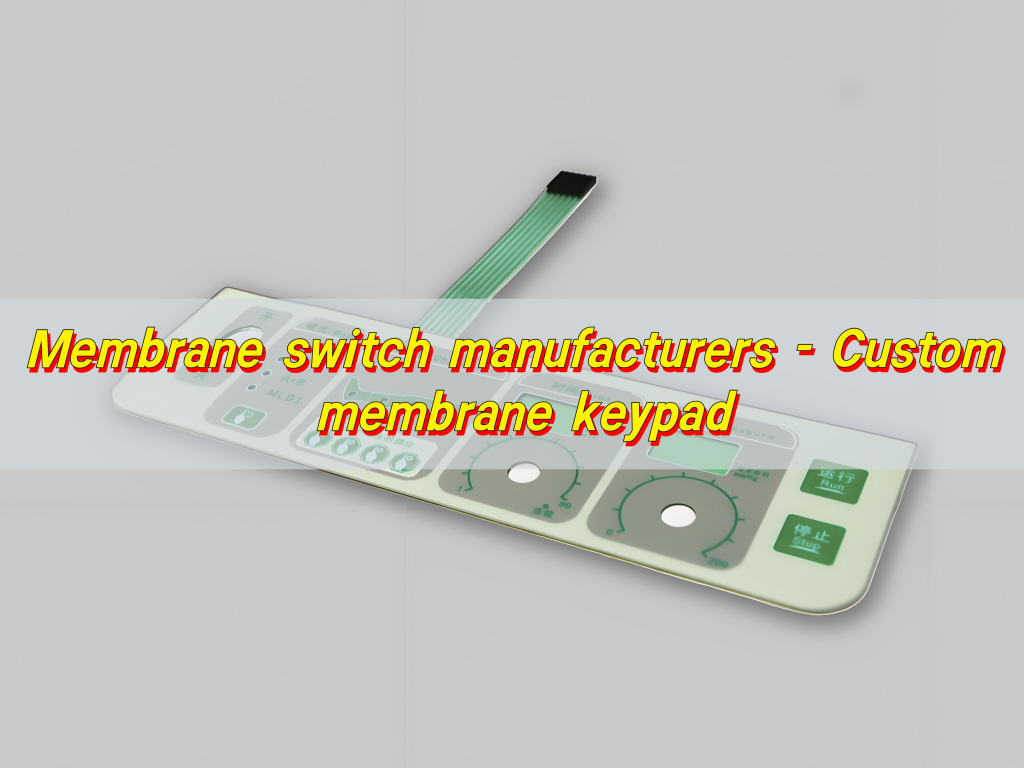

Membrane Switch Manufacturers – Custom Membrane Keypad

Membrane Switch Manufacturers – Custom Membrane Keypad

Membrane switch is an electronic switch composed of multiple layers of film. It activates the circuit by touching or pressing, thereby controlling the electronic device. As an important component in modern electronic devices, membrane switches are widely used in various products.

Yuan Electronics is a professional membrane switch manufacturer. We provide a variety of membrane switches, including resistive, capacitive touch, etc., and support customized services. They are widely used in medical, industrial control, consumer electronics and other fields.

What are membrane switches?

Membrane switch is a low-profile, pressure-sensitive keypad that allows users to control electronic devices. Unlike mechanical switches, these have a flat surface with no moving parts. Instead of physical buttons, they use pressure to trigger circuits beneath a flexible top layer.

Membrane switches are used in everything from medical equipment to industrial machinery. Their durability, ease of cleaning, and compact design make them ideal for environments requiring precision and hygiene.

How is a membrane switch composed?

Membrane switches may look simple, but their design is sophisticated. They typically consist of multiple layers:

- Graphic Overlay: The topmost layer, printed with symbols or instructions. This is the user interface.

- Adhesive Spacer: Keeps the layers separated and allows for movement when pressed.

- Circuit Layer: Conductive traces form the electrical circuit, usually made of silver or copper.

- Rear Adhesive: Secures the switch to its mounting surface.

Each layer plays a vital role in ensuring responsiveness, durability, and functionality.

What are the materials of membrane switches?

1. Polyvinyl chloride PVC

Polyvinyl chloride (PVC) is stable to acids, alkalis and salts at room temperature. It has good wear resistance, self-extinguishing flame resistance, sound and vibration reduction, good electrical insulation, and poor thermal stability. It is suitable for low-priced ordinary signs and panels.

2. Polycarbonate

Polycarbonate has high light transmittance, low water absorption, good dimensional stability, excellent bending, tensile and compressive strength, excellent heat resistance, cold resistance, electrical insulation and atmospheric aging resistance. However, it has poor chemical resistance, poor fatigue resistance, and is prone to stress cracking.

Generally, it has the widest range of applications. In addition to meeting the requirements of most membrane switch panels, the high light transmittance of glossy PC can meet the requirements of LCD display windows.

3. Sanded polyester (PET)

Sanded polyester (PET) has good chemical resistance, is insoluble in general organic solvents, and is not alkali-resistant. It has excellent mechanical properties, electrical properties, rigidity, hardness and the highest toughness among thermoplastics, low water absorption, excellent wear resistance and friction resistance, and high dimensional stability. The tensile strength is comparable to that of aluminum film and much higher than that of PC and PVC.

Low price Because the surface is difficult to process into a matte type, textured PET is more expensive. It is the most ideal substrate for making membrane switch circuits. Among them, textured PET is suitable for products with high surface requirements or with LCD display windows.

How do membrane switches work?

When a user presses a button, the top layer flexes downward. This movement causes the conductive traces on the circuit layer to connect, completing the circuit. Once pressure is released, the layers return to their original position, breaking the connection.

This contact mechanism enables smooth and reliable operation without mechanical wear. The sealed design keeps dust, moisture, and contaminants away from internal components, extending the switch’s lifespan.

What are the types of membrane switches?

Membrane switches come in various designs, each suited for specific applications:

Epoxy technology is a friendly and easy to operate technology that combines the durability of epoxy with the convenience of a pushbutton switch. It is essentially a membrane switch that uses a special epoxy material for its operation.

Unlike traditional switches, which can be prone to wear and tear, Epoxy Membrane Switch is robust and long-lasting, ensuring that your devices remain in top working condition.

Epoxy Membrane Switch operates by pressing on a special membrane, which causes a change in the switch’s state. This unique mechanism makes it not only durable but also highly reliable. Its reliability is further enhanced by its ability to handle high-pressure applications.

A Flexible Printed Circuit (FPC) membrane switch is a type of user interface that utilizes flexible printed circuits as the key component. Compared with traditional membrane switches by using the silver paste printed flex as the circuit layer, the FPC membrane switch is made from Polyimide copper etched FPC circuits.

Copper Flex Membrane Keypads, also known as Copper Flex Printed Circuit Membrane Switches, are essential input devices in the electronics industry. They are designed to offer a user-friendly interface for a wide range of applications, from consumer electronics to industrial machinery.

Because FPC circuit structure membrane switch is made by flex circuit board, it has high precision, low resistance value and more stable circuit function.

PCB always refers to FR4 PCB. FR-4, is a widely acceptable international grade destination for fiberglass reinforced epoxy laminated that are flame retardant (self-extinguishing). After add copper layer on one or each side FR4, it become to Copper Clad Laminate (CCL), and this is the non-conductive core material for normal printed circuit board (PCB). Printed circuit board using FR4 as core material will be named as “FR4 PCB”.

The PCB membrane switch utilizes a PCB as the main structure and support substrate, with the membrane switch on the front of the PCB, and some other components such as connectors on the backside of the PCB.

A PET membrane switch, also known as a Polyester membrane switch, is a type of user interface or control panel commonly used in various electronic devices and equipment. It consists of several layers of materials, with a polyester film forming the base layer. This film is typically coated with conductive materials and insulating inks to create a functional interface. Polyester material is ideal for tactile membrane switch because of its lower cost, thin thickness, bendable features, and high tensile strength.

Silicone Rubber Membrane Switch

A silicone rubber membrane switch, also known as a rubber keypad or rubber dome switch, is a type of user interface device used in electronic devices and control panels. It typically consists of a flexible rubber or silicone membrane with embedded conductive carbon pills or metal domes.

When pressure is applied to specific areas on the membrane, these elements make contact with the circuit, completing an electrical connection. Membrane switches are known for their durability, tactile feedback, and customization options, making them widely used in various electronic devices and control panels for their reliable and cost-effective user interface solutions.

Membrane vs. Mechanical Switch

Membrane and mechanical switches serve the same function but operate differently. Mechanical switches use physical components to activate circuits, while membrane switches rely on pressure-sensitive layers.

Key Differences:

- Durability: Membrane switches last longer due to fewer moving parts. Mechanical switches wear out faster due to physical stress.

- Maintenance: Membrane switches are sealed, making them resistant to dust and moisture. Mechanical switches require regular cleaning.

- Cost: Membrane switches are more affordable to manufacture, reducing overall product costs.

- Customization: Membrane technology allows for unique designs, including backlighting, flexible layouts, and integrated displays.

For most applications, membrane switches provide a superior balance of durability, functionality, and cost-effectiveness.

What are the advantages and disadvantages of the membrane switch?

Advantages:

- Compact Design: Thin and lightweight, saving space in devices.

- Water & Dust Resistant: Sealed surface prevents damage from contaminants.

- Customizable: Various designs, colors, and lighting options available.

- Easy to Clean: No gaps for dirt buildup, ensuring hygiene.

- Reliable Performance: Long lifespan with consistent responsiveness.

- Cost-Effective: Lower production costs than mechanical alternatives.

Disadvantages:

- Less Tactile Feedback: Some designs lack the satisfying click of mechanical buttons.

- Limited Key Travel: Press depth is shallow, which may feel unfamiliar to some users.

Despite these minor drawbacks, membrane switches remain a top choice in industries requiring high reliability and easy maintenance.

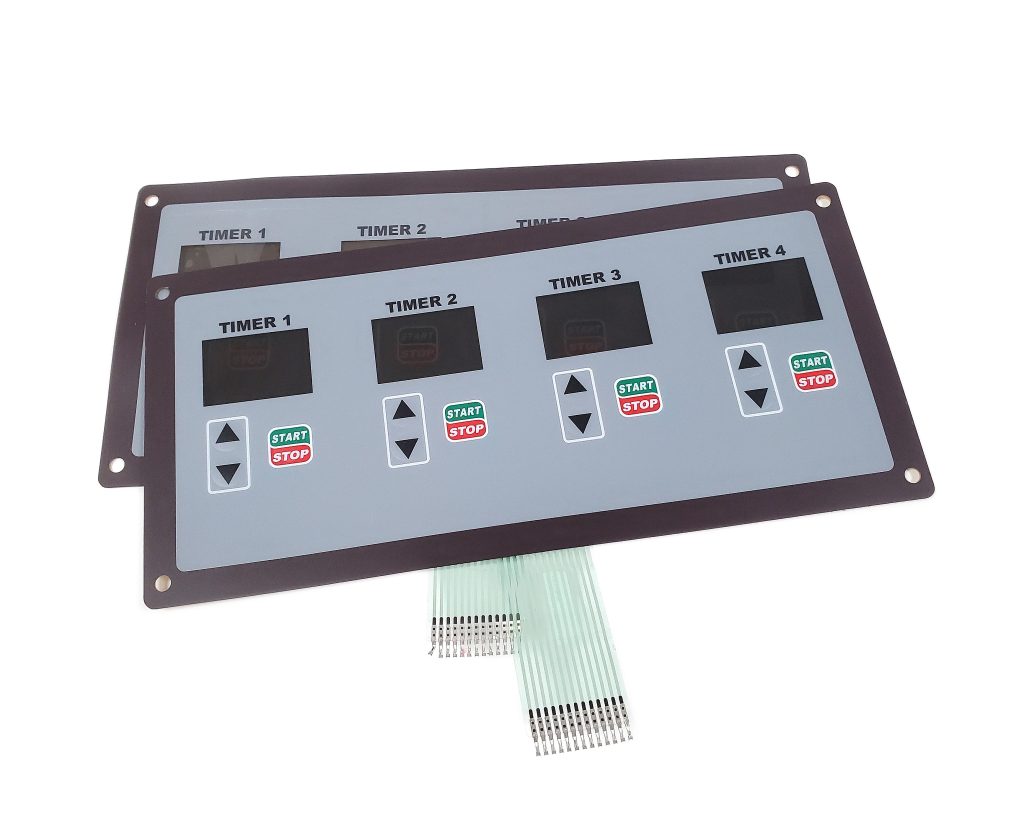

What are the applications of membrane switches?

Membrane switches are widely used in various industries. Their versatility makes them ideal for:

- Medical Equipment: Used in hospital devices due to their sealed, easy-to-clean design.

- Industrial Controls: Found in machinery where durability and resistance to harsh conditions are essential.

- Consumer Electronics: Used in household appliances, remote controls, and fitness equipment.

- Automotive Controls: Integrated into dashboards and vehicle control systems for efficient operation.

- Military & Aerospace: Designed for extreme conditions, ensuring reliability in mission-critical applications.

- Telecommunications: Applied in communication devices where quick, accurate input is necessary.

From life-saving medical devices to everyday household gadgets, membrane switches enhance usability, durability, and performance across industries.

Membrane switch supplier & Membrane switch manufacturers

As a trusted membrane switch manufacturer, we specialize in providing high-quality custom membrane switches for a wide range of industries. With years of expertise in membrane switch manufacturing, we provide customized solutions that meet precise performance and durability standards.

Our Advantages:

- Custom Engineering and Design: Our team works closely with customers to develop custom membrane keypads and switch panels that meet exact requirements, from layout and materials to tactile feedback and backlighting.

- Advanced Manufacturing: Using state-of-the-art production technology to ensure precise circuit printing, seamless lamination, and consistent quality.

- High-Quality Materials: Using durable films, conductive inks, and adhesives to create long-lasting membrane switches that resist wear, moisture, and stains.

- Strict Quality Control: Each product is rigorously tested before shipment. From electrical performance checks to environmental resistance testing, we ensure that each switch will perform perfectly.

- Flexible Production and Fast Turnaround: Whether you need a small batch prototype or large-scale production, we can deliver efficiently.

- Committed to Innovation: We continue to improve technology to provide more responsive, durable, and user-friendly membrane switches.

With a reputation built on precision, reliability and customer-centric solutions, YuAn Electronics are a leading membrane switch supplier.

Conclusion:

Membrane switches provide a versatile, durable, and cost-effective solution for various industries. Their customization options, sealed design, and long lifespan make them superior to mechanical alternatives in many applications.

When selecting a membrane switch manufacturer, look for quality, customization, and reliability. The right partner ensures you get precise, high-performance membrane switch panels tailored to your needs. For high-quality custom membrane keypads and switch solutions, contact sales@best-membraneswitch.com today.

Tags:

What is a PCB Membrane Switch? PCB Switch Types

PCB membrane switch is a switch based on rigid circuit board, suitable for application scenarios that require stronger mechanical stability and reliability. It is usually composed of multiple layers of film, including conductive film, circuit breaker film and display film, etc., and the circuit is turned on and off by touch or press operation. The ...

What is LGF Membrane Switch? Backlit Membrane Switch

LGF membrane switch is a membrane switch that uses light guide film technology, which can achieve uniform light emission and good visual effects. LGF membrane switches are usually composed of multiple layers of film, including conductive film, circuit breaker film and display film, etc., and the circuit is turned on and off by touch or ...

What is LED Membrane Switch? LED membrane switch supplier

LED membrane switch is an electronic component that combines LED light with membrane switch technology. It not only has the functions of traditional membrane switch, but also provides intuitive visual feedback and decorative effects through LED light. This kind of switch is usually composed of multiple layers of film, including conductive film, circuit breaker film ...

Contact us online