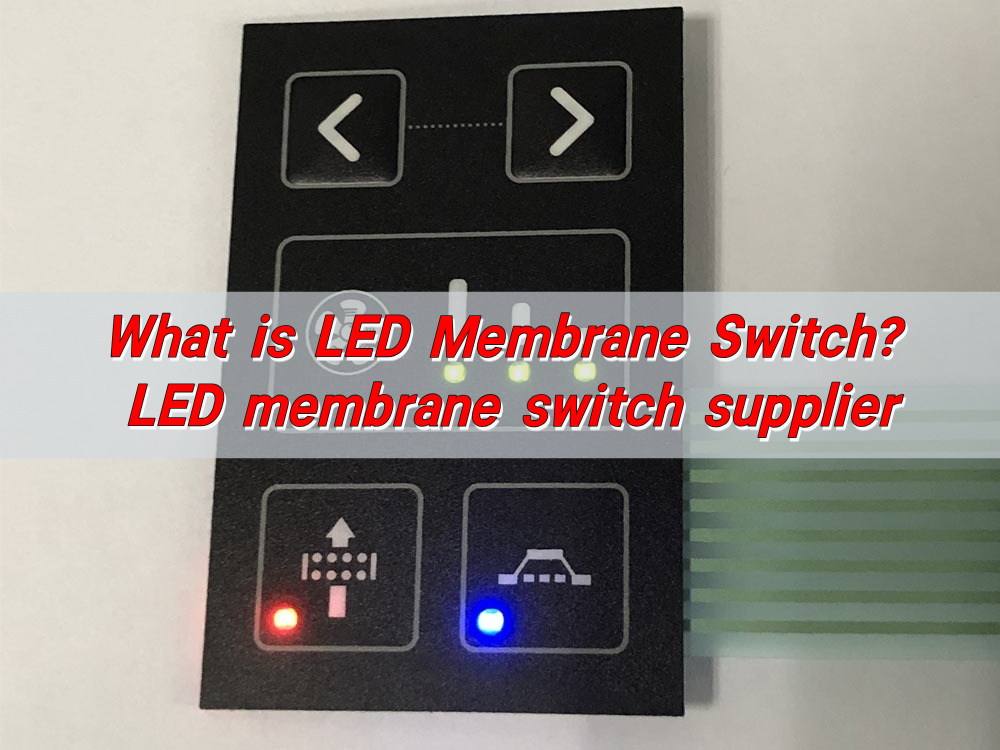

What is LED Membrane Switch? LED membrane switch supplier

LED membrane switch is an electronic component that combines LED light with membrane switch technology. It not only has the functions of traditional membrane switch, but also provides intuitive visual feedback and decorative effects through LED light. This kind of switch is usually composed of multiple layers of film, including conductive film, circuit breaker film ...

Contact us online