What is Emergency Stop Button? Emergency Stop Button Symbol

What is Emergency Stop Button? Emergency Stop Button Symbol

Emergency stop buttons, commonly known as e-stops, are safety devices integral to industrial and commercial setups. These buttons are designed to halt machinery and equipment during emergencies, preventing accidents, injuries, and damage. Today, let’s introduce what is an emergency stop button and how to stick the membrane switches on it.

What is an Emergency Stop Button?

An emergency stop button is a manually operated control designed to bring machinery and equipment to an immediate halt in hazardous situations. Unlike standard stop controls, e-stops are an override mechanism that ensures safety even if other controls fail. Typically, these buttons are red with a yellow background to stand out. They are strategically placed within easy reach of operators, enabling quick action during emergencies.

Emergency stop buttons are used across industries, including manufacturing, construction, and medical equipment. Their simple design belies their critical importance, acting as a safeguard against unexpected risks. By instantly disconnecting power or activating braking systems, they protect both personnel and equipment.

Emergency Stop Button Symbol

The symbol for an emergency stop button is universally recognized, ensuring clarity across various industries and regions. It generally features a red circle or button on a yellow background. In some designs, the symbol includes arrows pointing inward to indicate the button’s functionality of stopping operations.

What Does an Emergency Stop Button Do?

The emergency stop button serves a straightforward yet essential purpose: to halt machinery or equipment instantly. When activated, it interrupts the power supply or engages mechanical brakes, stopping all operations. This immediate action prevents accidents, minimizes damage, and ensures safety.

For example, in a manufacturing plant, pressing the e-stop can prevent machinery from continuing its motion if a worker’s hand is at risk of getting caught. Similarly, in conveyor systems, the e-stop button can stop materials from piling up and causing blockages or damage.

What Are the Regulations for Emergency Stop Buttons?

Emergency stop buttons are governed by international standards, prominent regulations include:

- ISO 13850: This standard specifies the design, location, and operation of emergency stop devices. It ensures they are accessible, visible, and capable of halting equipment safely.

- IEC 60204-1: This electrical standard covers the safety of machinery, including the installation and functionality of e-stops. It requires regular testing and maintenance to confirm operational readiness.

Compliance with these standards is non-negotiable for manufacturers and operators. Regular inspections and adherence to guidelines ensure the buttons function correctly when needed most. Failing to meet these regulations can result in fines, equipment failure, or worse, workplace accidents.

Are Emergency Stop Buttons Normally Open or Closed?

Emergency stop buttons are typically designed as normally closed circuits. In a normally closed configuration, the circuit is complete during regular operation, allowing power to flow. When the button is pressed, the circuit is interrupted, cutting off power and stopping the machine.

This fail-safe design is critical in ensuring reliability. If the circuit becomes disconnected due to damage or wear, the system will automatically stop, preventing unintentional operation of the machinery.

What Happens When You Press the Emergency Button?

When you press an emergency stop button, several actions occur simultaneously to halt operations:

- Power Disruption: The button interrupts the electrical supply to the equipment, stopping its operation immediately.

- Braking Mechanism Activation: In systems with mechanical components, brakes may engage to stop moving parts.

- System Lockdown: Most emergency stop systems lock the equipment in a stopped state until the button is manually reset. This ensures the issue is resolved before operations resume.

The impact of pressing an e-stop extends beyond machinery. It creates a moment of pause, allowing operators to assess the situation and address the underlying issue.

When to Use an E-Stop?

Emergency stop buttons should only be used in situations where safety is at risk or when immediate action is required to prevent harm. Common scenarios include:

- Equipment Malfunctions: When machinery behaves unpredictably, posing a threat to operators or surrounding equipment.

- Unexpected Hazards: If debris or objects fall into operating machinery, pressing the e-stop can prevent damage or injury.

- Personnel Safety Risks: When someone is in close proximity to dangerous moving parts, activating the e-stop can avert accidents.

It is essential to train employees on when and how to use emergency stop buttons. Misuse or overuse can lead to unnecessary downtime and wear on the system, reducing its reliability in actual emergencies.

Why Are Emergency Stop Buttons Critical for Workplace Safety?

Emergency stop buttons play a vital role in maintaining a safe and secure workplace. Their ability to halt operations instantly can save lives, protect equipment, and prevent costly downtime. By acting as a fail-safe mechanism, they add an extra layer of protection that goes beyond regular controls.

In addition to their practical benefits, e-stops demonstrate a company’s commitment to safety. Employees feel more confident working in environments equipped with effective safety measures, leading to better morale and productivity.

How to Stick a Membrane Switch on Emergency Stop Buttons?

Adding a membrane switch to an emergency stop button enhances its functionality and protection. Here’s how to do it effectively:

- Prepare the Surface: Clean the emergency stop button thoroughly to remove any dirt, oil, or residue. Use a lint-free cloth and an industrial cleaner for the best results.

- Select the Right Adhesive: Choose a high-quality adhesive or double-sided industrial tape designed to withstand mechanical stress and environmental factors like heat and moisture.

- Align the Membrane Switch: Carefully position the membrane switch over the emergency stop button. Ensure the graphics, tactile feedback, and button placement align perfectly.

- Apply Pressure: Press the membrane switch firmly onto the button to ensure a secure bond. Avoid applying uneven pressure, as this could lead to air bubbles or poor adhesion.

- Test the Functionality: After attaching the membrane switch, test the emergency stop button to confirm it operates smoothly. The switch should not interfere with the button’s movement or responsiveness.

Proper installation ensures the durability and reliability of the membrane switch, even in demanding industrial environments. Regular checks and maintenance can further enhance its lifespan and performance.

By attaching membrane switches and exploring advanced features, you can further enhance the functionality of these vital devices. For reliable membrane switch solutions for e-stops, turn to Danyu electronics, a leader in safety equipment. Contact us at sales@best-membraneswitch.com to explore how our products can meet your needs.

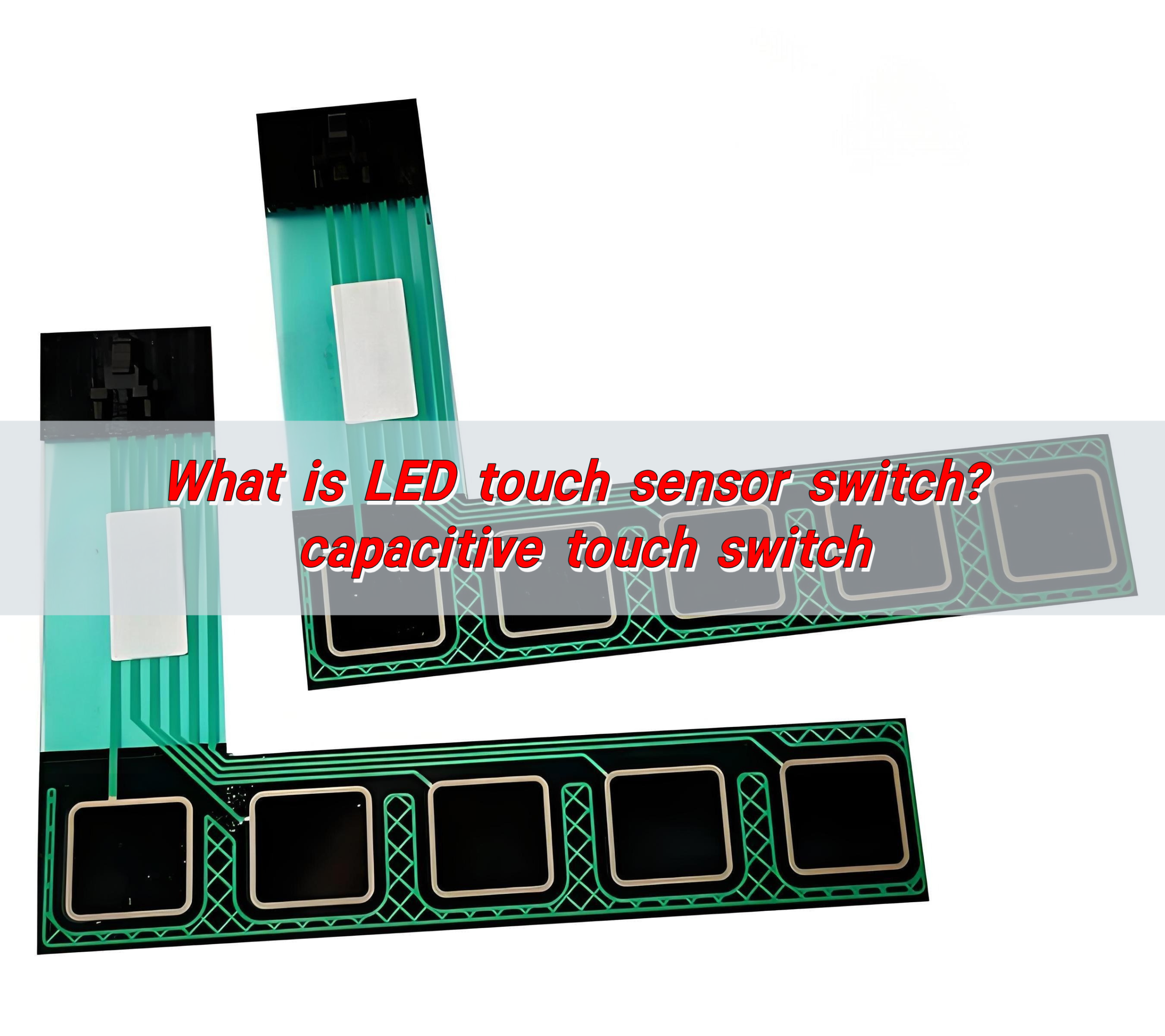

What is LED touch sensor switch? capacitive touch switch

The LED touch sensor switch is an electronic component that combines an LED light and a touch sensor. It controls the on and off of the LED light by touching it, achieving energy-saving and convenient lighting control. It uses capacitive sensing technology to detect human proximity or touch, thereby controlling the on and off of ...

What is IP66 Waterproof? Waterproof Rating of Membrane Switches

The IP66 waterproof rating means that the device is completely protected from dust ingress and can withstand strong water jets. The waterproof rating of membrane switches can usually reach IP67, which is achieved through special processes and materials to ensure its reliability in humid or rainy environments. This performance makes membrane switches suitable for scenes ...

Why are flexible membrane switches a popular choice in modern electronics?

Flexible membrane switches are popular in modern electronic products due to their flexibility, thinness and economy. They not only adapt to complex curved surfaces and achieve flexible design, but also have environmental adaptability such as waterproof and dustproof. In addition, they support multi-function integration, such as LED indicators and sound feedback, to enhance user experience. ...

Contact us online