Electroluminescent Panel Manufacturer | Yuan Electronics

Electroluminescent Panel Manufacturer | Yuan Electronics

Electroluminescent (EL) panels are unique light sources that offer a soft, consistent glow, making them a popular choice in various applications. Whether you’re exploring these panels for creative design, electronics, or signage, it’s essential to understand their features, benefits, and limitations. This guide will break down the core aspects of electroluminescent panels, including their lifespan, voltage, differences from LED panels, how to cut them, and more.

What Are Electroluminescent Panels?

Electroluminescent (EL) panels are flat, flexible panels that emit light when an electric current is passed through them. The panel consists of a thin layer of phosphor material sandwiched between two electrodes. When voltage is applied to the electrodes, the phosphor material emits light. This process is known as electroluminescence. EL panels are available in various colors, including green, blue, and white, and are typically used for backlighting, signage, or decorative purposes.

The key advantage of EL panels is their uniform light output. Unlike LEDs, which often produce concentrated spots of light, EL panels provide a consistent, even glow over a larger surface area. Their thin, flexible nature makes them ideal for use in spaces where traditional light sources would be cumbersome or bulky.

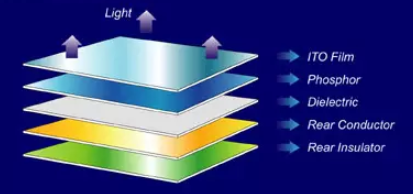

EL Panel Structure

A EL panel is mainly made of an ITO film, dielectric layer, phosphor, conductor and a insulator. Its structure just like below:

What Is the Lifespan of an EL Panel?

The lifespan of an electroluminescent panel depends on several factors, such as the quality of the materials used and the amount of voltage applied. On average, EL panels last between 10,000 to 50,000 hours. The light output tends to fade gradually over time rather than suddenly going dark.

Compared to LED lighting, which generally lasts much longer, EL panels have a shorter lifespan. However, the soft, diffused glow they emit makes them well-suited for applications where longevity is less critical, and aesthetic appeal is more important. Regular use at lower voltage levels can help prolong the life of the panel, ensuring you get the most out of your investment.

What Is the Voltage of Electroluminescent Panels?

Electroluminescent panels typically operate at a low voltage, usually between 90V and 200V AC for standard applications. Some panels, however, can function at higher voltages depending on their size and purpose. The voltage required for a specific EL panel is usually indicated by the manufacturer, so it’s essential to check the specifications before installation.

EL panels require an inverter to convert the standard low voltage DC from your power source into the higher AC voltage needed for the panel to light up. Without an inverter, the panel will not operate correctly.

What Is the Difference Between LED and EL Panels?

While both LED and EL panels are used for lighting applications, they have distinct differences in how they work and their practical applications.

- Light Emission: LEDs emit light in concentrated points, while EL panels provide a soft, uniform glow over a larger surface area.

- Flexibility: EL panels are flexible and can be bent or shaped to fit into various designs, whereas LEDs are rigid and require more space.

- Size and Thickness: EL panels are typically thinner than LED panels, making them ideal for lightweight applications or thin, flexible designs.

- Power Requirements: EL panels typically require higher voltages and an inverter to operate, whereas LEDs usually run on low DC voltage without the need for an inverter.

The choice between EL and LED panels largely depends on the specific needs of the project. EL panels are more suitable for applications that require a consistent, soft light over a large area, while LEDs are better for focused, bright light with more efficient energy consumption.

Can You Cut Electroluminescent Panels?

Yes, one of the great features of electroluminescent panels is that they can be cut to fit specific shapes or sizes. This flexibility allows them to be adapted for various applications, from custom designs in interior decoration to backlighting in electronics. However, there are some important precautions to take when cutting an EL panel:

- Cut Along the Designated Lines: Most EL panels have pre-marked lines where they can be safely cut. Cutting outside of these lines can damage the electrodes or the phosphor layer, rendering the panel unusable.

- Use Proper Tools: Use sharp scissors or a utility knife to ensure clean cuts. Avoid using dull or serrated tools, as these can cause uneven edges or damage the panel.

- Reattach Wires After Cutting: If you need to reconnect the panel after cutting, ensure the electrodes are securely reattached. A soldering iron is usually required for this task.

Cutting EL panels requires care and precision, but it can provide a more tailored solution for your project needs.

How to Make an Electroluminescent Panel

Making an electroluminescent panel involves several key steps and materials. If you’re interested in creating a custom electroluminescent panel, here’s a simplified breakdown:

Materials Needed:

- Electroluminescent phosphor powder

- Transparent conductive film or electrodes

- A flexible backing material

- Inverter (to convert DC to AC voltage)

Steps:

- Prepare the Backing Material: The backing material needs to be flexible and thin. Common materials include plastic or other flexible substrates.

- Apply Conductive Electrodes: Using conductive materials, apply electrodes on both sides of the backing material. This will help carry the electric current to the phosphor layer.

- Apply the Phosphor: Coat the backing with a thin layer of phosphor material. This layer will emit light when electricity is applied.

- Connect the Inverter: Attach the panel to an inverter that will step up the voltage from a power source (typically 12V DC) to the required AC voltage.

While making your own EL panel can be a fun DIY project, it does require precision and knowledge of electronics. If you’re not familiar with handling electrical components, it may be best to purchase pre-made panels.

What Are Electroluminescent Displays Best Used For?

Electroluminescent panels are versatile and can be used in a wide range of applications. Here are some of the most common uses:

- Backlighting: EL panels are frequently used to backlight displays, such as dashboards, instrument panels, and other electronic devices.

- Signage: Their soft, glowing light makes EL panels a popular choice for illuminated signage and advertising. Custom electroluminescent panels can be designed for unique, eye-catching signage.

- Decorative Lighting: Many artists and designers use EL panels in creative ways, from lighting up artwork to creating illuminated decor for events.

- Wearable Technology: EL panels’ flexibility allows them to be incorporated into wearable tech, such as LED clothing, costumes, or safety vests.

- Emergency Lighting: Due to their soft, continuous glow, EL panels are sometimes used as emergency lights or exit signs.

Electroluminescent panels are an innovative and versatile lighting solution with numerous applications. Whether you’re looking to use them for backlighting, signage, or custom designs, they offer a unique glow that cannot be achieved with traditional light sources like LEDs. While they may have a shorter lifespan than LEDs and require higher voltage to operate, their ability to be cut into custom shapes and provide an even, soft light makes them an attractive option for many projects. If you need a reliable electroluminescent panel manufacturer, welcome to contact us, we are the experts in this industry.

Transforming Human-Machine Interfaces with Innovative Membrane Switch Solutions

In the fast-evolving world of electronic controls and user interfaces, Shenzhen Yu An Electronics Co., Ltd stands out as a leader in membrane switch design and manufacturing. Founded in 2006 in Shenzhen, China, Yu An Electronics has grown into a trusted provider of high-quality membrane switches and related products that serve diverse industries—from medical and ...

Practical Comparison between Mechanical Buttons and Membrane-Based Control Systems

Modern electronic devices are heavily dependent on the user input system, and the selection of an appropriate control interface has an impact on durability, usability, and maintenance. Understanding the disparity between the old mechanical type and membrane-based controls will help designers and purchasers make decisions based on the information. How Mechanical Buttons Work Mechanical buttons ...

Know the Difference between Tactile and Non-Tactile Membrane Switching

When selecting the appropriate interface for a product, it can be wise to understand the differences between tactile and non-tactile membrane switches so that the engineer and the purchaser make a better decision. They are both very common in medical equipment, domestic appliances, and industrial equipment, though they do not present the same user experience. ...

Contact us online