What is a membrane switch?

What is a membrane switch?

A membrane switch is an input device widely used in electronic devices. It is made of a composite of multiple layers of thin film materials. Its basic structure includes a panel, a circuit, and adhesive. The membrane switch presses a specific area to turn on the circuit, thereby realizing signal transmission, completing operations such as turning the machine on and off, and adjusting parameters. It plays a key role in many fields from home appliances to industrial control.

How does a membrane switch work?

The working principle of a membrane switch is based on the pressure sensing and changes of thin film resistors. When there is no external pressure, the thin film resistor patch is in a flat state, and the gap between the contacts is large, so that the current cannot pass through, and the switch is in an open state.

When external pressure is applied or the membrane is touched, the metal shrapnel will deform, the gap between the contacts will become smaller, and the resistance between the conductive materials will decrease, so that the current can pass through and the switch will close.

When the external pressure disappears, the metal shrapnel will return to its original shape, the gap between the contacts will be restored, the resistance between the conductive materials will increase, the current cannot pass through, and the switch will be disconnected.

What are the parts of a membrane switch?

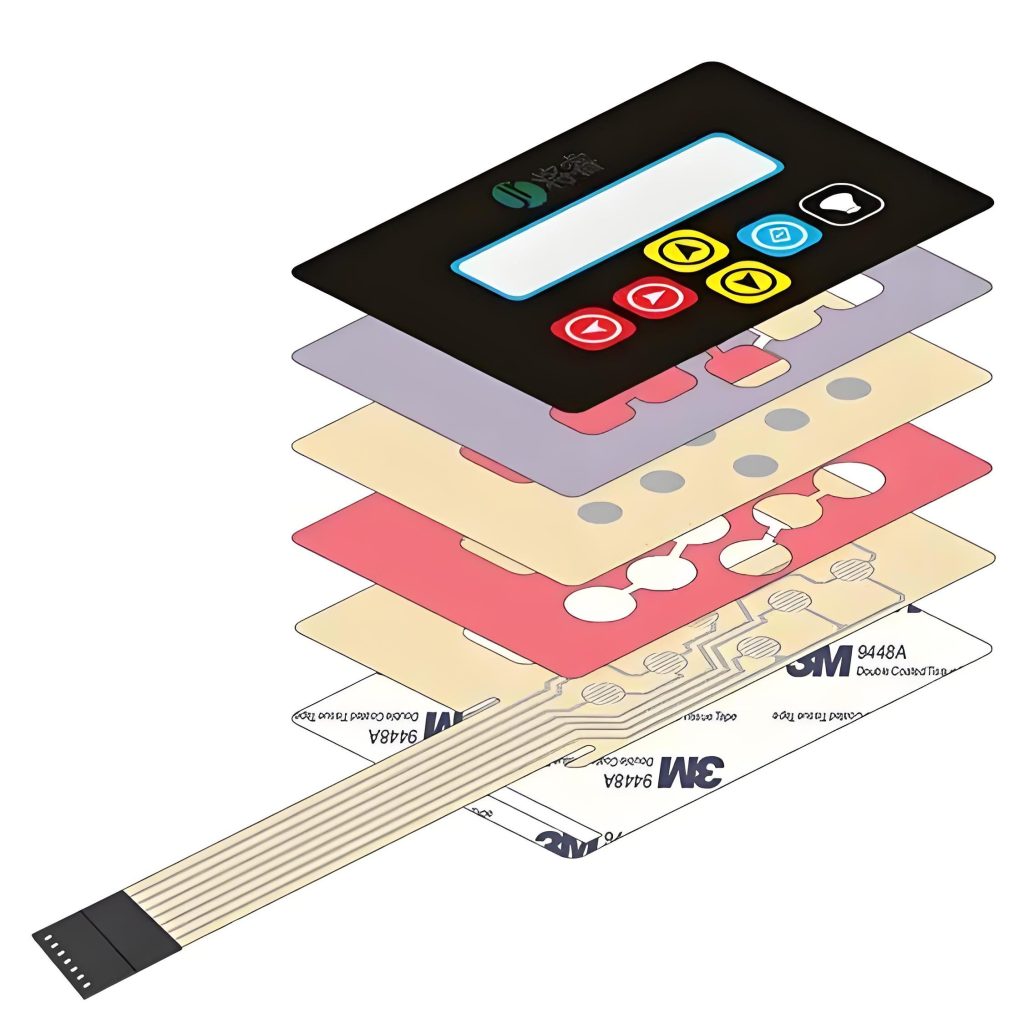

Membrane switches are mainly composed of the following parts:

- Panel: The panel of a membrane switch is usually composed of a rigid or flexible printed circuit board, with buttons with or without touch installed on it, and covered with a plastic film (such as polycarbonate PC, polyester PET, etc.) printed with colorful decorative patterns.

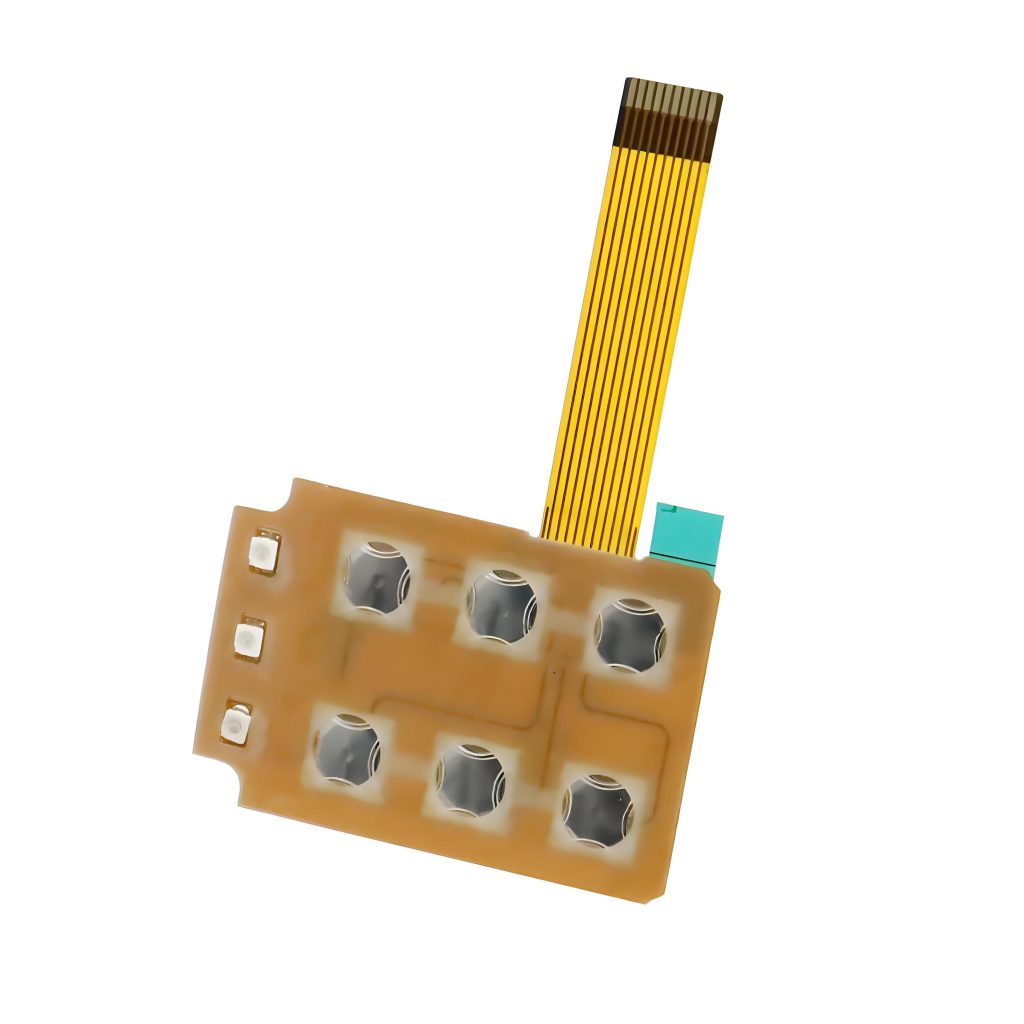

- Upper circuit: Installed on the panel, usually composed of a conductive film. When the panel is pressed, the contacts of the upper circuit will deform and contact the lower circuit, thereby conducting the circuit.

- Isolation layer: Located between the upper circuit and the lower circuit, it plays an insulating and protective role to prevent the upper circuit and the lower circuit from directly contacting each other and causing a short circuit.

- Lower circuit: Corresponding to the upper circuit, when the upper circuit is deformed by pressure, the contacts of the lower circuit will be triggered to complete the conduction of the circuit.

- Base glue: Located at the bottom layer of the membrane switch, it plays a role in fixing and protecting the entire structure.

Where are membrane switches used?

- Electronic communications: Membrane switches are used in these fields to provide a user-friendly operating interface, which is convenient for various settings and adjustments.

- Industrial control: In industrial automation equipment, membrane switches are used to control the start and stop of various mechanical and electronic equipment, providing an intuitive operating interface.

- Medical equipment: In the medical field, membrane switches are used to control the operation of various medical equipment to ensure that medical staff can conveniently perform various medical operations.

- Automotive industry: In automobiles, membrane switches are used to control various functions in the car, such as air conditioning, audio, etc., providing a convenient operating experience.

- Smart toys and household appliances: In these fields, membrane switches are used to control various functions of toys and household appliances, provide an intuitive operating interface, and have the characteristics of beauty and durability.

Are membrane switches good?

Membrane switches perform well in many aspects and have many advantages.

First of all, membrane switches are flexible and thin, suitable for small and light electronic products, easy to carry and disassemble.

In addition, membrane switches have low production costs, which are cheaper than mechanical switches, and have higher reliability. High durability, can withstand a certain degree of pressure and impact, and have a long service life.

Membrane switches are also waterproof, dustproof, oil-proof, and resistant to harmful gas erosion. They have strong sealing properties and can work stably in harsh environments. They have beautiful appearance and can be made into various patterns through modern silk-screen technology to enhance the aesthetics of the product.

Membrane switches have excellent conductivity and are printed with carbon paste, silver paste, copper platinum, etc. The resistance is adjustable and they can withstand high-voltage electric shocks without damaging their functions.

How long do membrane switches last?

The service life of membrane switches is usually more than 1 million times. The life of a membrane switch mainly depends on its material quality, design rationality, and manufacturing process level.

Factors affecting the life of a membrane switch

- Material quality: High-quality base materials can provide good elasticity and durability. The conductivity and corrosion resistance of conductive materials also directly affect the reliability and life of the switch.

- Design rationality: Reasonable key structure design can reduce the possibility of mechanical wear and failure, the sealing design prevents the intrusion of external pollutants, and the layout design reduces misoperation, thereby extending the service life.

- Manufacturing process level: High-level manufacturing process can ensure the accuracy and consistency of the switch and reduce defects and hidden dangers in the production process, including printing process, laminating process and quality control.

Methods to extend the life of membrane switches

- Select high-quality materials: Use high-quality substrate materials and conductive materials to ensure that the switch maintains stable performance during long-term use.

- Optimize design: Reasonably design the key structure, seal and layout to reduce the possibility of mechanical wear and failure and prevent external contaminants from invading.

- Improve the manufacturing process level: Exquisite printing process, laminating process and strict quality control to ensure the stability and reliability of each production link.

What is the difference between a membrane switch and a mechanical switch?

There are significant differences between membrane switches and mechanical switches in terms of working principles, structural characteristics, application scenarios, etc.

1. Working principle

- Membrane switch: The membrane switch realizes signal transmission through the contact between the metal shrapnel and the conductive material. When the membrane switch is touched or lightly pressed, the protruding part on the circuit board under the transparent film contacts the metal shrapnel. Due to the elastic deformation of the metal, the resistance value between the two contact points changes, thereby generating a switch action.

- Mechanical switch: The mechanical switch uses physical force to rotate the switch or button, gradually contacting the conductive terminal or disconnecting the circuit to achieve the purpose of switching power or changing the current voltage.

2. Structural characteristics

- Membrane switch: The membrane switch is thin, light and flexible. Its structure includes transparent film, circuit board, metal shrapnel and other components. It has high reliability, light weight, small thickness, beautiful appearance, and can be processed into various specifications and shapes.

- Mechanical switch: The structure of the mechanical switch is relatively complex and is usually composed of metal parts, including the front cover, baffle, terminal board and back cover. Its structure is relatively solid and can withstand large mechanical loads and vibrations.

3. Application scenarios

- Membrane switch: It is widely used in home appliances, electronic instruments, mechanical equipment and other fields. Due to its beautiful appearance, simple structure and flexible installation, it is often used in small electronic products such as mobile phones, MP3, tablet computers, etc.

- Mechanical switch: It is often used in automobiles, machine tools, household appliances and other fields. Its operation force is large, and it is suitable for occasions where manual frequent switching or cutting off of power supply is required, such as car steering wheel switches, gas conditioning switches, etc.

What is the difference between a tactile switch and a membrane switch?

There are significant differences between tactile switches and membrane switches in terms of function, structure and application scenarios.

1. Function and structure

- Tactile switch: A tactile switch is an electronic switch that is mainly switched on and off by changing the force of a metal spring. When in use, lightly tap the switch button to turn on the switch, and the switch is disconnected when you release your hand.

- Membrane switch: A membrane switch is also called a touch-type keyboard. When the membrane switch is pressed, the contact of the upper circuit deforms downward and contacts the plate of the lower circuit to conduct. When the finger is released, the contact rebounds and the circuit is disconnected.

2. Application scenarios

- Tactile switch: Tactile switches usually need to be used in conjunction with PCB circuit boards and are suitable for application scenarios that require standard parts size and a single color.

- Membrane switch: Membrane switches are widely used in electronic communications, electronic measurement, industrial control, medical equipment, automotive industry, smart toys, household appliances and other fields.

3. Production process

- Tactile switch: The production process includes stamping, injection molding, cleaning, assembly, molding, inspection and other processes.

- Membrane switch: The production process includes silk screen printing, die cutting, assembly, testing and other processes.

In short, as an advanced electronic component, the membrane switch plays an important role in the field of modern science and technology with its multi-layer structure and exquisite design. As a key component, the metal dome gives the membrane switch reliable tactile feedback, stable electrical connection and excellent durability.

Why choose a PET membrane switch? Key benefits you should know

PET membrane switches have good key life, corrosion resistance, wear resistance, and excellent insulation performance, and are suitable for key parts that are used frequently. They have high hardness and can withstand large key forces, ensuring long-term stability. In addition, PET membrane switches have good temperature resistance and can operate in a temperature range of ...

What is a PCB Membrane Switch? PCB Switch Types

PCB membrane switch is a switch based on rigid circuit board, suitable for application scenarios that require stronger mechanical stability and reliability. It is usually composed of multiple layers of film, including conductive film, circuit breaker film and display film, etc., and the circuit is turned on and off by touch or press operation. The ...

What is LGF Membrane Switch? Backlit Membrane Switch

LGF membrane switch is a membrane switch that uses light guide film technology, which can achieve uniform light emission and good visual effects. LGF membrane switches are usually composed of multiple layers of film, including conductive film, circuit breaker film and display film, etc., and the circuit is turned on and off by touch or ...

Contact us online