How are membrane switches made?

How are membrane switches made?

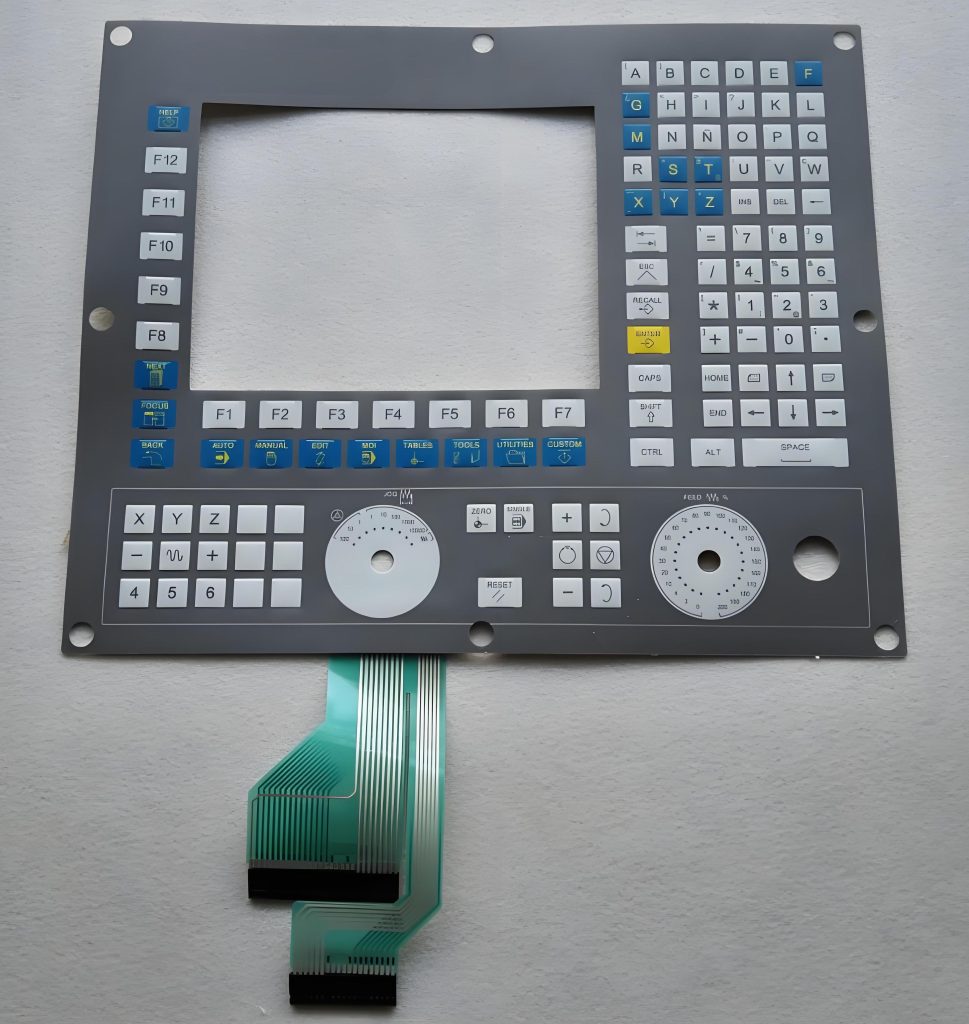

There are several main steps in the production of membrane switches. First, design and plate making are carried out, design drawings are drawn and printed plates are made; then materials are prepared, such as membrane materials, conductive materials and metal dome switches; then printing and production are carried out, including panel layer printing, circuit layer production, metal dome switch installation, isolation layer and adhesive layer production; finally, testing and packaging are carried out to ensure the appearance, electrical performance and key feel are good before packaging.

With rich experience and growing market demand, Yu An Electronics has transformed its business into a comprehensive one-stop service provider for tactile membrane switches, capable of customizing membrane switches of various shapes, sizes and functions according to the specific needs of customers.

What material is a membrane switch made of?

Membrane switches are mainly made of the following materials:

- 1. Polycarbonate (PC): Polycarbonate film has excellent temperature resistance and mechanical properties, a wide temperature resistance range (-30℃ to 130℃), good impact resistance and high elasticity. In addition, polycarbonate film can maintain stable performance when temperature or humidity changes, and is suitable for various harsh environments.

- 2. Polyester (PET): Polyester film has good switch life, excellent corrosion resistance and wear resistance, and excellent insulation performance. Although the price is slightly higher than PC, its temperature resistance and mechanical properties are also quite excellent, suitable for instruments and home appliance panels with higher requirements.

- 3. Polyvinyl chloride (PVC): Polyvinyl chloride film is cheap, has excellent chemical corrosion resistance and insulation performance, but its temperature resistance is poor. It generally softens at around 60°C, and has poor tensile and wear resistance. It is suitable for sign panels and is not suitable for membrane switches.

How are membrane switches made?

The production process of membrane switches mainly includes the following steps:

Draw the panel diagram and FPC circuit diagram: First, you need to use design software to draw the panel and FPC circuit diagram. After the panel design is completed, stick the pot piece to the corresponding pad, and then prepare the panel’s protective film and adhesive.

Assembly process: stick the pot piece to the corresponding pad with tape, tear off the protective film of the panel and the oil paper with adhesive backing, match the panel with adhesive backing to the FPC, and then stick them together. If there is an isolation layer, put it on the pot piece and stick it to the top panel.

Are membrane switches mechanical?

A membrane switch is not a mechanical switch, but an electronic switch.

A membrane switch is a micro switch device made of film material, which consists of four parts: panel, upper circuit, isolation layer, and lower circuit.

It controls the connection and disconnection of the circuit through pressure sensing. When the corresponding pressure is applied from the outside, the film produces a slight bending deformation, so that the electricity contacts or separates each other, thereby realizing the switch control of the circuit.

Membrane switches have the characteristics of small size, light weight, long service life, waterproof and moisture-proof, so they have been widely used in electronic products, instruments, home appliances and other fields.

In contrast, mechanical switches are mainly composed of mechanical parts, including buttons, springs and contacts, etc. The contact points are opened or closed by mechanical force to control the on and off of the current. And metal materials are usually used as contact points to ensure the smooth passage of current.

In general, membrane switches and mechanical switches have their own characteristics and applicable scenarios. Membrane switches are suitable for occasions that require light touch operation, while mechanical switches are suitable for occasions that require greater operating force or longer travel.

What are the parts of a membrane switch?

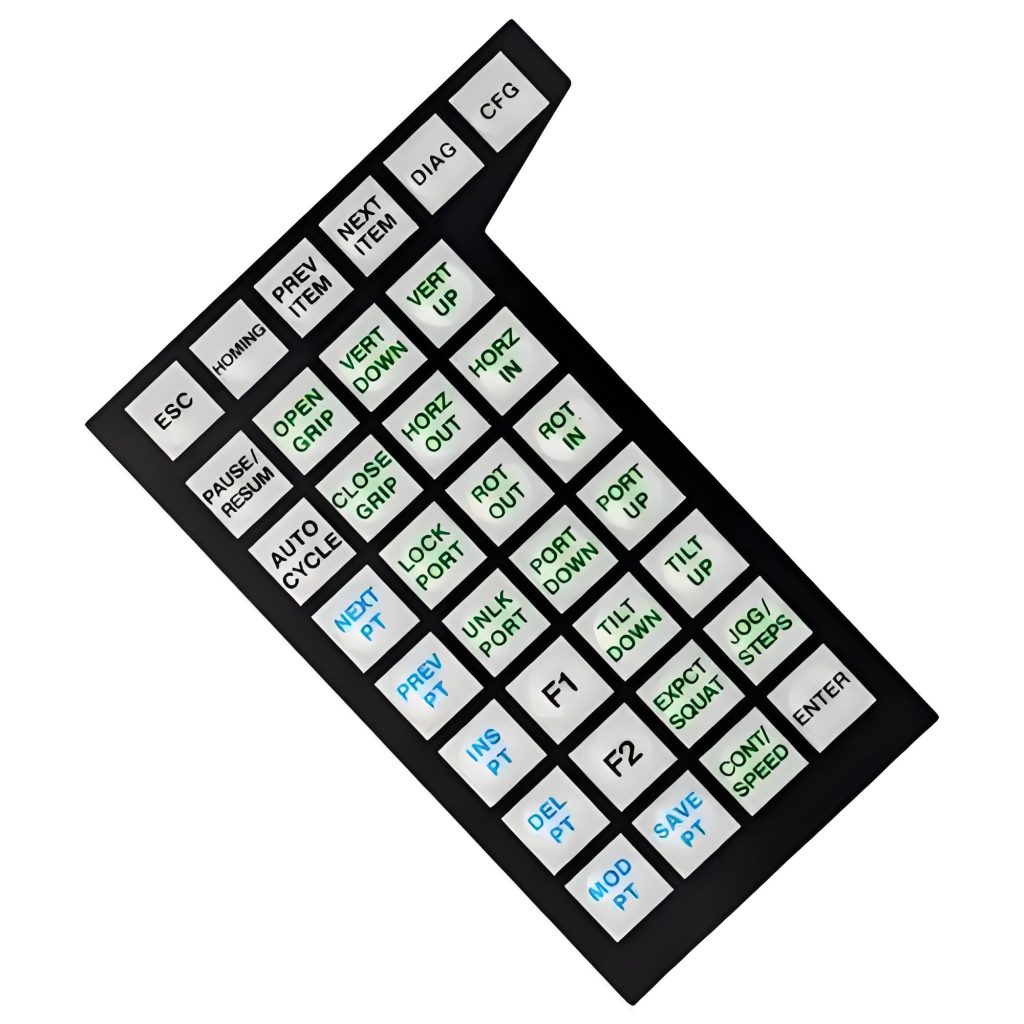

Membrane switches are mainly composed of the following parts:

- Panel: It plays a role of identification and decoration through different colors, patterns and button shapes. The panel material needs to have the characteristics of high transparency, high ink adhesion, high elasticity, and anti-folding.

- Upper circuit and lower circuit: The upper circuit and lower circuit are the electrical components of the membrane switch, responsible for the contact function of the switch. They are usually formed by printing conductive materials on the film, the most common of which is PET material.

- Surface glue, isolation layer, bottom glue: These three layers are double-sided adhesives, which are used to fix and isolate the layers. Their thickness is determined by the thickness of the switch and the key operation force.

How do membrane switches work?

When the button is not pressed, the conductive circuit of the circuit layer is in a disconnected state and no current passes. At this point, the membrane switch is in its initial state, waiting for the user’s operation.

When the user presses the button on the membrane switch, the panel layer at the button will sink downward, squeezing the isolation layer and the circuit layer. The conductive circuit in the circuit layer deforms under the action of pressure, so that the originally disconnected conductive circuits are connected together to form a closed circuit. Current will flow through the closed circuit, generating an electrical signal. This electrical signal will be transmitted to the control system of the electronic device connected to it.

After the user releases the button, the panel layer, isolation layer and circuit layer will return to their original state under the action of their own elasticity. The conductive circuit of the circuit layer is disconnected again, the current stops flowing, and the electrical signal disappears.

How long do membrane switches last?

The service life of a membrane switch is usually more than 1 million times. Specifically, the life of a membrane switch is generally between 100,000 and 1 million times, and the specific value depends on its material quality, design rationality and manufacturing process level.

Factors affecting the life of a membrane switch

- Material quality: high-quality base materials, conductive materials and panel materials can provide good elasticity and durability, ensuring that the switch maintains stable performance during long-term use.

- Design rationality: Reasonable key structure design, sealing design and layout design can reduce the possibility of mechanical wear and failure, maintain performance stability and extend service life.

- Manufacturing process level: High-level manufacturing process can ensure the accuracy and consistency of the switch, reduce defects and hidden dangers in the production process, and thus improve the overall life.

Are membrane switches good?

Membrane switches have many advantages, which make them perform well in many fields and are widely used in various devices.

- High flexibility in appearance design: Membrane switches can be made in various colors, patterns and fonts according to needs to meet the appearance design requirements of different products, making the products more visually attractive and unique.

- Comfortable operation feel: The buttons of membrane switches are usually designed with a certain elasticity and travel, moderate pressing force, comfortable operation feel, and good user experience.

- Strong functional reliability: Using high-quality materials and advanced manufacturing technology, it has high mechanical strength and wear resistance, long service life, and generally can reach hundreds of thousands or even millions of operations.

- Good environmental resistance: It has good waterproof, dustproof, moisture-proof, corrosion-resistant and other properties, and can work normally under various harsh environmental conditions.

- Small size and light weight: The membrane switch itself is thin and light, which will not add too much volume and weight to the equipment, which is conducive to the miniaturization and lightweight design of the product.

- Low cost: The production cost of membrane switches is relatively low, which is suitable for large-scale production.

Membrane switches are widely used in electronic communications, electronic measuring instruments, industrial control, medical equipment, automotive industry, smart toys, household appliances and other fields.

In summary, membrane switches are indeed a very practical electronic component due to their many advantages and wide application fields.

In short, membrane switches are an electronic component with broad application prospects, and metal dome switches, as a key component of membrane switches, have important functions such as providing a good key feel, improving the reliability and life of membrane switches, and realizing multi-functional key design.

What is a Membrane Switch Panel? A Complete Guide

Membrane switch panel is a thin, beautiful electronic component that integrates key functions, indicator components and instrument panels. It consists of a panel, an upper circuit, an isolation layer and a lower circuit. When pressed, the upper circuit contacts and the lower circuit are connected. When released, the contact rebounds and the circuit is disconnected. ...

Custom Silicone Rubber Membrane Switch & Rubber Keypad

Silicone rubber membrane switch is a membrane switch made of silicone rubber material, which has the advantages of silent operation, high temperature resistance and stable chemical properties. It changes the structure of the traditional touch switch using metal shrapnel and uses silicone rubber as the conductive material, so it is also called a silent touch ...

Why choose a PET membrane switch? Key benefits you should know

PET membrane switches have good key life, corrosion resistance, wear resistance, and excellent insulation performance, and are suitable for key parts that are used frequently. They have high hardness and can withstand large key forces, ensuring long-term stability. In addition, PET membrane switches have good temperature resistance and can operate in a temperature range of ...

Contact us online