How to make a membrane switch?

How to make a membrane switch?

In modern electronic devices, membrane switches are widely used for their thinness, beauty and durability. From household appliances to industrial control equipment, from medical instruments to communication products, membrane switches are everywhere. So, how to make membrane switches?

How are membrane switches made?

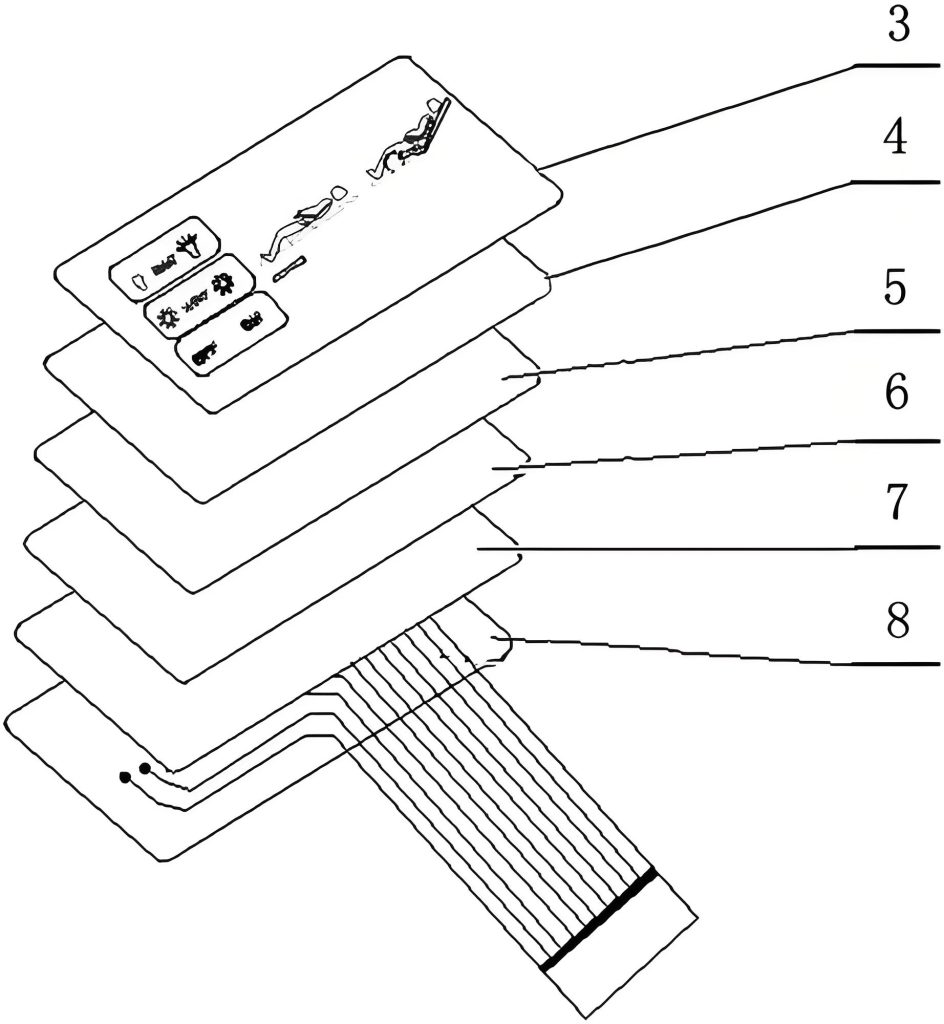

The production process of membrane switches mainly includes the following steps:

- Electrode plate processing: First, the electrode plate is processed to ensure that its surface is clean and flat for subsequent printing and assembly.

- Make a screen printing plate: Make a screen printing plate according to the design requirements, which is a template for transferring ink during the printing process.

- Screen printing silver paste: Print silver paste on the electrode plate to form a conductive circuit. This step requires ensuring that the silver paste is evenly covered and thoroughly dried.

- Drying: Put the electrode plate printed with silver paste into an oven for baking, usually at a temperature of 115 degrees Celsius, for 40 minutes to ensure that the silver paste is completely dry.

- Stamping: The electrode plate is stamped to form the required switch structure and contact shape.

- Screen-printed panel: The panel material is screen-printed on the electrode plate, usually a protective film or decorative layer to increase the beauty and durability of the switch.

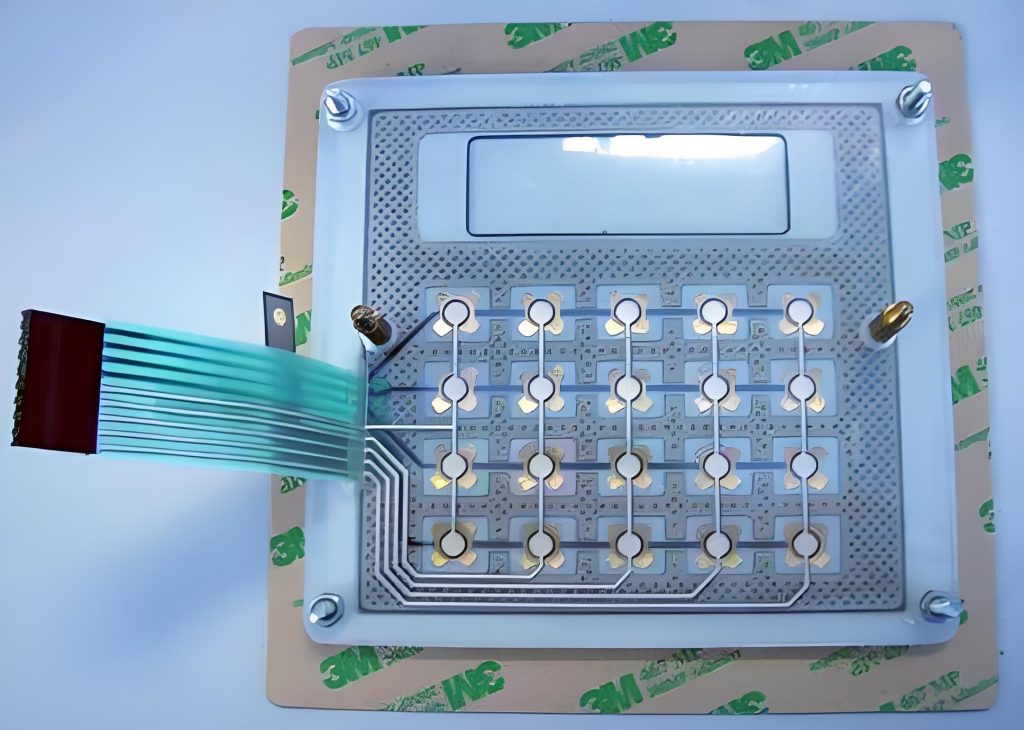

- Assembly: Assemble the various components together to form a complete membrane switch. Circuit testing is required during the assembly process to ensure that there are no problems such as short circuits and open circuits.

Classification and application scenarios of membrane switches:

- According to the circuit substrate: divided into flexible boards and rigid boards.

- According to the panel shape: divided into flat and three-dimensional types.

- According to the operating feel: divided into non-sensing and sensing types.

- According to special uses: including transparent and finger-touch membrane screen types.

- According to the combination method: divided into panel and discrete parts and keycaps and keyboards.

What material is a membrane switch made of?

Membrane switches are mainly made of the following materials:

- Conductive film: The conductive film is the core component of the membrane switch, and is usually printed on the film using conductive paste to form a contact circuit. The main component of the conductive paste is metallic silver, and the size and shape of its particles determine the resistance of the switch circuit.

- Insulating film: The insulating film is used to isolate the conductive film to prevent the circuit from short circuiting. Common insulating film materials include polycarbonate (PC), polyester (PET) and polyvinyl chloride (PVC).

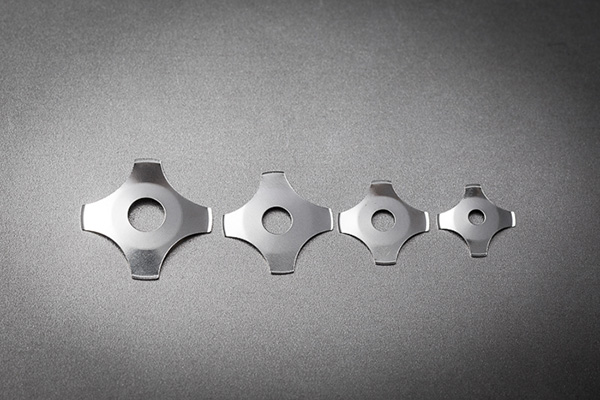

- Metal dome: Metal dome provides elasticity and structural support for membrane switches. Thin sheet-like components made of metal materials (such as stainless steel, copper, etc.) have excellent elasticity and conductivity

- Panel material: Panel material is usually a plastic film printed with colorful decorative patterns. Commonly used materials are polycarbonate (PC), polyester (PET) and polyvinyl chloride (PVC).

Are membrane switches clicky?

The membrane switch will make a clicking sound when pressed. This sound is usually a mechanical sound caused by the deformation and rebound of the dome of the membrane switch when pressed. This sound is normal, but if the sound is too loud or insensitive, it may be caused by poor oxidation contact of the dome.

The working principle of the membrane switch is that when pressed, the contact of the upper circuit is deformed and connected with the plate of the lower circuit. After the finger is released, the contact rebounds back, the circuit is disconnected, and a signal is triggered.

This design enables the membrane switch to have appropriate press recovery elasticity, and the adjacent sheet keys cannot be linked when pressed, ensuring the stability and reliability of use.

What is an example of a membrane switch?

Examples of membrane switches include pot pieces, touch switches, membrane key switches, etc. These products are usually composed of metal dome, plastic shell and circuit board, with the characteristics of waterproof, dustproof, high temperature resistance, etc., and are widely used in various electronic devices.

- 1. Pot piece: This is a common membrane switch, usually used in the key part of mobile phones, remote controls and other devices. The pot piece is composed of metal dome and plastic shell, has the function of touch switch, is easy to use and durable.

- 2. Touch switch: This switch is widely used in various electronic devices, such as mobile phones, computers, etc. The touch switch has the characteristics of waterproof and dustproof, and is suitable for various harsh environments.

- 3. Membrane key switch: This switch is usually used in home appliances, industrial control and other fields, with the characteristics of simple operation and long service life.

The manufacturing process of membrane switches includes steps such as printing silver paste and bonding circuit boards. In terms of materials, common ones are metal dome, plastic shell and circuit board. Metal dome is usually made of stainless steel or gold-plated materials to ensure the durability and conductivity of the switch.

How long do membrane switches last?

The service life of membrane switches can usually reach hundreds of thousands to millions of times, which is specifically affected by the following factors:

- 1. Film material: For example, PET materials have good elasticity and temperature resistance, and have a long service life under normal conditions; PC materials are slightly weaker in some properties.

- 2. Printing process: Poor printing quality will cause circuit problems, reduce performance and life.

- 3. Lamination process: If the layers are not firmly bonded, delamination and blistering will occur, affecting the life.

- 4. Temperature: High temperature accelerates aging, and low temperature makes the film brittle; both have adverse effects on life.

- 5. Humidity: High humidity can easily lead to short circuits and corrosion, and dry environments can easily generate static electricity to damage switches.

- 6. Dust and chemicals: Dust affects work, and chemicals can corrode the film and contacts, shortening the life.

- 7. Pressing force: Too much pressure can easily deform the structure and damage the contacts, and too little pressure may not trigger.

- 8. Pressing frequency: Frequent pressing will accelerate wear and aging.

Can membrane keyboards have switches?

Membrane keyboards do have switches, but they work differently than mechanical keyboards.

The switch mechanism of a membrane keyboard is achieved through a layer of membrane. Specifically, a membrane keyboard usually consists of two layers of membrane, upper and lower, which come into contact when a key is pressed, generating an electrical signal. This switch mechanism makes membrane keyboards light, thin, and inexpensive, but they have a mediocre feel and less noise.

The switch mechanism of a membrane keyboard is significantly different from the mechanical switch of a mechanical keyboard. Each key of a mechanical keyboard has an independent mechanical shaft, which moves downward when the key is pressed, generating an electrical signal in contact with the circuit board. This design gives the mechanical keyboard a better feel and durability.

In general, the switch mechanism of a membrane keyboard is to achieve the transmission of electrical signals through membrane contact, while the switch mechanism of a mechanical keyboard is to achieve the transmission of electrical signals through the physical movement of the mechanical shaft. The two mechanisms differ in feel, durability, and price.

In short, metal domes play a vital role in the production of membrane switches. By properly selecting the material and size of the metal dome, and correctly installing and using the metal dome, the performance and quality of the membrane switch can be improved, providing users with a better operating experience.

Custom Silicone Rubber Membrane Switch & Rubber Keypad

Silicone rubber membrane switch is a membrane switch made of silicone rubber material, which has the advantages of silent operation, high temperature resistance and stable chemical properties. It changes the structure of the traditional touch switch using metal shrapnel and uses silicone rubber as the conductive material, so it is also called a silent touch ...

Why choose a PET membrane switch? Key benefits you should know

PET membrane switches have good key life, corrosion resistance, wear resistance, and excellent insulation performance, and are suitable for key parts that are used frequently. They have high hardness and can withstand large key forces, ensuring long-term stability. In addition, PET membrane switches have good temperature resistance and can operate in a temperature range of ...

What is a PCB Membrane Switch? PCB Switch Types

PCB membrane switch is a switch based on rigid circuit board, suitable for application scenarios that require stronger mechanical stability and reliability. It is usually composed of multiple layers of film, including conductive film, circuit breaker film and display film, etc., and the circuit is turned on and off by touch or press operation. The ...

Contact us online