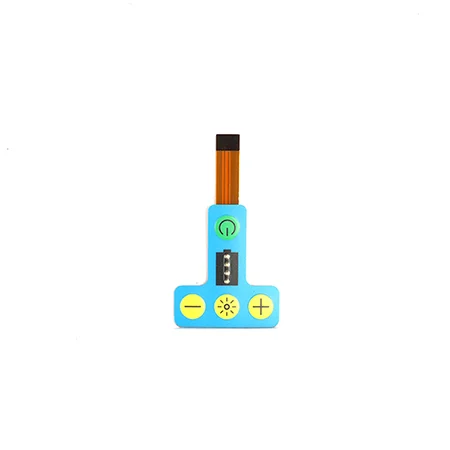

FPC Membrane Switch applied to Analytical instrument

FPC membrane switches are widely used in analytical instruments as integrated components that facilitate user interaction and control within these devices.

-

Panel material:PVC, PC, PET

-

Insulation resistance:>=100VDC

-

Rebound time:<=6ms

-

Loop resistance:≤ 80Ω (within 40cm of a single key return route)

-

Reliable life cycle:> 100times

| Basic Parameters of FPC Membrane Switch | |

| Max. Panel size | 600*800mm |

| Max. Panel size (with emboss) | 400*500mm |

| Paste | silver paste, carbon paste |

| Ink color | red, black, blue, white, yellow, green, purple, etc |

| Trace width | 0.15-0.20mm |

| LED spec. | 0402, 0603, 0805, 1210 |

| Wire length | Per customer requirements |

| Waterproof class | IP65 |

| Connector | female pin, male pin |

| Metal dome types | triangle, for-legs, circle |

| Trip force (metal dome) | 280g, 340g, 450g |

| Travel (metal dome) | 0.35-0.71 |

| Diameter (metal dome) | 8.4mm, 10mm, 12.2mm |

| Surface treatment (metal dome) | gold plating, nickle plating, stainless |

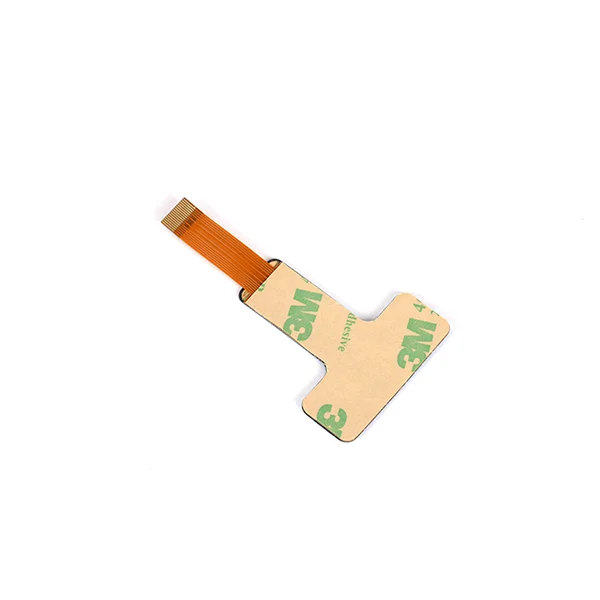

| Back adhesive | DSMS, 3M, SOKEN |

| Citcuit board option | FPC, PCB, Aluminum |

| Panel material | PET, PC, TPU, PMMA |

Tactile membrane switches offer tactile feedback in response to being activated by finger or actuator. This tactile feedback improves the user experience in scenarios where other types of feedback are limited or where it’s critical to confirm that the switch has been pressed. Tactile membrane switches offer tactile feedback in response to being activated by finger or actuator. This tactile feedback improves the user experience in scenarios where other types of feedback are limited or where it’s critical to confirm that the switch has been pressed.

Manufacturing of FPC Membrane Switch

FPC (Flexible Printed Circuit) membrane switch panels can be manufactured using either polyester or polyimide (such as Kapton) as the base material, depending on the specific interface requirements. The production process involves laminating a very thin sheet of copper onto the flexible film substrate. Subsequently, a chemical etching process is employed to remove excess copper, leaving behind the desired copper traces that form the circuit.

Compared to PET membrane switch panels, FPC indeed more expensive then it, and the most significant factor contributing to this cost difference is the substantial use of copper foil and, in some cases, gold (surface treatment). The prices of copper and gold are expected to continue rising in the future, potentially making FPC even more expensive compared to PET. The degree of cost increase varies depending on the specific product.

However, the higher cost of FPC is justified by its stability and reliability. FPC allows for dense lines to be concentrated on a small copper flex circuit. Additionally, the use of double panels and multi-panels enables the installation of more components in a smaller area, resulting in smaller product dimensions. This advantage is unmatched by PET circuits.

Additionally, FPC offers benefits in terms of electrical properties. Due to the absence of bridging and through-hole printing, products made with FPC tend to have lower resistance compared to those using PET. At the same time, the ZIF (Zero Insertion Force) tail of the FPC line can achieve a spacing as small as 0.05 mm, allowing for intricate and compact designs.

Contact us online