The Fundamental Aspects of Membrane Touch Panels That You Must Consider

The Fundamental Aspects of Membrane Touch Panels That You Must Consider

The electronic essentials, otherwise called membrane switches or touch switches, are urgent parts of different electronic gadgets and modern control frameworks. These items work with passing electrical on/off capabilities and initiating and deactivating circuits through a push-to-close system. A distinctive trait is their prompt re-visitation of an open state upon discharge, making them appropriate for different applications across ventures.

Development of certified products by a top manufacturer

No matter what their stylish varieties, membrane touch switches share a key development containing a few fundamental parts:

1. Graphic Overlay: Situated as the highest membrane, the realistic overlay of the membrane touch control panel fills in as the connection point for client communication, showing images or directions.

2. Graphic Adhesive: This membrane ties down the realistic overlay to the hidden parts, guaranteeing solidness and life span.

3. Top Circuitry: Comprising printed silver or carbon ink on a polyester membrane, the top hardware works with electrical conductivity and responsiveness to touch inputs.

4. Spacer Adhesive: Set between the top and base hardware membranes, the spacer glue keeps up with the switch’s underlying honesty while permitting adaptability during activity.

5. Bottom Circuitry: Like the top hardware, this membrane adds to electrical availability and switch usefulness to the membrane keypad with LED.

6. Backer Adhesive: Guaranteeing attachment to the unbending help membrane, the supporter glue gives security to the switch gathering.

7. Rigid Backing Membrane: Filling in as the foundation of the switch, this membrane upgrades solidness and primary respectability.

The Essential Highlights of the items

The materials utilized in assembling membrane touch switches fundamentally impact their presentation and attributes. Typical elements of these switches include:

1. High Conductivity: Empowered by materials, for example, silver and carbon, membrane touch switches guarantee proficient electrical conductivity for consistent activity.

2. Flexibility: Using adaptable materials like polyester permits membrane touch changes to adjust to different shapes and arrangements, obliging assorted plan necessities.

3. Strong Adhesion: Glue membranes inside the switch gathering give powerful holding, guaranteeing long-haul strength and protection from ecological elements.

4. Fast Curing: Fast restoring processes upgrade fabricating effectiveness, empowering the quick creation of membrane touch switches without compromising quality.

5. High Reliability: Designed for unwavering quality, membrane touch switches convey steady execution over overstretched periods, limiting free time and support prerequisites.

The various product categories

Membrane touch switches are extensively classified into two sorts: material and non-material, each taking care of explicit application needs:

1. Tactile Membrane Touch Switches: These switches offer material criticism, giving clients a particular sensation upon enactment. The material reaction is often accomplished through arch embellishing or discrete steel vaults, making them reasonable for applications requiring exact info acknowledgment.

2. Non-material Membrane Touch Switches: Intended for solidness and unwavering quality, non-material switches include strong development and complete fixing against outside components. While lacking material input, they consolidate sound and visual pointers to flag actuation, guaranteeing client mindfulness. Non-material switches succeed in requesting conditions and deal with stretched-out life expectancy contrasted with material partners.

Wrapping Up

The products are critical in current electronic gadgets and control frameworks, offering solid execution and flexible usefulness. Understanding the central parts of membrane touch panels, including their development, primary elements, and types, is fundamental for planning proficient and easy-to-use interfaces across different ventures. By considering these elements, specialists and makers can enhance the plan and usefulness of membrane touch changes to meet assorted application prerequisites with accuracy and unwavering quality.

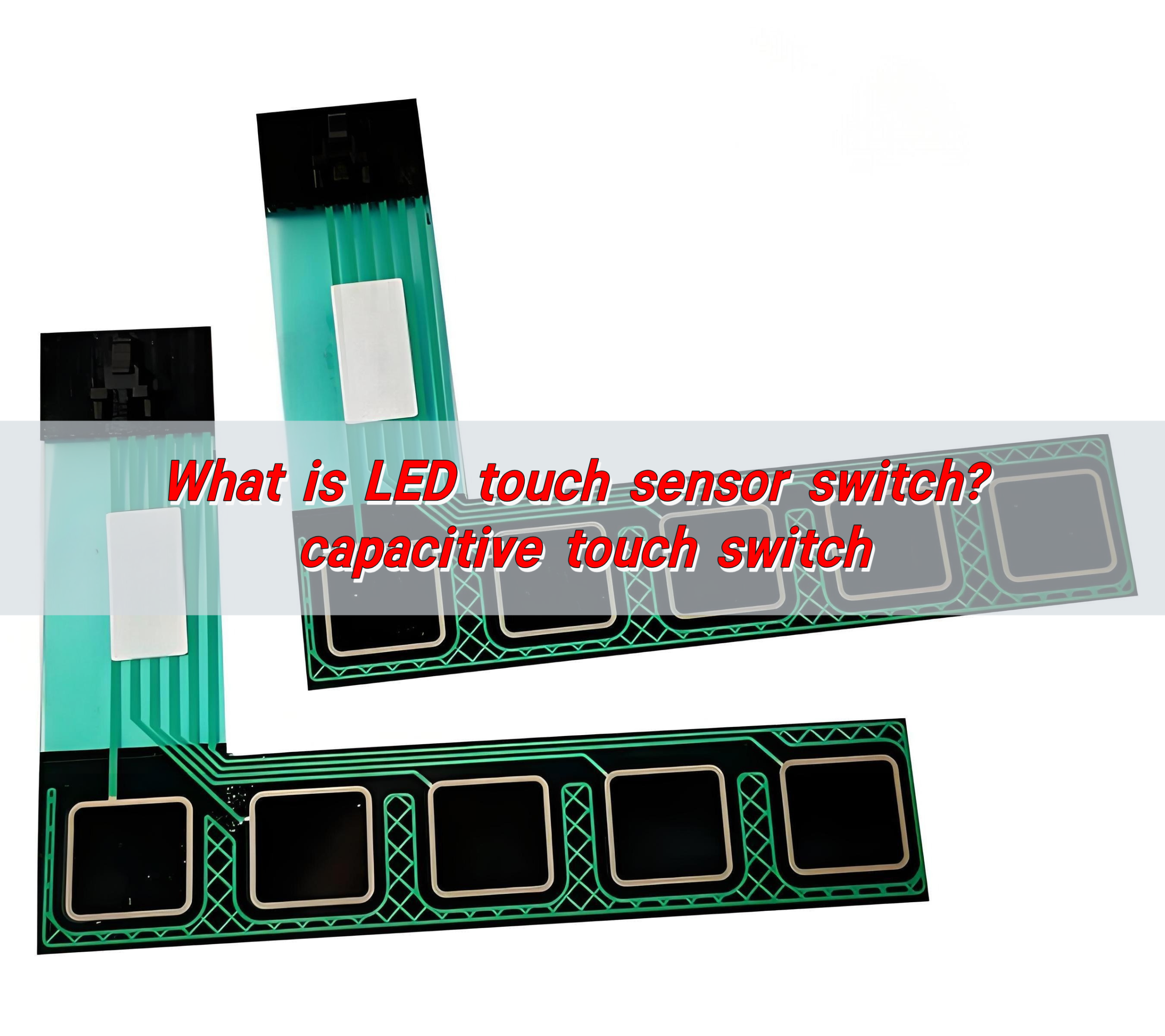

What is LED touch sensor switch? capacitive touch switch

The LED touch sensor switch is an electronic component that combines an LED light and a touch sensor. It controls the on and off of the LED light by touching it, achieving energy-saving and convenient lighting control. It uses capacitive sensing technology to detect human proximity or touch, thereby controlling the on and off of ...

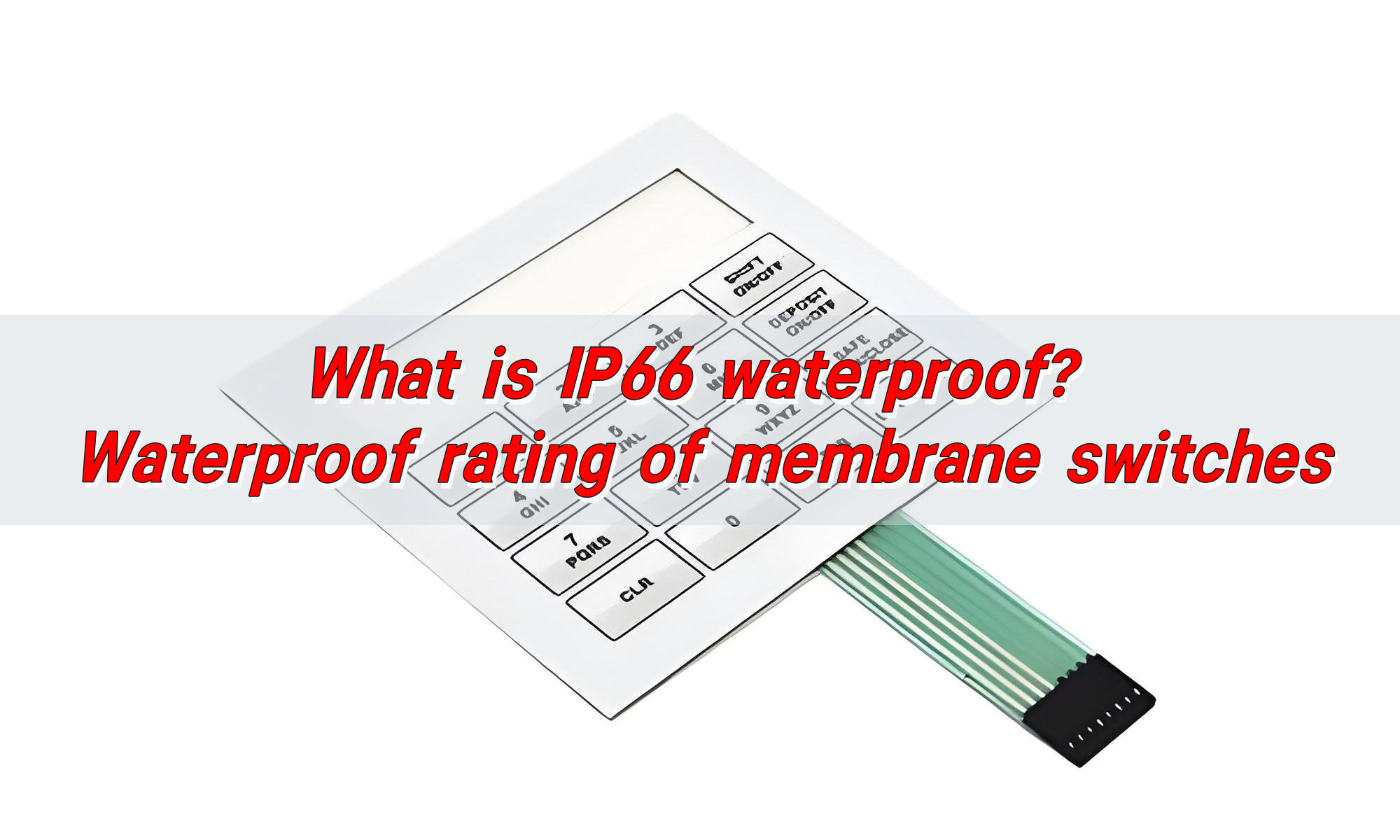

What is IP66 Waterproof? Waterproof Rating of Membrane Switches

The IP66 waterproof rating means that the device is completely protected from dust ingress and can withstand strong water jets. The waterproof rating of membrane switches can usually reach IP67, which is achieved through special processes and materials to ensure its reliability in humid or rainy environments. This performance makes membrane switches suitable for scenes ...

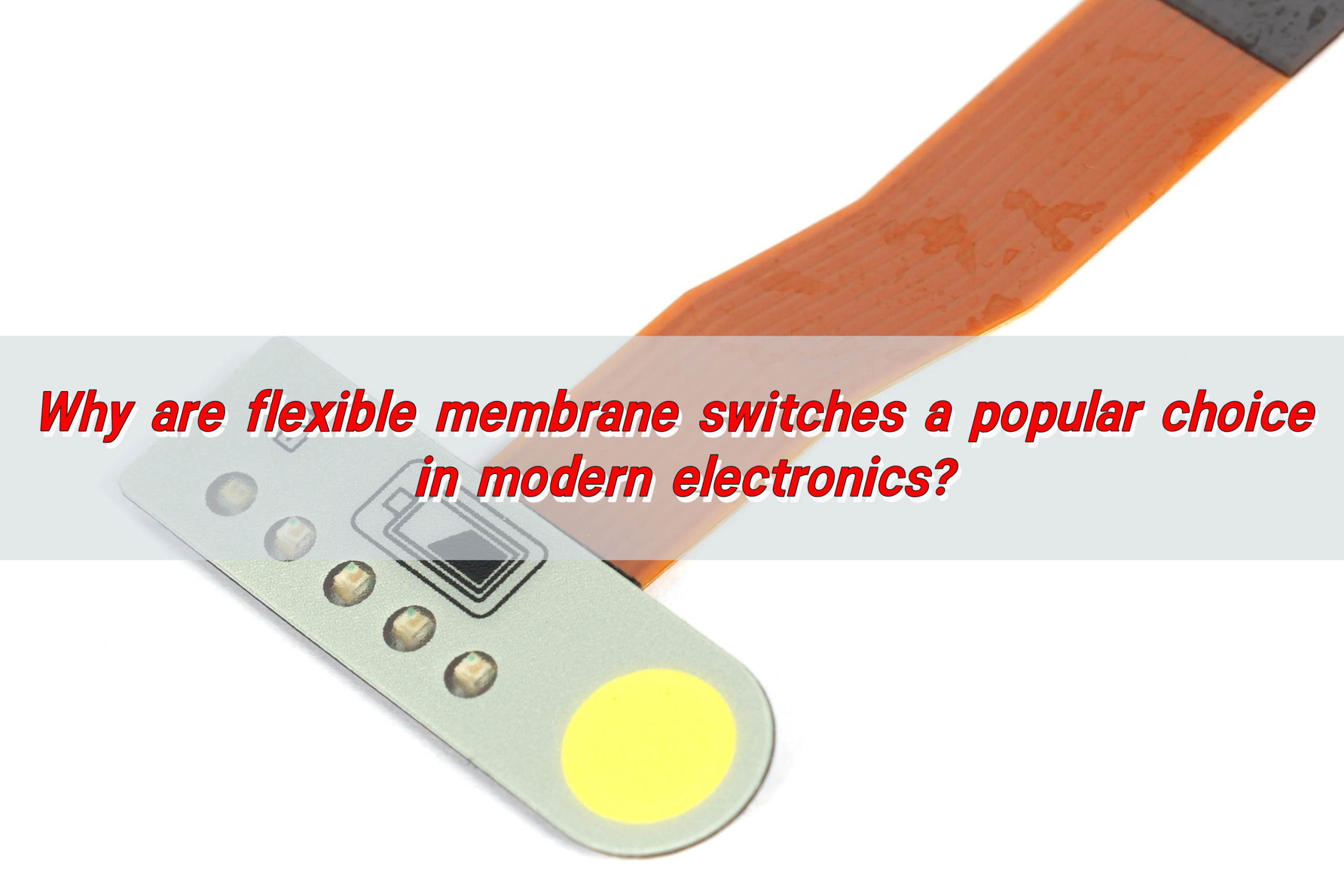

Why are flexible membrane switches a popular choice in modern electronics?

Flexible membrane switches are popular in modern electronic products due to their flexibility, thinness and economy. They not only adapt to complex curved surfaces and achieve flexible design, but also have environmental adaptability such as waterproof and dustproof. In addition, they support multi-function integration, such as LED indicators and sound feedback, to enhance user experience. ...

Contact us online